ISS-2000

I.C.T

Smd Parts Storage System

| Availability: | |

|---|---|

| Quantity: | |

Smd Parts Storage System

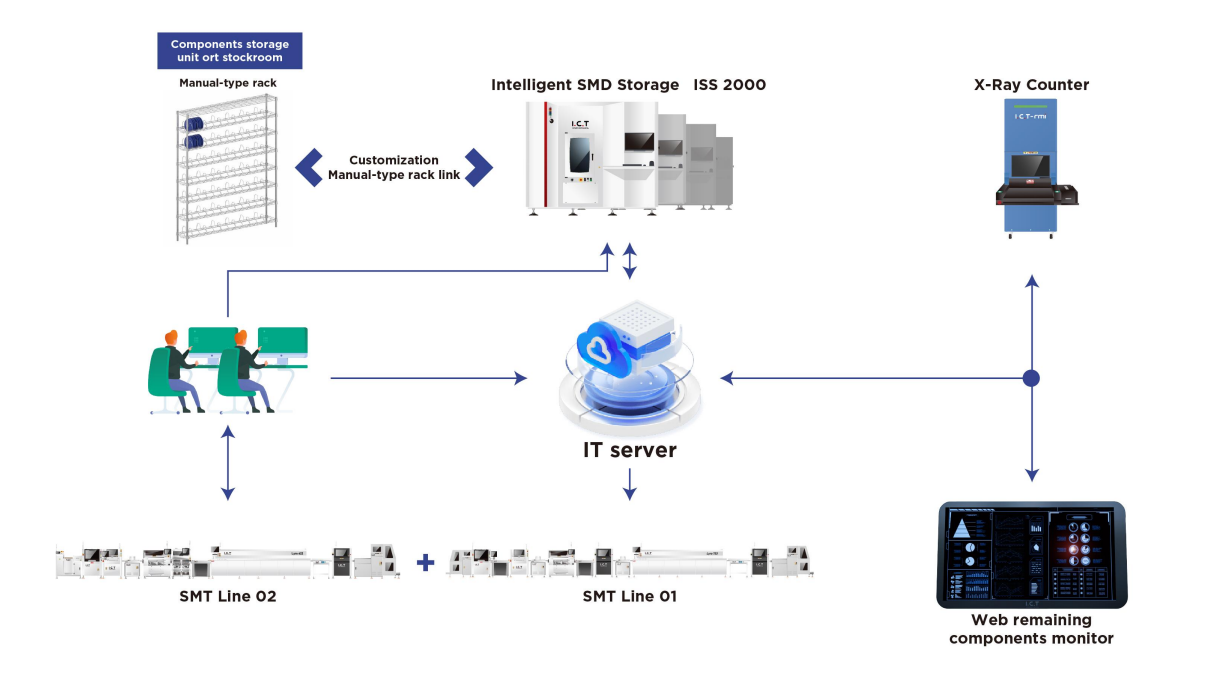

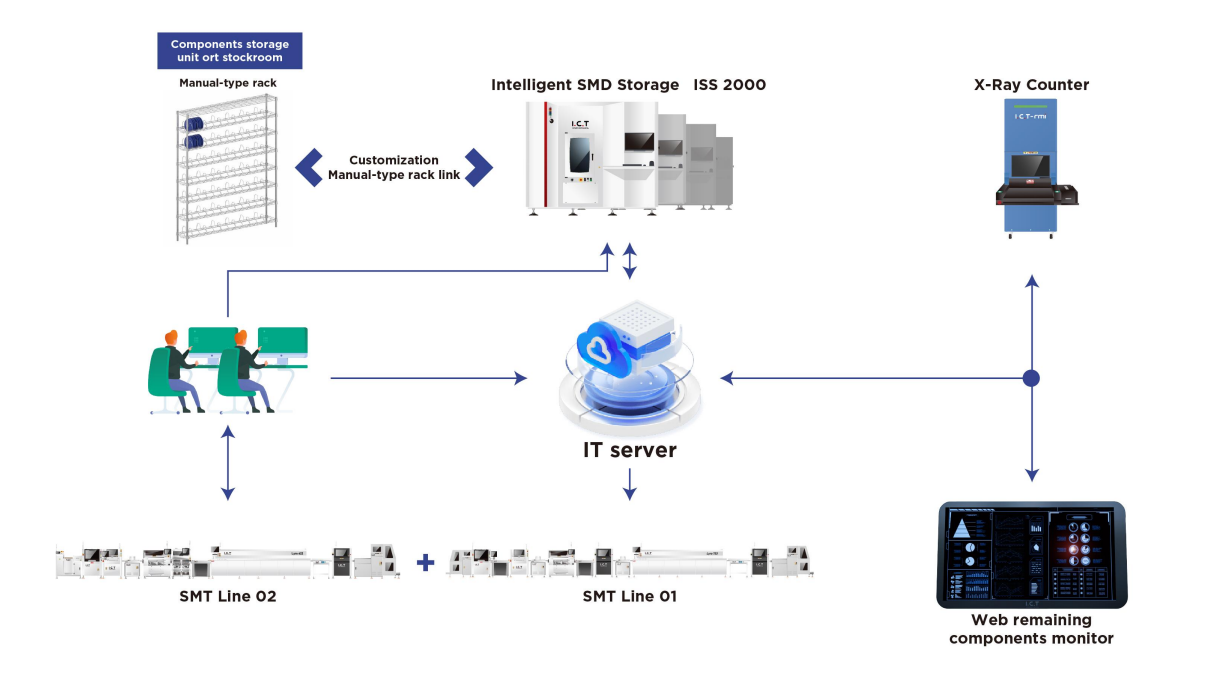

I.C.T SMT Intelligent Storage System is an important part of the smart factory.

It is a device that integrates cloud management, intelligent operation, and refined management. It performs efficient component loading/unloading and replenishment through direct processing and batch loading/unloading of reel components, reducing the cumbersome manual management. Greatly improved production efficiency.

1. Only the reels you need are unloaded.Direct handling brings a whole new level of efficiency to tasks;

2. Dedicated multifunctional unloading platform, even reels of different sizes can be unloaded;

3. Direct handling eliminates the need for dedicated storage boxes for reel assemblies and saves the space cost of dedicated storage boxes;

4. Batch Loading / Handling of up to 33 reels, compared to automatic storage that only loads 1 reel at a time, while loading or unloading components, this time can be effectively used for other tasks;

5. The Intelligent Storage System's built-in barcode reader automatically scans barcodes on all reels during batch loading. This prevents read errors caused by human error and eliminates the scanning process, making the receiving process more efficient;

6. Equipped with a temperature and humidity control module, you can choose to control the temperature and humidity inside the Intelligent Storage System 24 hours a day to avoid moisture damage to components;

7. Time limit management, managing time-limited components to avoid component defects caused by missing the use period;

8. Multiple uninstall modes, including first-in-first-out mode, prioritizing use based on production date, prioritizing uninstalling based on current use, etc;

9. "Industry 4.0": Compatible with customers' MES/ERP systems to achieve information sharing and processing.

| Model | Smd Parts Storage System | |||

| Max reel size (Depending on Configuration) | Reel height | 7” small | 13" wide | 15" Wide |

| 8mm | ok | ok | ok | |

| 12mm | ok | ok | ok | |

| 16mm | ok | ok | ok | |

| 24mm | ok | ok | ok | |

| 32mm | - | ok | ok | |

| 44mm(Option) | - | ok | ok | |

| Max reel weight | 2.0 Kg | |||

| Max reel loading/unloading at once cycle | 35 (Small Configuration) / 25 (Standard & Mixed Configuration) / 8 (Wide) | |||

| Max possible machines to connect | 99 *External server PC is required for 4 or more machines connected. | |||

| Average time for unloading | 15” seconds | |||

| Network | Ethernet LAN | |||

| Display | LCD touch screen | |||

| Operation system | Windows 10 pro | |||

| Power capacity | 1500 VA Standard with dehumidifier | |||

| Power supply | Single phase 110/230V (± 5%), 50/60Hz | |||

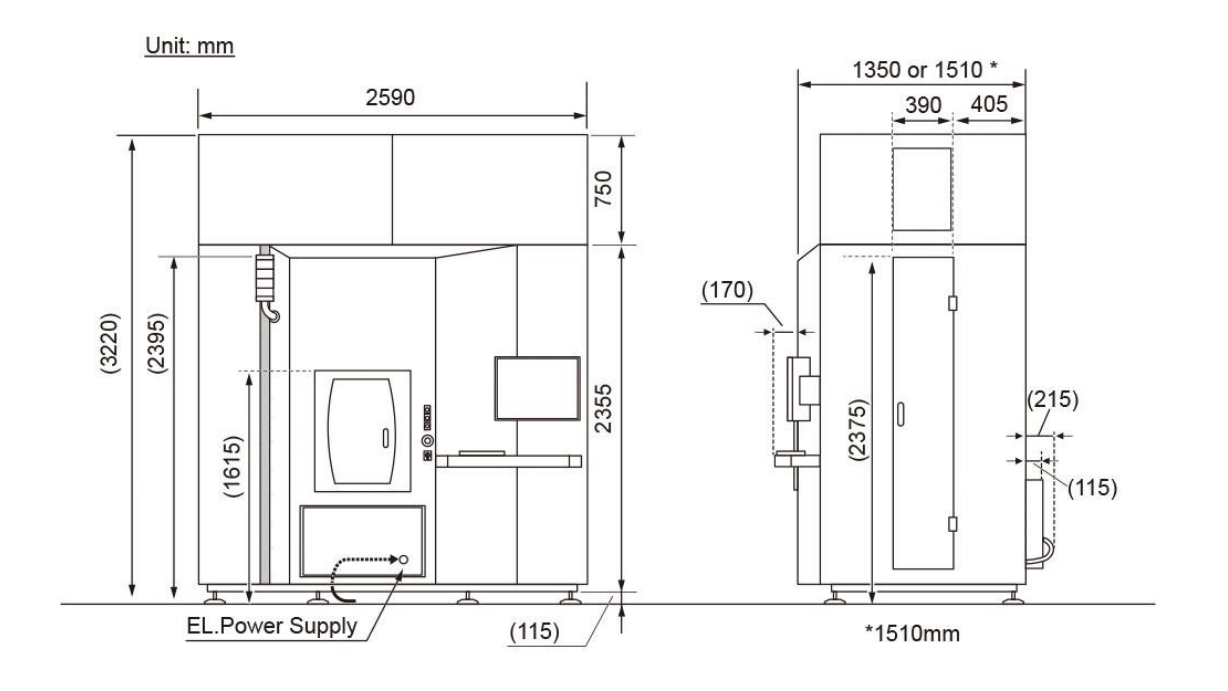

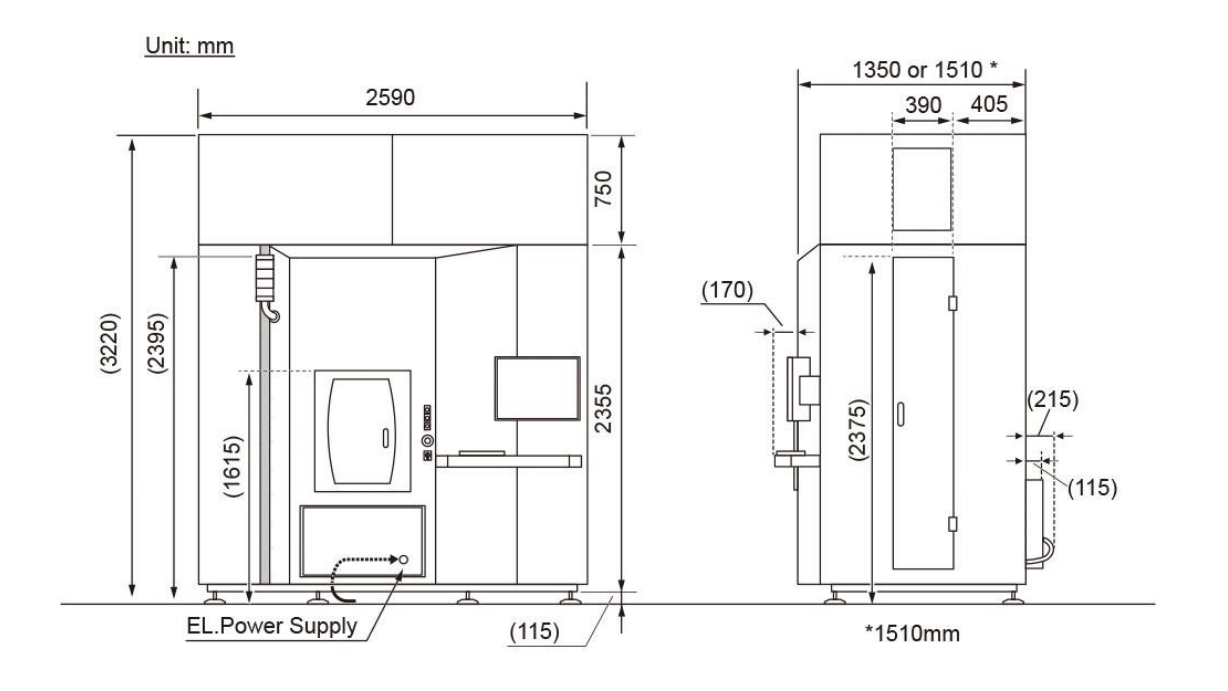

| Dimensions (Excluding tower signal) | Standard (with dehumidifiers) | 2715*1620*2450mm | ||

| With extension | 2715*1620*3200mm | |||

| Weight | Standard | 1565Kg | ||

| Extension | 417Kg | |||

* Customized mode please contact I.C.T Team.

