Views: 0 Author: Site Editor Publish Time: 2023-03-24 Origin: Site

Routers, controllers and set-top boxes are important components of network technology. They have different functions, but they all provide great convenience for the network.

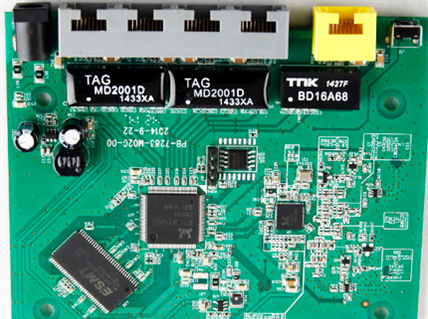

Router is the core device of network, its main function is to connect multiple networks, and can control the flow of data. It can detect network packets and forward them to the correct location based on the address information contained in them.

A controller is a device used to control network devices. It can manage network devices, such as routers, switches, and set-top boxes, and control their functions and performance.

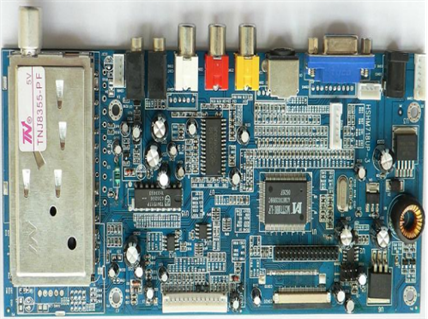

A set-top box is a device designed to receive and send digital signals. It can receive cable TV signals, or wireless signals, and convert them into visual TV signals for the user to watch TV programs.

In short, routers, controllers, and set-top boxes are all important components of networking technology. They all have different functions, but they all provide great convenience for the network.

The production and manufacturing of these products are inseparable from SMT and DIP production processes.

TV Set-top Box PCBA

Router PCBA

Controller PCBA

SMT Full-line Solutions are known for their advanced technology and outstanding performance, providing strong support for consumer electronics. It effectively improves the performance and reliability of electronic products with an efficient and reliable production mode, while reducing production costs and time, improving efficiency, reducing costs, and maximizing product quality. Therefore, the SMT full-line solution is ideal for consumer electronics manufacturers to help them get their products to market faster.

DIP Full-line Solutions provide a comprehensive solution for consumer electronics designed to meet the needs of the consumer electronics industry. It provides a variety of components, including connectors, switches, resistors, capacitors, integrated circuits, and other components. In addition, it provides complete manufacturing and assembly services, including welding, molding and testing. The solution is designed to provide affordable and reliable solutions for consumer electronics. It is also highly customizable, allowing manufacturers to tailor their products to their specific requirements.

If you want to know more about SMT solution for Consumer Electronics Products according to your PCB board, please Contact Us for freely.

Following are the Solution for your reference.

SMT Full-line Solution equipment as follows: : 1 person to operate the whole line, 1 person to assist, total 2 people.

- Automatic PCB Loader - Full-auto Printing Machine - 3D SPI - PCB Conveyor - 2 sets SMT Pick and Place Machine - PCB Conveyor - Reflow Oven (8-10 zones) - PCB Cooling Conveyor - On-line AOI - NG/OK Unloader

DIP Full-line Solution equipment as follows: Personnel are adjusted according to the product, 8-20 people.

- 9m Insertion Line

- Wave Loader

- External sprayer

- High-end Arcrab Series Lead-free Wave Soldering Machine

- Wave Unloader

| SMT | Capacity Evaluation | 2 sets pick and place machine; production capacity 35,000-45,000CHIP/H | ||||

| Total Power | 80 KW | Operating Power | 17KW | |||

| Applicable Product | SMD components within 100pcs, 0201-45mm, max PCB width 350mm | |||||

| DIP | Capacity Evaluation | Calculated based on the number of componens and the operators | ||||

| Total Power | 35.5 KW | Operating Power | 10.5 KW | |||

| Applicable Product | Medium and high-end products requirements, Max PCB width 350mm | |||||

| SMT+ DIP | Workshop Size | L30m x W15m , total area 450 ㎡ | ||||

If you are a factory to produce Consumer Electronics prodcuts, or want to build a new SMT factory, please contact us for turnkey SMT Solution.

Video for your reference:

For you we can provide Full SMT Line Solution, DIP Line Solution and Coating Line Solution with best quality and service.

More information about I.C.T please contact US at info@smt11.com