I.C.T-6534

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

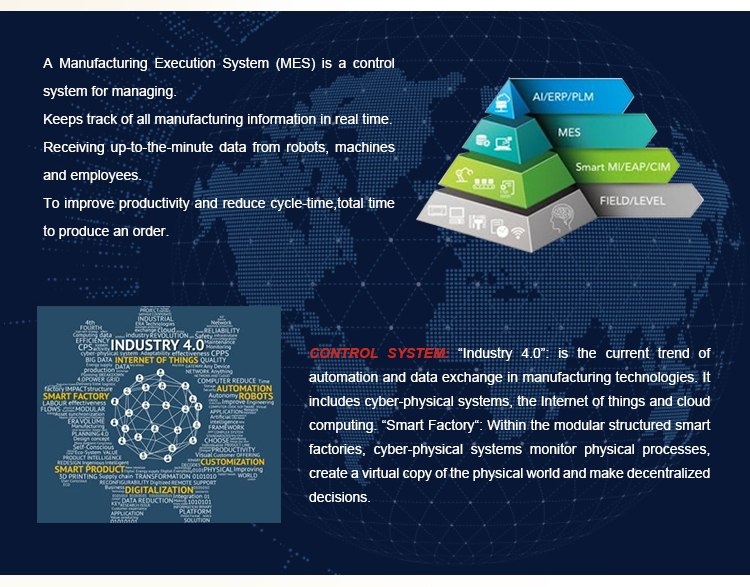

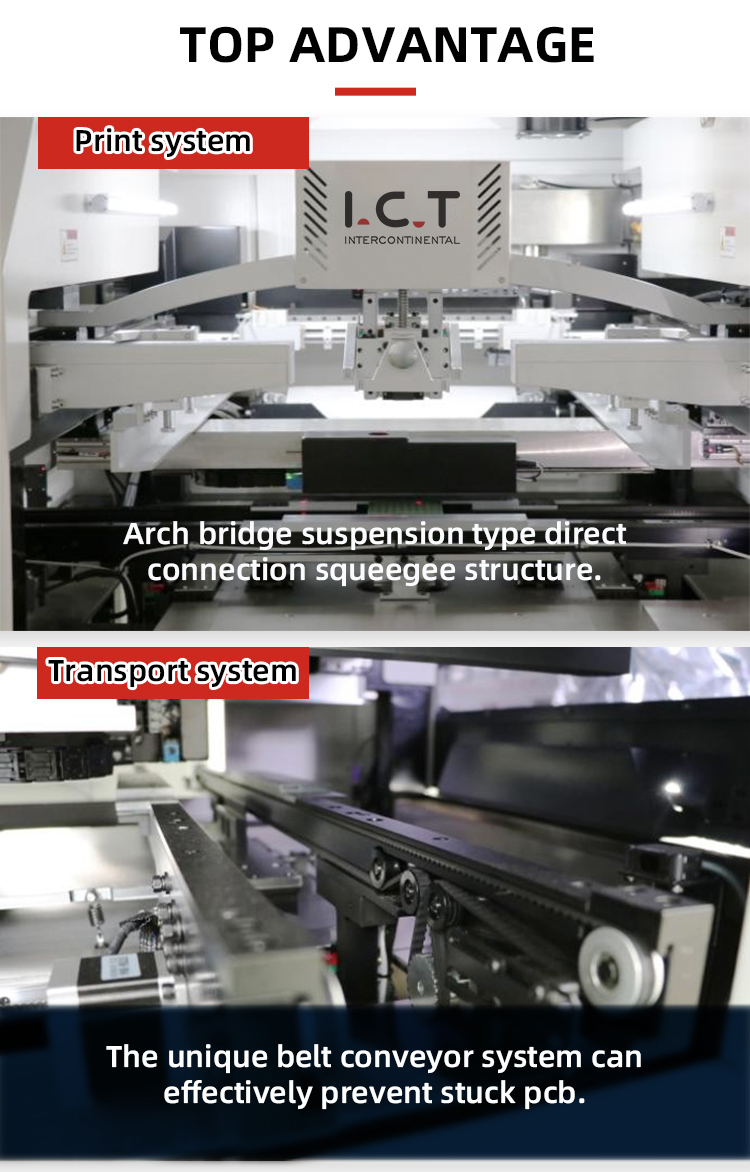

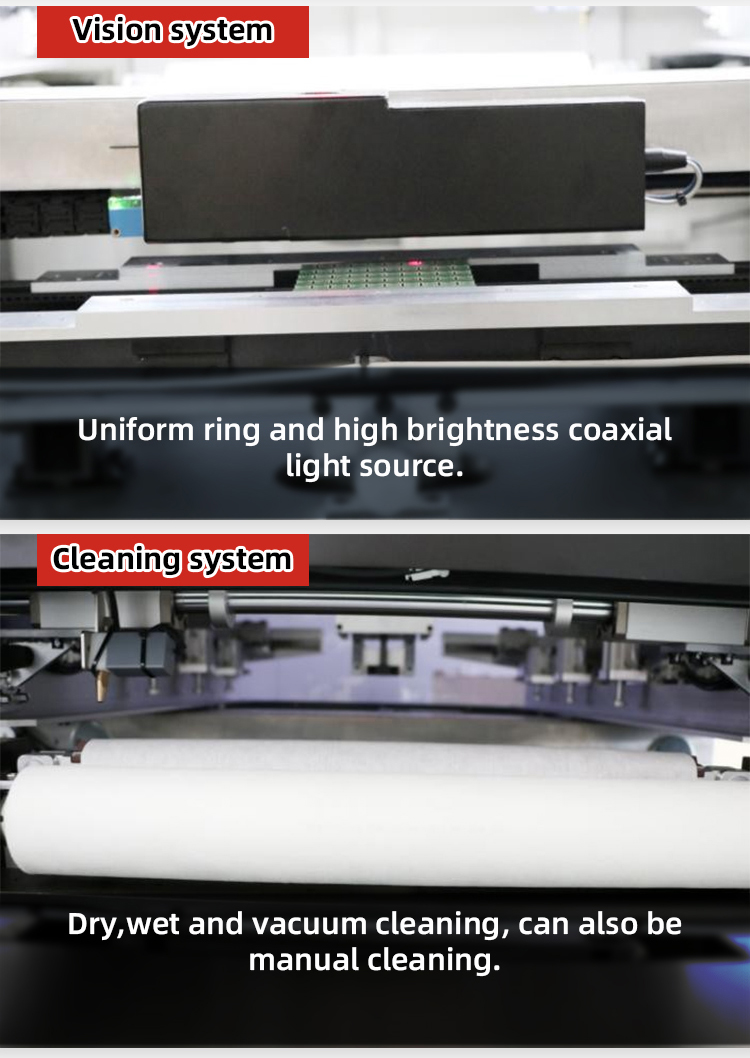

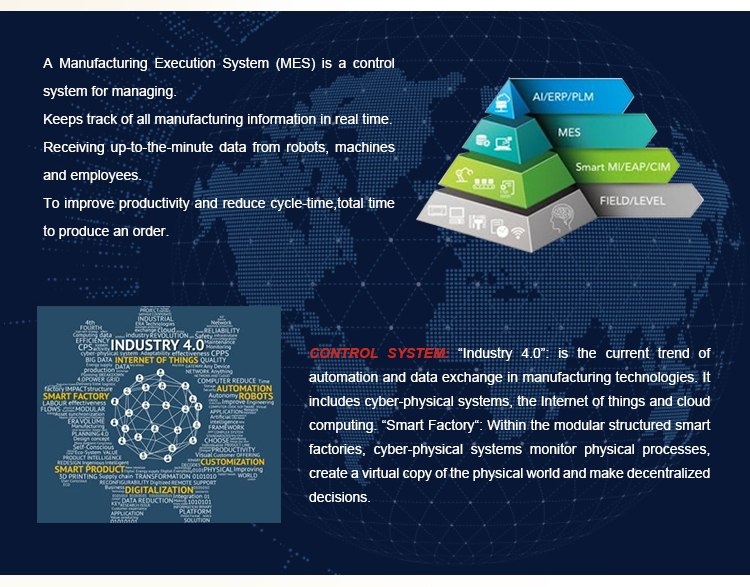

I.C.T Full-auto SMT Stencil Printer is a high precision automatic solder paste printer, correspond to industrial 4.0 and MES system.through a higher level of automation,achieve zero defect.

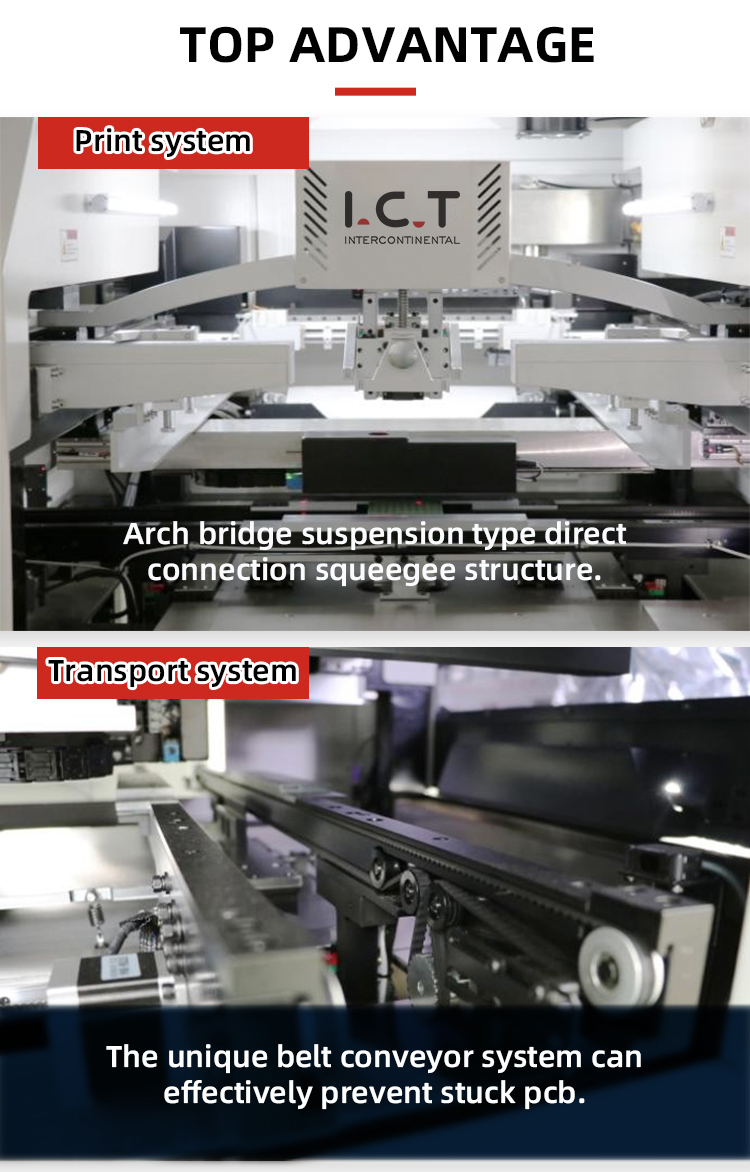

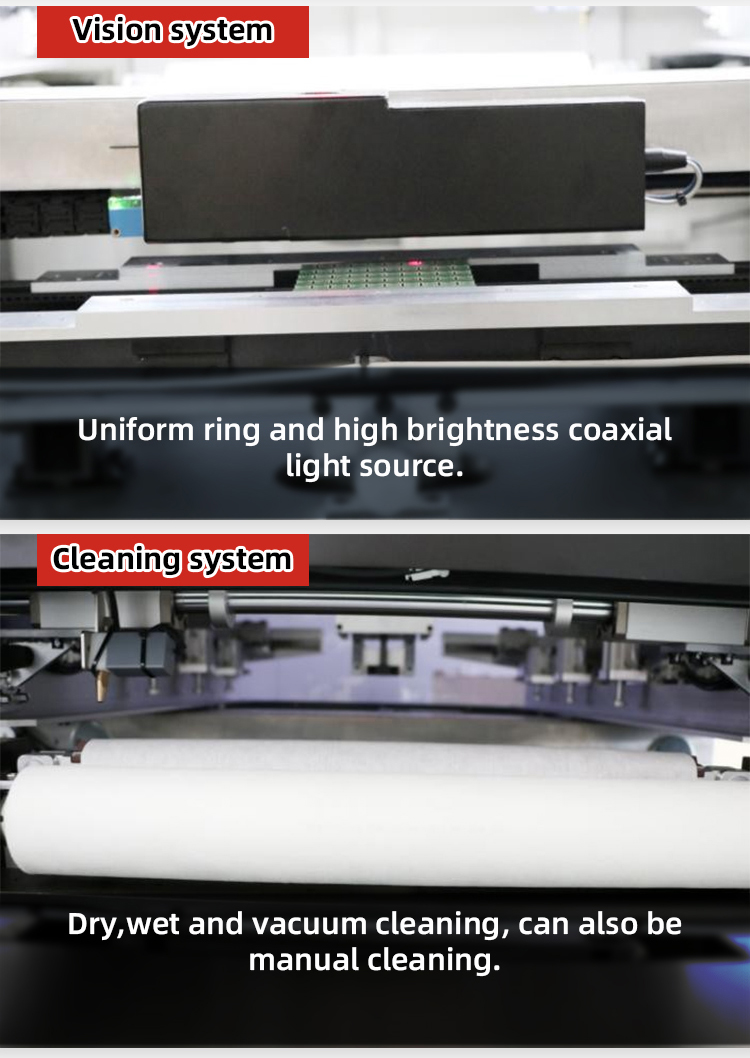

TOP Advantage:

1.Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to learn.

2.Expertise: learn imported reflow oven’s advanced design concepts, and the machine core components are using imported top brands.

3.Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

| Model | I.C.T-4034 | I.C.T5134 | I.C.T-5151 |

| Frame Size(mm) | 470*370 ~ 737*737 | 470*370 ~ 737*737 | 470*370 ~ 737*737 |

| PCB Size(mm) | 50*50 ~ 400*340 | 50*50 ~ 510*340 | 50*50 ~ 510*510 |

| Transport Direction | Left-Right; Right-Left; Left-Left; Right-Right | ||

| Support System | Magnetic Pin/Up-down table adjusted/support block | ||

| Clamping System | Side clamping(vacuum nozzle,Automation retractable Z pressure is option) | ||

| Printer Head | Two independent motorised printhead | ||

| Squeegee Type | Stainless steel(standard),plastic | ||

| Cleaning System | Dry, Wet, Vacuum | ||

| Inspection | 2D Inspection(Standard) | ||

| Power Supply | AC:220±10%,50/60HZ,3Kw | ||

| Control Method | PC Control | ||

| Dimension(mm) | 1220*1355*1500 | 1220*1355*1500 | 1220*1550*1500 |

| Model | I.C.T-6534 | I.C.T-6561 | I.C.T-9060 |

| Frame Size(mm) | 650*400 ~ 850*750 | 650*400 ~ 850*850 | 737*400 ~ 1100*900 |

| PCB Size(mm) | 50*50 ~ 650*340 | 80*50 ~ 650*610 | 80*50 ~ 900*600 |

| Dimension(mm) | 1330*1370*1500 | 1330*15450*1500 | 1580*1545*1500 |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T Full-auto SMT Stencil Printer is a high precision automatic solder paste printer, correspond to industrial 4.0 and MES system.through a higher level of automation,achieve zero defect.

TOP Advantage:

1.Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to learn.

2.Expertise: learn imported reflow oven’s advanced design concepts, and the machine core components are using imported top brands.

3.Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

| Model | I.C.T-4034 | I.C.T5134 | I.C.T-5151 |

| Frame Size(mm) | 470*370 ~ 737*737 | 470*370 ~ 737*737 | 470*370 ~ 737*737 |

| PCB Size(mm) | 50*50 ~ 400*340 | 50*50 ~ 510*340 | 50*50 ~ 510*510 |

| Transport Direction | Left-Right; Right-Left; Left-Left; Right-Right | ||

| Support System | Magnetic Pin/Up-down table adjusted/support block | ||

| Clamping System | Side clamping(vacuum nozzle,Automation retractable Z pressure is option) | ||

| Printer Head | Two independent motorised printhead | ||

| Squeegee Type | Stainless steel(standard),plastic | ||

| Cleaning System | Dry, Wet, Vacuum | ||

| Inspection | 2D Inspection(Standard) | ||

| Power Supply | AC:220±10%,50/60HZ,3Kw | ||

| Control Method | PC Control | ||

| Dimension(mm) | 1220*1355*1500 | 1220*1355*1500 | 1220*1550*1500 |

| Model | I.C.T-6534 | I.C.T-6561 | I.C.T-9060 |

| Frame Size(mm) | 650*400 ~ 850*750 | 650*400 ~ 850*850 | 737*400 ~ 1100*900 |

| PCB Size(mm) | 50*50 ~ 650*340 | 80*50 ~ 650*610 | 80*50 ~ 900*600 |

| Dimension(mm) | 1330*1370*1500 | 1330*15450*1500 | 1580*1545*1500 |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

FAQ:

1. What is an SMT Solder Paste Printing Machine?

An SMT (Surface Mount Technology) Solder Paste Printing Machine is a specialized equipment used in electronics manufacturing to accurately apply solder paste onto printed circuit boards (PCBs). This precise deposition of solder paste is crucial for the accurate placement of surface-mount components during the SMT assembly process.