Smd Parts Storage System

I.C.T SMT Intelligent Storage System is an important part of the smart factory.

It is a device that integrates cloud management, intelligent operation, and refined management. It performs efficient component loading/unloading and replenishment through direct processing and batch loading/unloading of reel components, reducing the cumbersome manual management. Greatly improved production efficiency.

1. Only the reels you need are unloaded.Direct handling brings a whole new level of efficiency to tasks;

2. Dedicated multifunctional unloading platform, even reels of different sizes can be unloaded;

3. Direct handling eliminates the need for dedicated storage boxes for reel assemblies and saves the space cost of dedicated storage boxes;

4. Batch Loading / Handling of up to 33 reels, compared to automatic storage that only loads 1 reel at a time, while loading or unloading components, this time can be effectively used for other tasks;

5. The Intelligent Storage System's built-in barcode reader automatically scans barcodes on all reels during batch loading. This prevents read errors caused by human error and eliminates the scanning process, making the receiving process more efficient;

6. Equipped with a temperature and humidity control module, you can choose to control the temperature and humidity inside the Intelligent Storage System 24 hours a day to avoid moisture damage to components;

7. Time limit management, managing time-limited components to avoid component defects caused by missing the use period;

8. Multiple uninstall modes, including first-in-first-out mode, prioritizing use based on production date, prioritizing uninstalling based on current use, etc;

9. "Industry 4.0": Compatible with customers' MES/ERP systems to achieve information sharing and processing.

| Model | Smd Parts Storage System | |||

| Max reel size (Depending on Configuration) | Reel height | 7” small | 13" wide | 15" Wide |

| 8mm | ok | ok | ok | |

| 12mm | ok | ok | ok | |

| 16mm | ok | ok | ok | |

| 24mm | ok | ok | ok | |

| 32mm | - | ok | ok | |

| 44mm(Option) | - | ok | ok | |

| Max reel weight | 2.0 Kg | |||

| Max reel loading/unloading at once cycle | 35 (Small Configuration) / 25 (Standard & Mixed Configuration) / 8 (Wide) | |||

| Max possible machines to connect | 99 *External server PC is required for 4 or more machines connected. | |||

| Average time for unloading | 15” seconds | |||

| Network | Ethernet LAN | |||

| Display | LCD touch screen | |||

| Operation system | Windows 10 pro | |||

| Power capacity | 1500 VA Standard with dehumidifier | |||

| Power supply | Single phase 110/230V (± 5%), 50/60Hz | |||

| Dimensions (Excluding tower signal) | Standard (with dehumidifiers) | 2715*1620*2450mm | ||

| With extension | 2715*1620*3200mm | |||

| Weight | Standard | 1565Kg | ||

| Extension | 417Kg | |||

* Customized mode please contact I.C.T Team.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

Q: What is the intelligent SMD storage system?

A: An Intelligent SMD Storage System is an automated solution designed for the storage and management of Surface Mount Device (SMD) components, commonly used in electronics manufacturing.

Q: What are the components of intelligent storage system in San?

A: Components of an intelligent storage system in SMD typically include automated storage units, robotic retrieval systems, inventory management software, barcode/RFID scanning, environmental controls, and security features.

Q: What are the benefits of intelligent SMD storage system?

A: Benefits of an Intelligent SMD Storage System encompass enhanced efficiency, reduced errors, precise inventory management, optimal space utilization, and improved traceability.

Q: What is the backend of intelligent SMD storage system?

A: The backend of an Intelligent SMD Storage System is the central computer or server that oversees software, data management, and communication with robotic systems, ensuring data security, backups, and system reliability.

Q: What is the intelligent SMD storage system?

A: An Intelligent SMD Storage System is an automated solution designed for the storage and management of Surface Mount Device (SMD) components, commonly used in electronics manufacturing.

Q: What are the components of intelligent storage system in San?

A: Components of an intelligent storage system in SMD typically include automated storage units, robotic retrieval systems, inventory management software, barcode/RFID scanning, environmental controls, and security features.

Q: What are the benefits of intelligent SMD storage system?

A: Benefits of an Intelligent SMD Storage System encompass enhanced efficiency, reduced errors, precise inventory management, optimal space utilization, and improved traceability.

Q: What is the backend of intelligent SMD storage system?

A: The backend of an Intelligent SMD Storage System is the central computer or server that oversees software, data management, and communication with robotic systems, ensuring data security, backups, and system reliability.