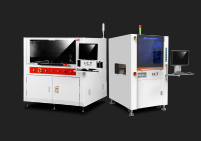

High-end NG Buffer

High-end NG Buffer This device can cache AOI or SPI and other testing machine out of the NG and OK board, OK board will flow to the next process, and the NG board will flow to the upper conveyor to wait for manual confirmation.

Transmission with durable roller (no need to replace the belt)

Small machine footprint.

Fast, smooth and accurate retri

Parallel and smooth width adju

Three operation modes: FIFO, LIFO, Pass-through.

Compatible SMEMA interfa.

Specification of PCB Buffer

| Model | NB-L |

| Dimension(mm) | 1000*790*1650 |

| PCB Size(mm) | 50*50-460*350 |

| Cycle Time | Approx.10 Seconds |

| PCB Capacity | 20pcs or Specify |

| Control System | PLC |

| Power | Max 250 VA |

| Transport Height | 900±20mm (or Customer Specified) |

| PCB Direction | L to R or R to L |

| Communication | SMEMA for Both In & Out |

| Power Supply | 1 PH AC 220V 50/60Hz (Option: 110V to 380V) |

| Weight | 300 Kg |

NG Buffer Key Features and Application Scenarios

NG Buffer Models: The NG Buffer is available in models NB-L and NB-XL. The minimum PCB size it supports is 50mm x 50mm, while the maximum PCB sizes are 460mm x 350mm and 530mm x 460mm, respectively.

Application Scenarios: The NG Buffer is primarily used in SMT production lines, particularly after SPI (Solder Paste Inspection), to buffer PCBs for manual inspection of printed solder paste.

By integrating the NG Buffer into the production line, you can effectively manage PCB flow and ensure high-quality inspection processes.

English

English