2. How does an SMT Solder Paste Printing Machine work?

SMT Solder Paste Printing Machines use advanced printing technology to precisely deposit solder paste onto specific areas of a PCB. This ensures secure bonds and reliable connections for SMT components during assembly.

3. What are the key advantages of using an SMT Solder Paste Printing Machine?

Accuracy: These machines offer precise solder paste deposition, reducing defects in SMT assembly.

Efficiency: They automate the solder paste application process, saving time and improving consistency.

Versatility: SMT Solder Paste Printing Machines are compatible with various PCB sizes and designs.

Cost Savings: Minimized solder paste wastage contributes to cost efficiency.

4. In which industries are SMT Solder Paste Printing Machines commonly used?

SMT Solder Paste Printing Machines are essential equipment in industries like consumer electronics, automotive, aerospace, medical devices, telecommunications, and many others that rely on SMT assembly for PCB production.

5. Can SMT Solder Paste Printing Machines handle lead-free solder paste?

Yes, many SMT Solder Paste Printing Machines are designed to work with lead-free solder paste, ensuring compliance with environmental regulations and industry standards.

6. What factors should I consider when choosing an SMT Solder Paste Printing Machine?

When selecting an SMT Solder Paste Printing Machine, consider factors such as print speed, accuracy, PCB size compatibility, ease of maintenance, and the reputation of the manufacturer. It's crucial to choose a machine that aligns with your specific production requirements.

7. How do I maintain an SMT Solder Paste Printing Machine?

Regular maintenance includes cleaning the printer's stencil and nozzles, calibrating the machine, and ensuring the correct solder paste consistency. Consult the machine's user manual for detailed maintenance instructions.

8. Can an SMT Solder Paste Printing Machine improve production efficiency?

Yes, by automating the solder paste application process, SMT Solder Paste Printing Machines can significantly enhance production efficiency, reduce errors, and improve overall product quality.

FAQ:

1. What is an SMT Solder Paste Printing Machine?

An SMT (Surface Mount Technology) Solder Paste Printing Machine is a specialized equipment used in electronics manufacturing to accurately apply solder paste onto printed circuit boards (PCBs). This precise deposition of solder paste is crucial for the accurate placement of surface-mount components during the SMT assembly process.

2. How does an SMT Solder Paste Printing Machine work?

SMT Solder Paste Printing Machines use advanced printing technology to precisely deposit solder paste onto specific areas of a PCB. This ensures secure bonds and reliable connections for SMT components during assembly.

3. What are the key advantages of using an SMT Solder Paste Printing Machine?

Accuracy: These machines offer precise solder paste deposition, reducing defects in SMT assembly.

Efficiency: They automate the solder paste application process, saving time and improving consistency.

Versatility: SMT Solder Paste Printing Machines are compatible with various PCB sizes and designs.

Cost Savings: Minimized solder paste wastage contributes to cost efficiency.

4. In which industries are SMT Solder Paste Printing Machines commonly used?

SMT Solder Paste Printing Machines are essential equipment in industries like consumer electronics, automotive, aerospace, medical devices, telecommunications, and many others that rely on SMT assembly for PCB production.

5. Can SMT Solder Paste Printing Machines handle lead-free solder paste?

Yes, many SMT Solder Paste Printing Machines are designed to work with lead-free solder paste, ensuring compliance with environmental regulations and industry standards.

6. What factors should I consider when choosing an SMT Solder Paste Printing Machine?

When selecting an SMT Solder Paste Printing Machine, consider factors such as print speed, accuracy, PCB size compatibility, ease of maintenance, and the reputation of the manufacturer. It's crucial to choose a machine that aligns with your specific production requirements.

7. How do I maintain an SMT Solder Paste Printing Machine?

Regular maintenance includes cleaning the printer's stencil and nozzles, calibrating the machine, and ensuring the correct solder paste consistency. Consult the machine's user manual for detailed maintenance instructions.

8. Can an SMT Solder Paste Printing Machine improve production efficiency?

Yes, by automating the solder paste application process, SMT Solder Paste Printing Machines can significantly enhance production efficiency, reduce errors, and improve overall product quality.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT