I.C.T-PP3025

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Features:

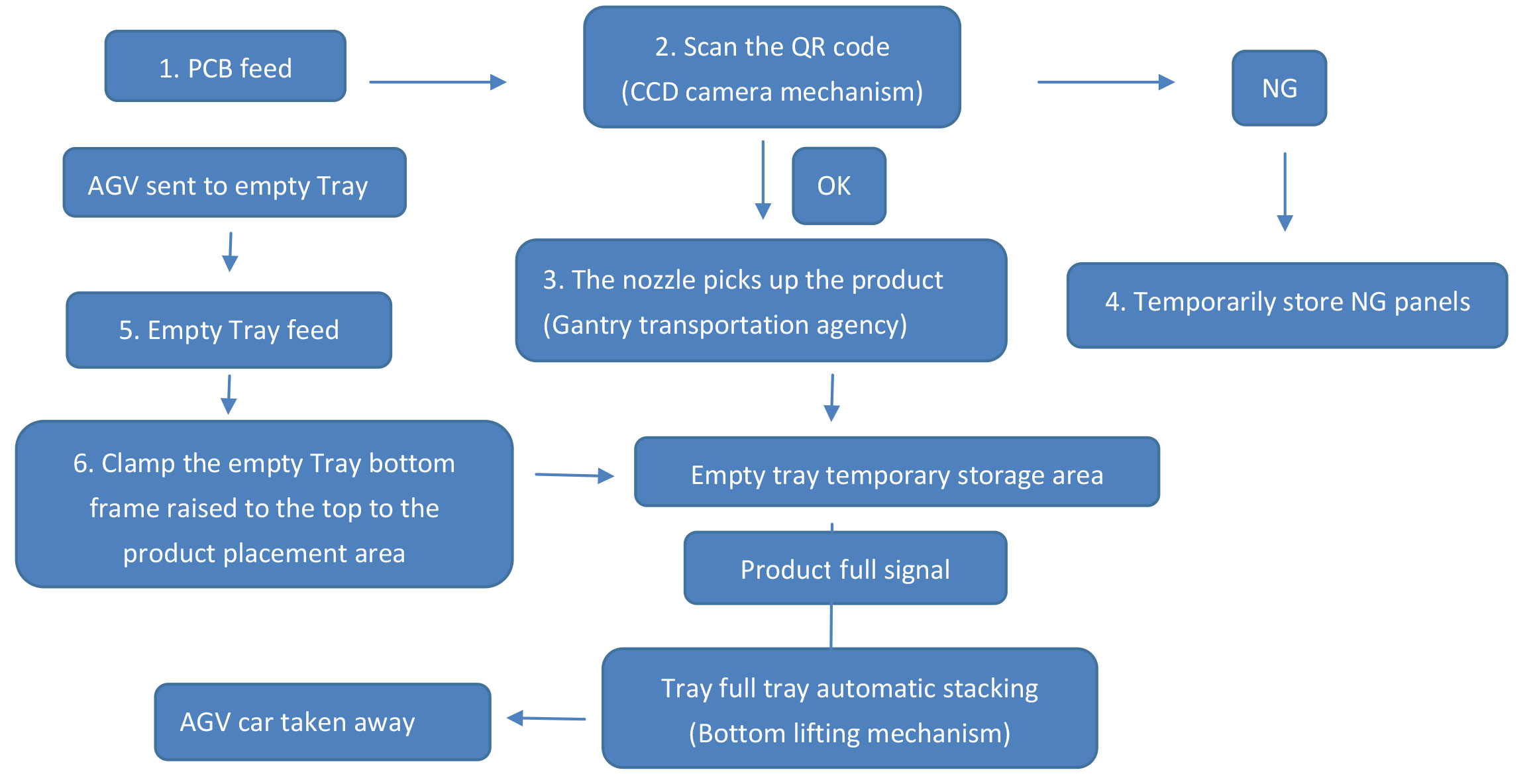

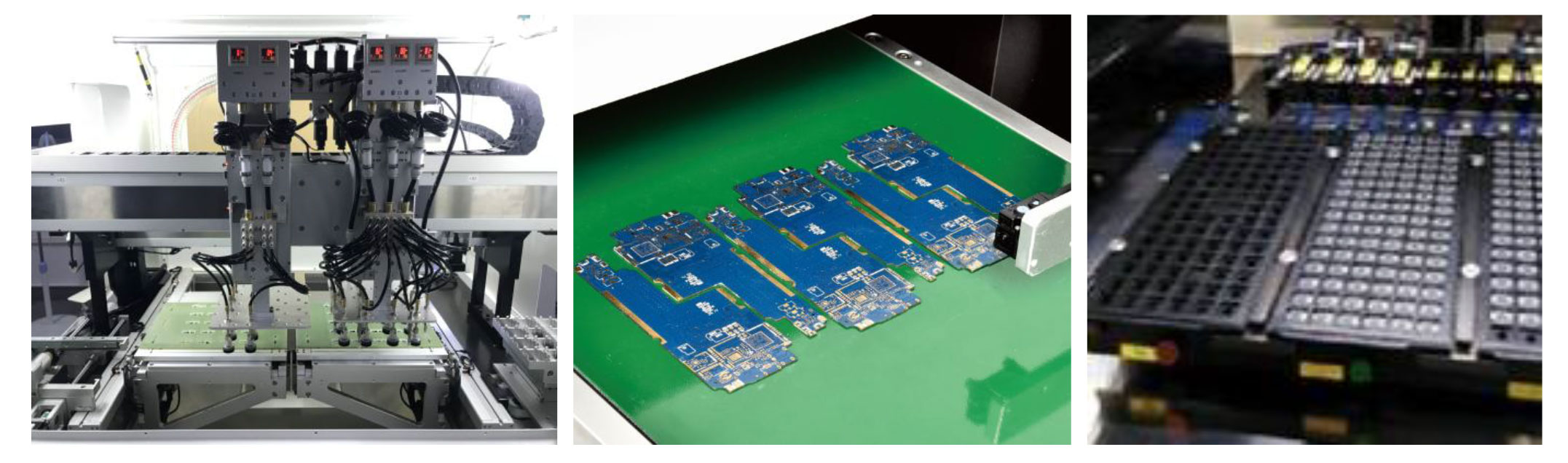

1. Automatic feeding: auto feed the products to be placed in the plate after receiving the signal from the front machine.

2. Automatic code scanning: CCD detects the product size and has the code scanning function at the same time.

3. Automatic pan: CCD guides the suction nozzle to automatically suck OK products to pan.

4. Automatically distinguish NG code: NG products are automatically put into the NG plate, and the NG code and fork plate are put into the defective box.

