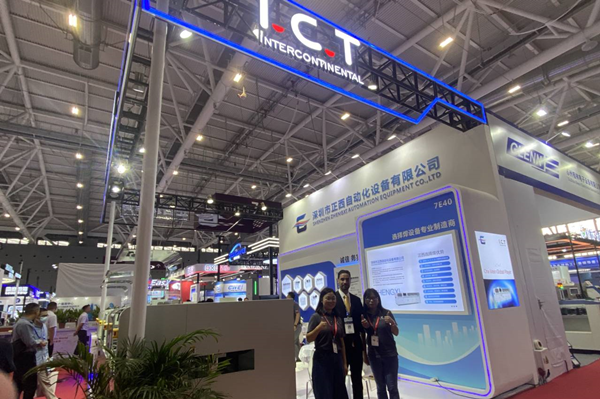

I.C.T - Your one-stop SMT & DIP solution for LED LENS

Excited to announce that following a successful case in the LED industry in May, I.C.T's SMT engineer Lucas will be offering technical support to a new customer in LED industry (LED Lens) in Malaysia on July 15th.

Follow us for the latest updates on LED LENS solutions and projects.

This LED LENS Production Line machines inculded Semi-auto Solder Paste Printer, SMT Conveyor, online Dispensing Machine, Pick and Place Machine SM481Plus, Bowl Feeder, 8 Zone Reflow Oven, PCB Cooling Conveyor,

