Views: 0 Author: Site Editor Publish Time: 2024-03-29 Origin: Site

In the ever-evolving landscape of security technology, the demand for advanced surveillance systems continues to surge. Among the indispensable components of these systems are cameras, serving as the vigilant eyes safeguarding properties and lives. As the security industry progresses, so do the expectations for enhanced functionalities, durability, and efficiency in security camera production.

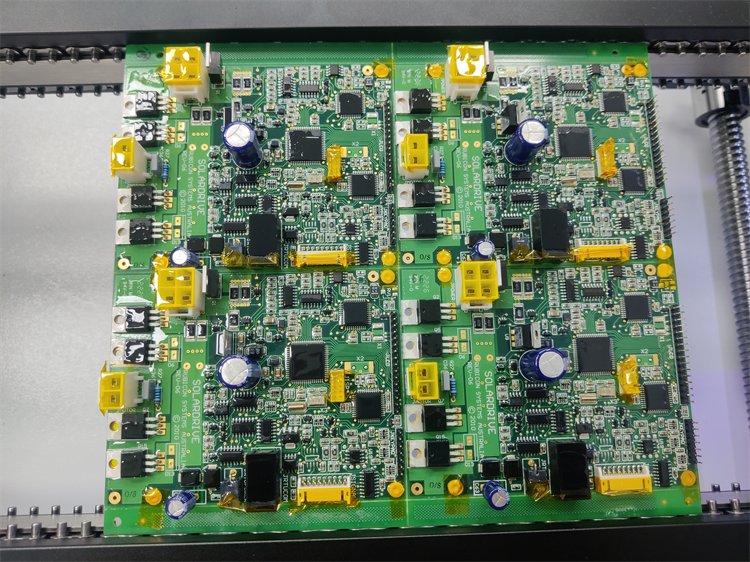

One critical aspect of camera manufacturing lies in the Printed Circuit Board Assembly. PCBA coating process. Recently, a notable advancement in this domain occurred with the development of a comprehensive PCBA coating solution customized for a specific client's needs.

The security camera industry has witnessed exponential growth, fueled by escalating security concerns globally. From commercial establishments to residential properties and public spaces, the demand for surveillance solutions is pervasive. This trend is further propelled by technological advancements, including AI integration, high-resolution imaging, and IoT connectivity, promising more sophisticated and efficient security systems.

Amidst this growth, manufacturers face the dual challenge of meeting market demands while ensuring the reliability and quality of their products. The coating of PCBAs is a critical step in this process, as it not only protects the delicate components from environmental factors but also ensures the longevity and performance of the camera system.

One of our clients encountered significant hurdles in their PCB board manufacturing process. The primary challenges revolved around component irregularities and the prohibition of adhesive application within the insertion ports. These issues posed substantial obstacles to achieving uniform coating and reliable product performance.

To address these challenges, our team devised a tailored solution leveraging advanced technology and innovative engineering. Central to our approach was the integration of a combination of needle valves and atomizing valves in our coating equipment. This dual-system allowed for precise application tailored to the intricate contours of the PCB components.

Moreover, the inclusion of a 360-degree rotating head (U-axis) in our equipment offered unparalleled flexibility in coating application. This feature enabled targeted spraying of adhesive within the insertion ports without compromising on precision or efficiency. By optimizing the coating process with this advanced equipment, we effectively mitigated the client's manufacturing challenges, ensuring consistent quality and performance in their security camera products.

The adoption of our tailored PCBA coating solution resulted in a significant enhancement in overall efficiency for our client's production line. The combination of needle valves and atomizing valves facilitated both pinpoint accuracy in coating application and broad coverage, optimizing material usage and minimizing wastage.

Furthermore, the incorporation of the U-axis rotation further streamlined the manufacturing process, allowing seamless adaptation to varying PCB geometries and configurations. This not only addressed the existing challenges but also future-proofed the production line against potential design iterations or product enhancements.

In conclusion, the collaboration between our team and the client exemplifies the synergy between innovation and industry-specific solutions in addressing complex manufacturing challenges. By understanding the intricacies of security camera production and tailoring our coating solution to meet the client's precise requirements.

For you we can provide Full SMT Line Solution, DIP Line Solution and Coating Line Solution with best quality and service.

More information about I.C.T please Contact US at info@smt11.com