5. Automatic stacking tray: automatically supply empty trays and stacking OK finished trays full trays.

6. AGV automatically feeds in empty trays and takes away full trays.

7. Adopt multi-axis bus control. 8. Production capacity: production capacity is about 1800-2000pcs/H

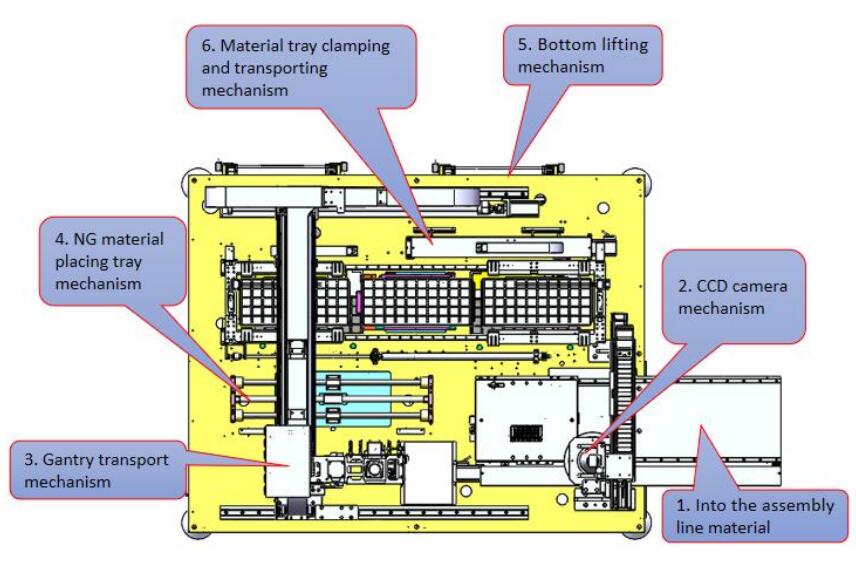

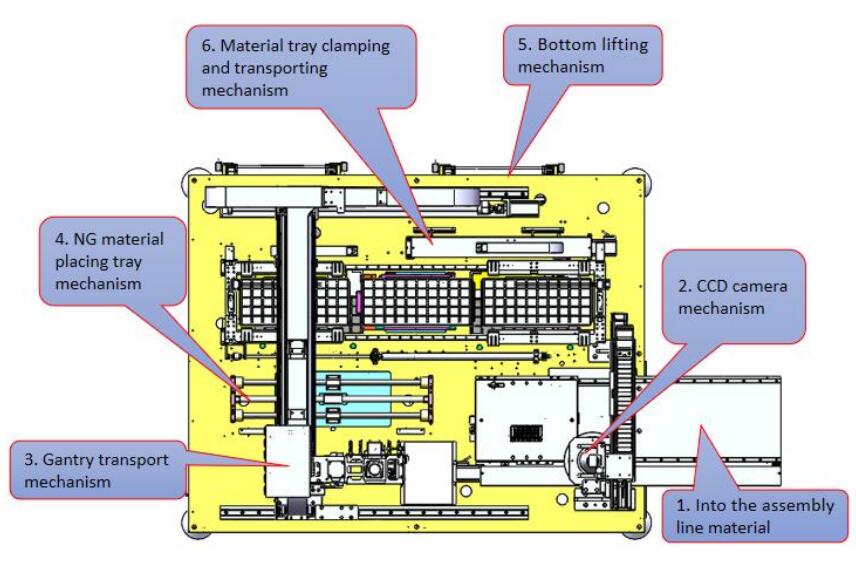

Structure:

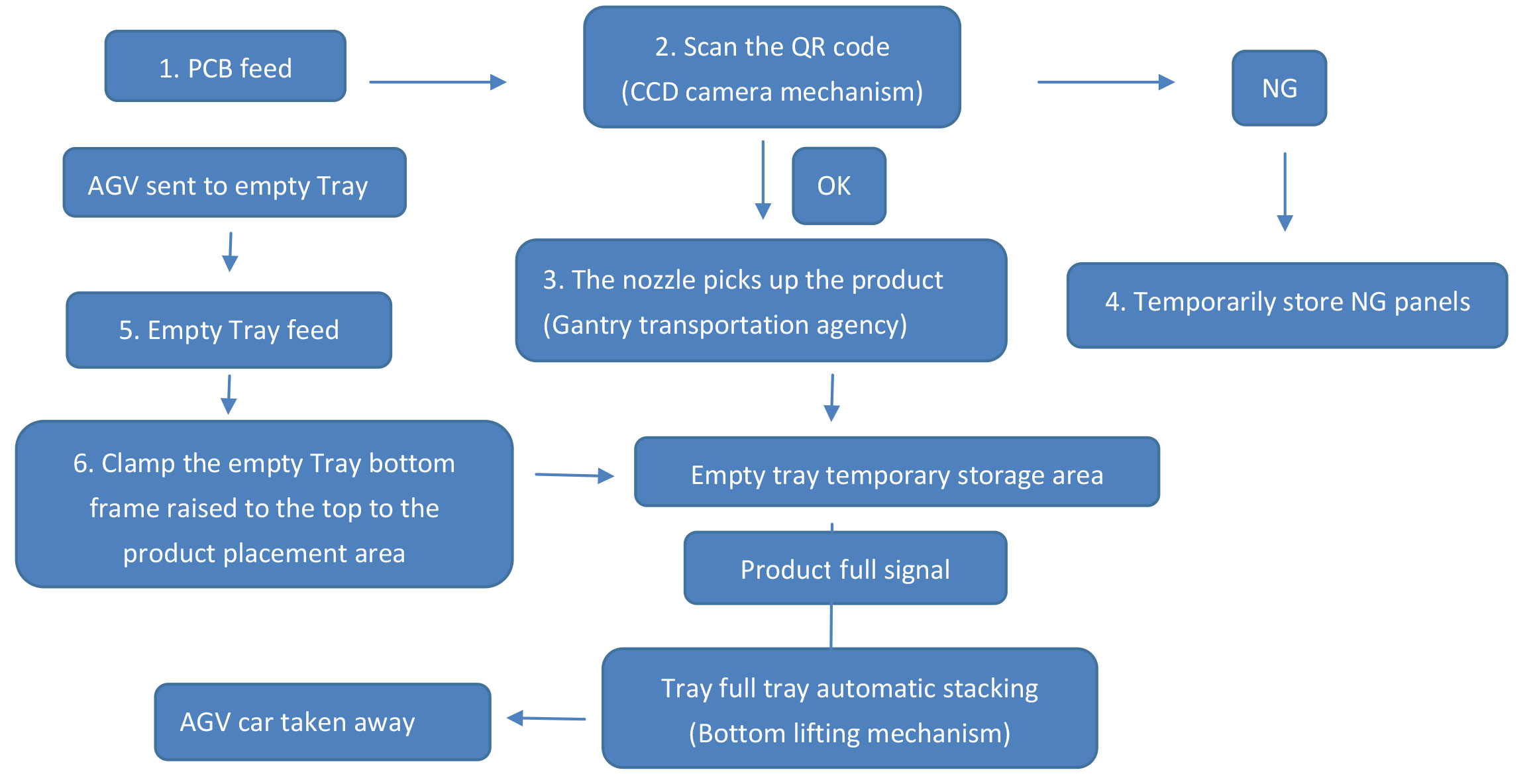

Process:

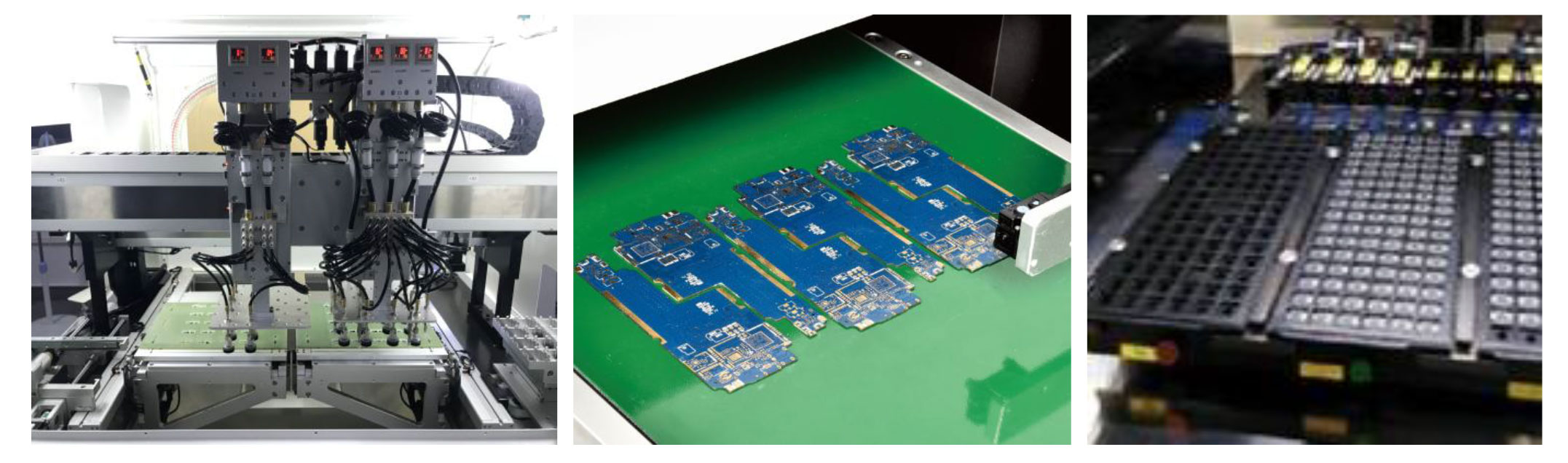

Application:

Specification:

Automatic PCBA Component Placement Machine for Semiconductor Manufacturing Workshop

| Model | I.C.T-PP3025 |

| Type | Online |

| Direction | L to R |

| Voltage | AC220V, 50/60Hz |

| Number of Nozzles | 6 |

| Pallet Quantity | 18*8PCS&19*7PCS |

| Processing Speed | 1800-2000PCS/H |

| Control Method | PC Control |

| Size | 1700 *1350 *1800 mm |

| Weight | 1500kg |

| Communication | SMEMA |

FAQ

Automatic PCBA Component Placement Machine for Semiconductor Manufacturing Workshop Automatic PCBA Component Placement Machine for Semiconductor Manufacturing Workshop Automatic PCBA Component Placement Machine for Semiconductor Manufacturing Workshop

Features:

1. Automatic feeding: auto feed the products to be placed in the plate after receiving the signal from the front machine.

2. Automatic code scanning: CCD detects the product size and has the code scanning function at the same time.

3. Automatic pan: CCD guides the suction nozzle to automatically suck OK products to pan.

4. Automatically distinguish NG code: NG products are automatically put into the NG plate, and the NG code and fork plate are put into the defective box.

5. Automatic stacking tray: automatically supply empty trays and stacking OK finished trays full trays.

6. AGV automatically feeds in empty trays and takes away full trays.

7. Adopt multi-axis bus control. 8. Production capacity: production capacity is about 1800-2000pcs/H

Structure:

Process:

Application:

Specification:

Automatic PCBA Component Placement Machine for Semiconductor Manufacturing Workshop

| Model | I.C.T-PP3025 |

| Type | Online |

| Direction | L to R |

| Voltage | AC220V, 50/60Hz |

| Number of Nozzles | 6 |

| Pallet Quantity | 18*8PCS&19*7PCS |

| Processing Speed | 1800-2000PCS/H |

| Control Method | PC Control |

| Size | 1700 *1350 *1800 mm |

| Weight | 1500kg |

| Communication | SMEMA |

FAQ

Automatic PCBA Component Placement Machine for Semiconductor Manufacturing Workshop Automatic PCBA Component Placement Machine for Semiconductor Manufacturing Workshop Automatic PCBA Component Placement Machine for Semiconductor Manufacturing Workshop

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT