Security Monitoring System

The monitoring system is one of the most widely used systems in the security system.

For Monitroing Equipment Production, we can provide full SMT and DIP line Machine for PCB Assembly.

The most suitable site monitoring system on the market now is the handheld video communication equipment, and video monitoring is now the mainstream. From the earliest analog monitoring to digital monitoring and then to network video monitoring, earth-shaking changes have taken place.

Today, IP technology is gradually unified around the world. From the perspective of SMT technology, let's take a look at PCB assembly of monitoring equipment.

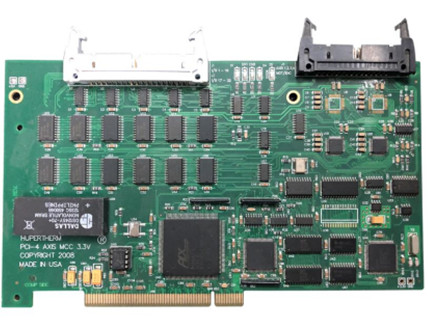

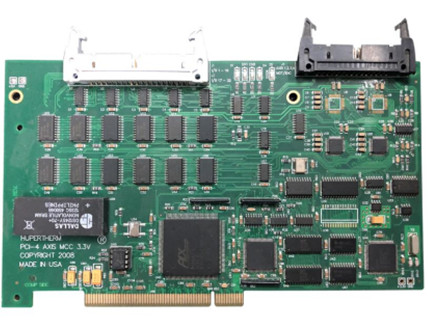

Video Signal Acquisition card PCBA

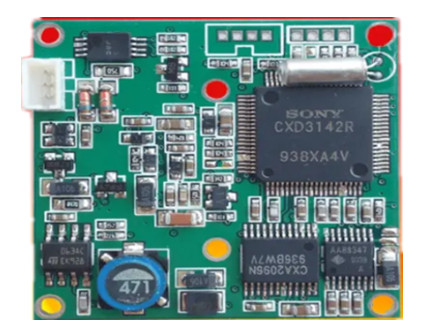

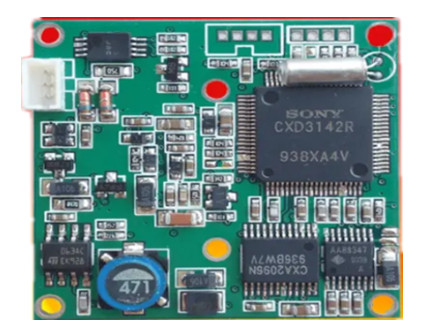

Monitoring Equipment PCBA

Camera PCBA

Technological Process: SMT and DIP

What is SMT ?

SMT is short for Surface Mount Technology.

It is a circuit assembly technology that directly mounts surface mount components on the PCB (Printed Circuit Board) without through holes, and solders them to the specified position on the surface of the printed circuit board.

SMT Process: Solder Paste (Red Glue) Printing --> Components Mounting --> Reflow Soldering --> AOI Optical Inspection

Economical full-auto SMT Line equipment as follows: : 1 person to operate the whole line, 1 person to test AOI, total 2 people.

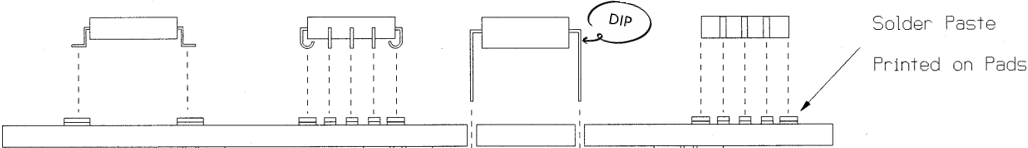

What is DIP ?

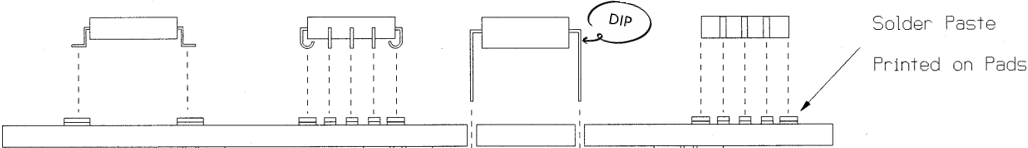

DIP is short for Dual In-line Package.

It is a type of component package. But it is traditionally used to refer to THT (Through Hole Technology).

It is a circuit assembly technology that inserts the component lead into the reserved through hole on the PCB, temporarily fixes and welds it on the other side of the substrate to form a reliable welding spot.

DIP Process: Plug-in --> Welding --> Maintenance --> PCB Cutting

Economical DIP Line equipment as follows: Personnel are adjusted according to the product, 3-15 people.

Solution Data:

| SMT | Capacity Evaluation | 1 set pick and place machine; production capacity 20000-25000CHIP/H |

| Total Power | 59.5 KW | Operating Power | 14.5KW |

| Applicable Product | SMD components within 50pcs, 0201-42mm, max PCB width 350mm

|

| DIP | Capacity Evaluation | Calculated based on the number of componens and the operators |

| Total Power | 16.8 KW

| Operating Power | 5.8 KW |

| Applicable Product | Low capacity requirements or simple products, Max PCB width 350mm |

SMT+ DIP

| Workshop Size | L20m x W15m , total area 300 ㎡

|

If you are factory to produce security monitoring euipment, need suitable full line solution, please contact us for more details.

Video for your reference:

I.C.T - Your Reliable Dearest Partner

For you we can provide Full SMT Solution, DIP Solution and Coating Solution with best quality and service.

More information about I.C.T please contact US at info@smt11.com

English

English