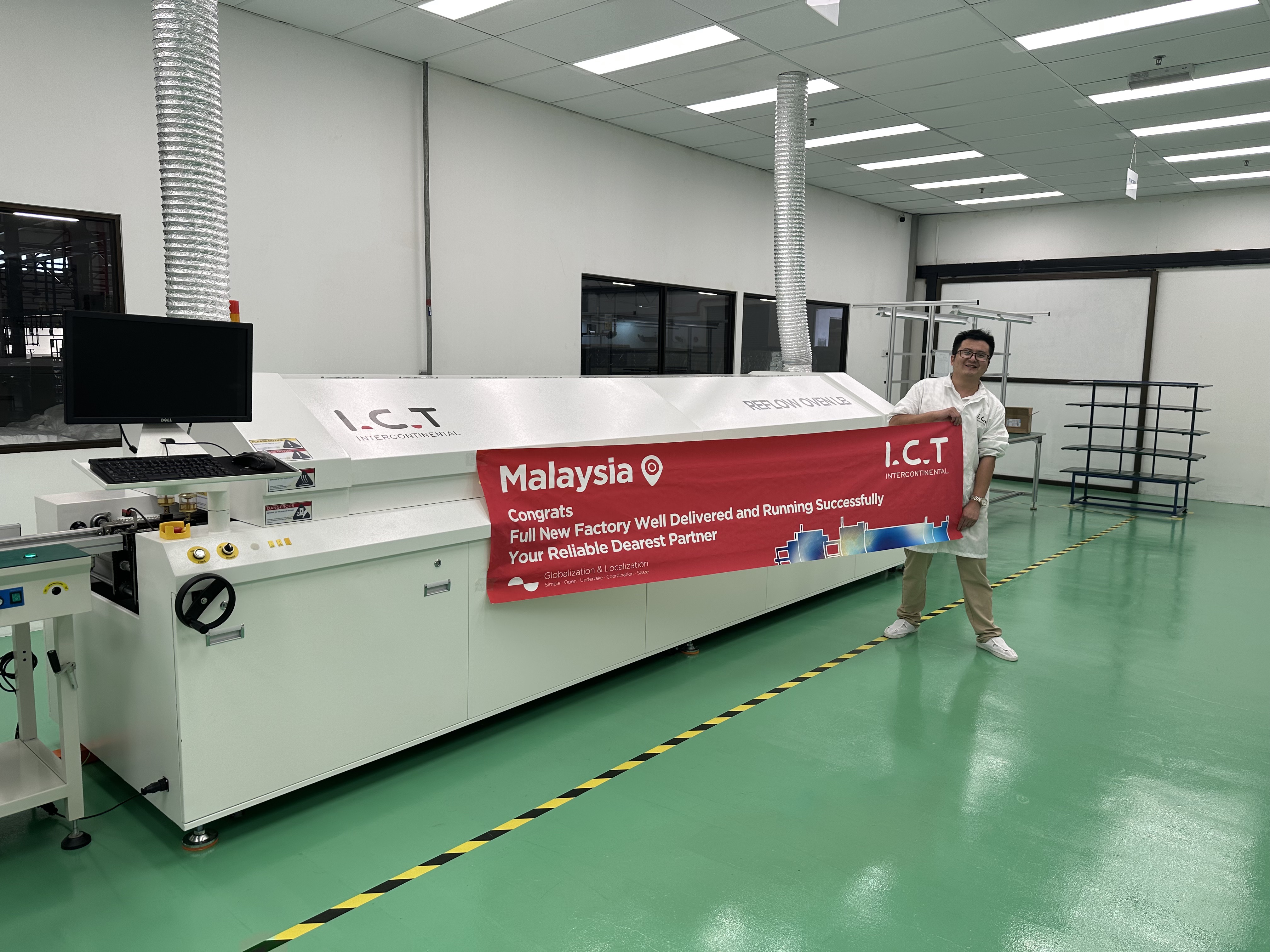

With our more than 25 years SMT experience and customized solution, our SMT technical engineers will assist in selecting the right machine, factory layout, installation, training and after-sales services to ensure successfully delivered and put into production.

We invite business in related to contact us for one-stop SMT & DIP solution to your factory.

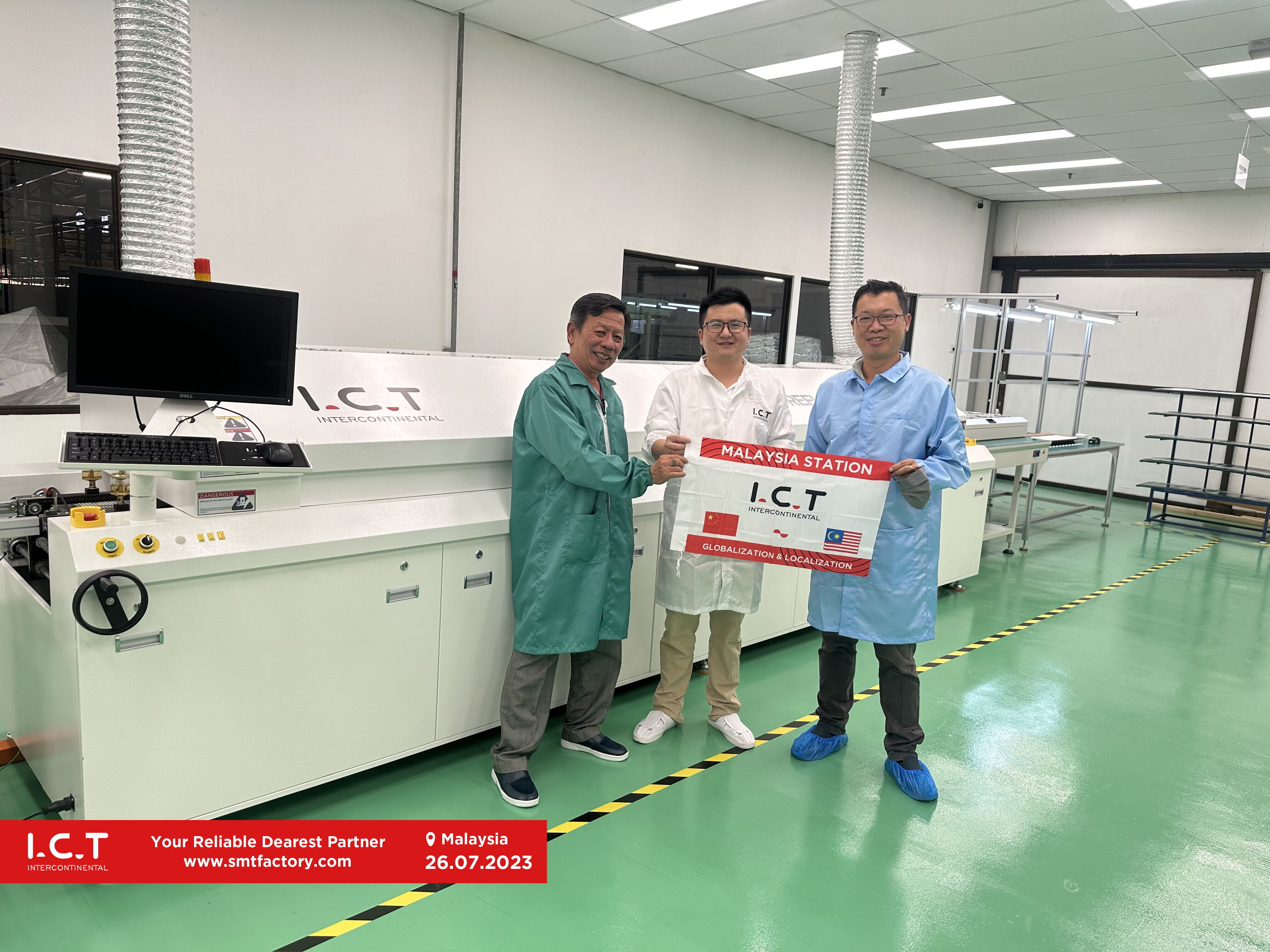

I.C.T | Global Services in Malaysia

Full new factory well delivered and running successfully.

Next stop: Thailand

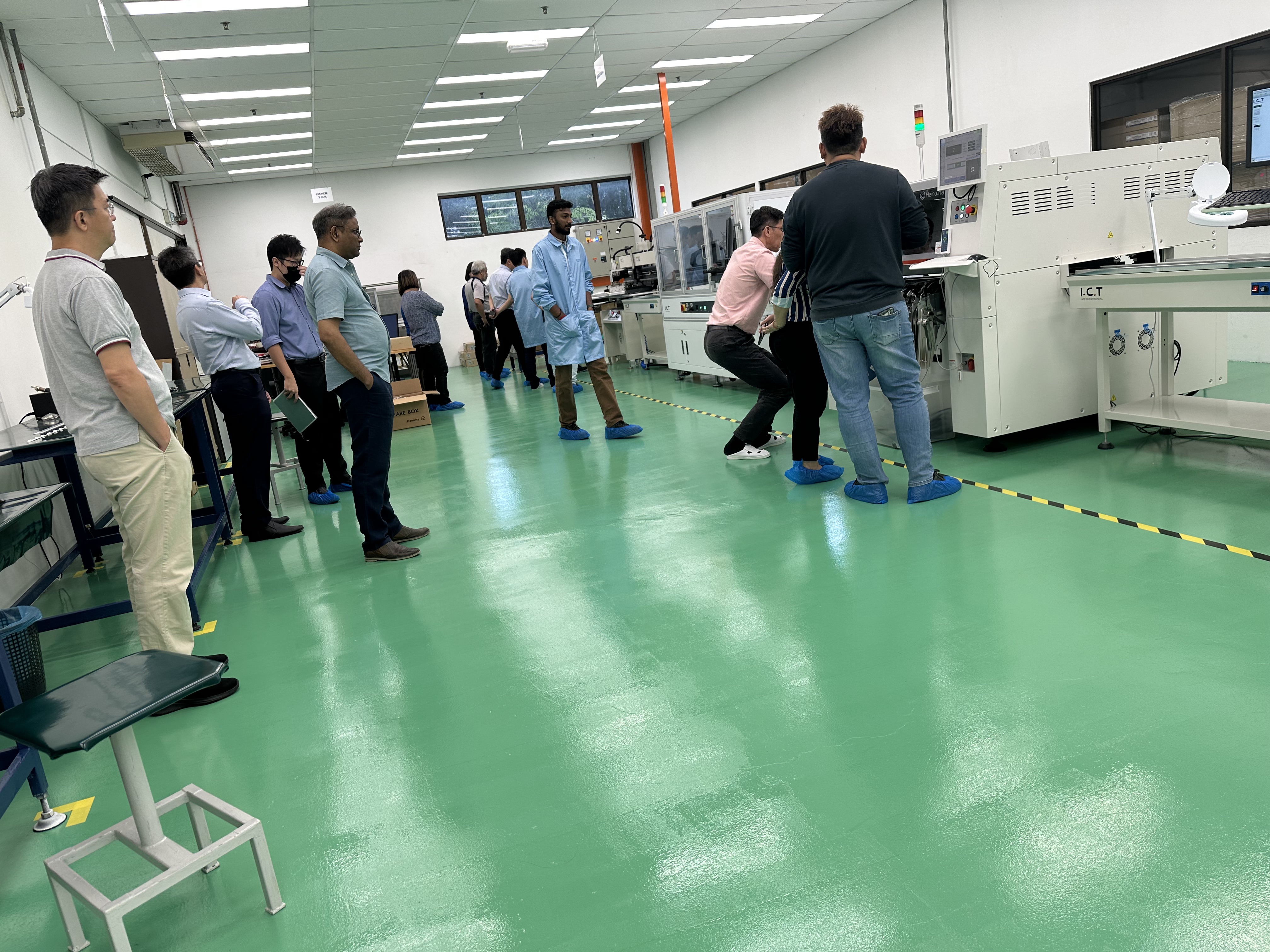

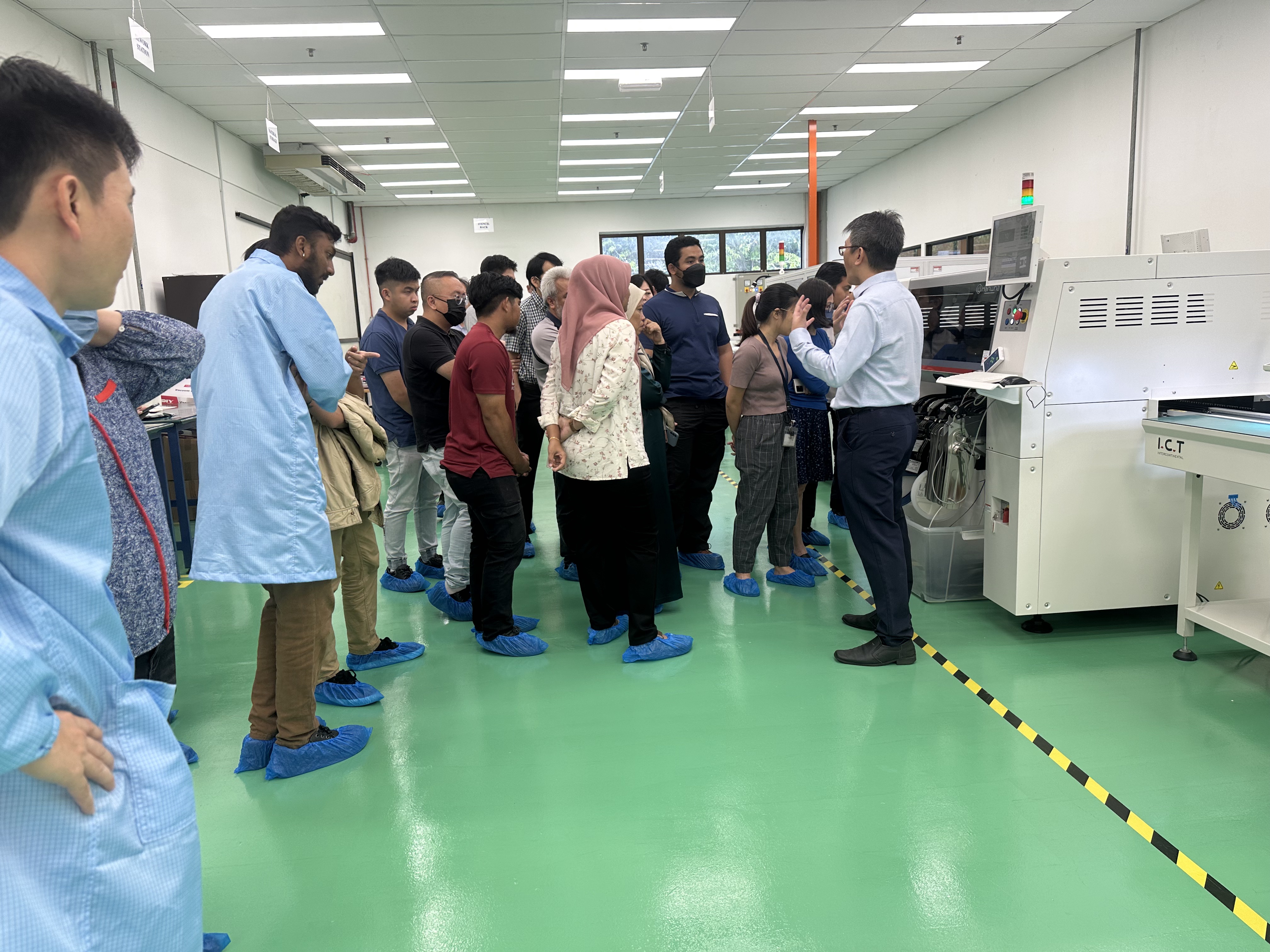

After the successful installation and commissioning of the LED LENS production line, our team of professional engineers provided comprehensive equipment training to our customer, covering key devices such as the SMT printing machine, PCB dispensing machine, pick-and-place machine, and reflow soldering oven. We deeply understand the significance of equipment training for our customer production operations; therefore, we are committed to ensuring that our customer engineers can proficiently operate this production line, fully harnessing the capabilities of the equipment to enhance production efficiency and product quality.

Successfully set up the LED LENS production line

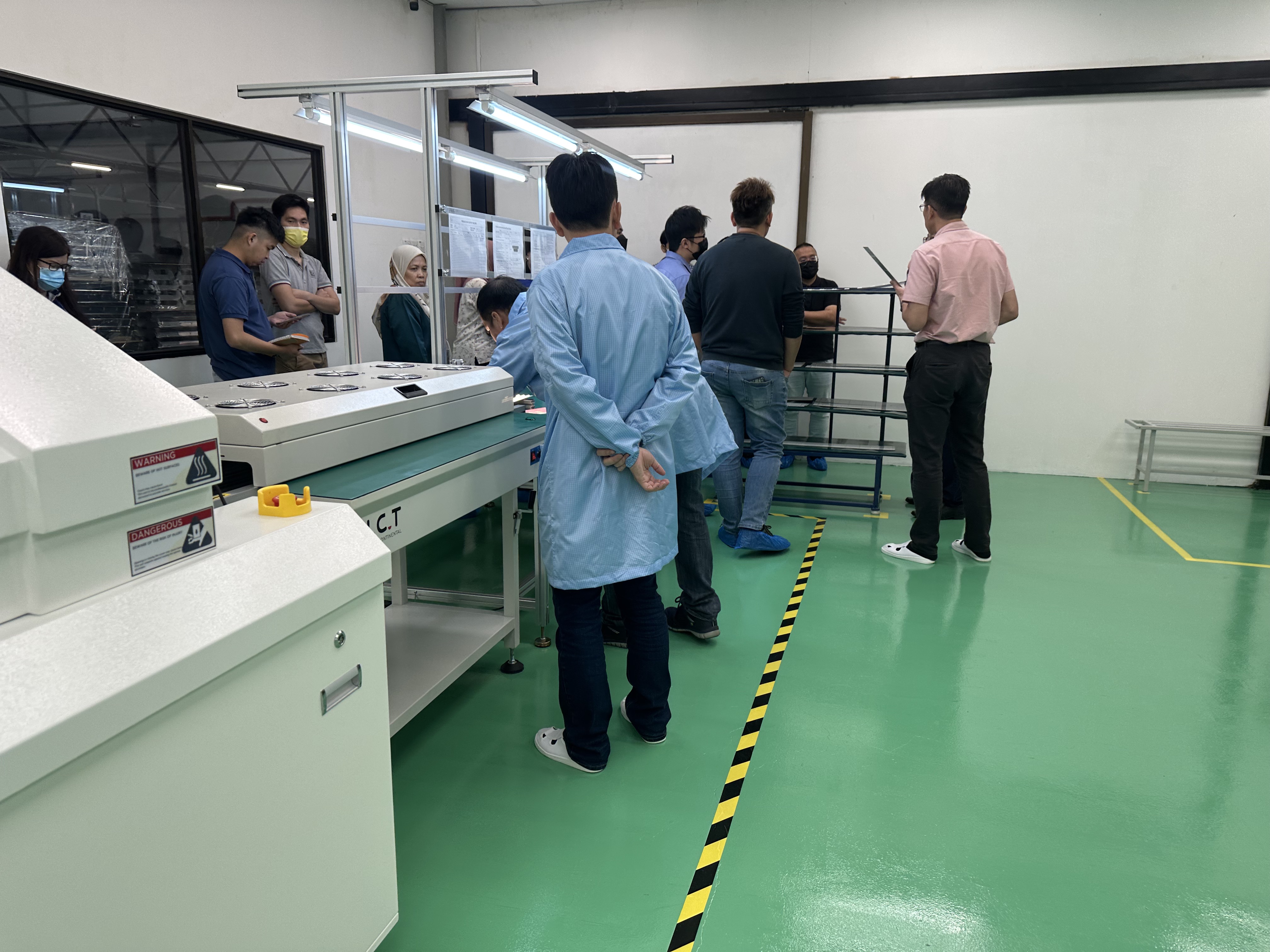

The engineers successfully set up the LED LENS production line. During the process, the engineers carried out precise debugging and testing of the SMT Printing Machine, LED Dispensing Machine, SAMSUNG Pick and Place Machine and Bowl Feeder, as well as the Reflow Oven to ensure the normal operation and stability of these key equipments.

English

English