Views: 0 Author: Dongguan Intercontinental Technology Co.,Ltd. Publish Time: 2021-06-15 Origin: www.smtfactory.com

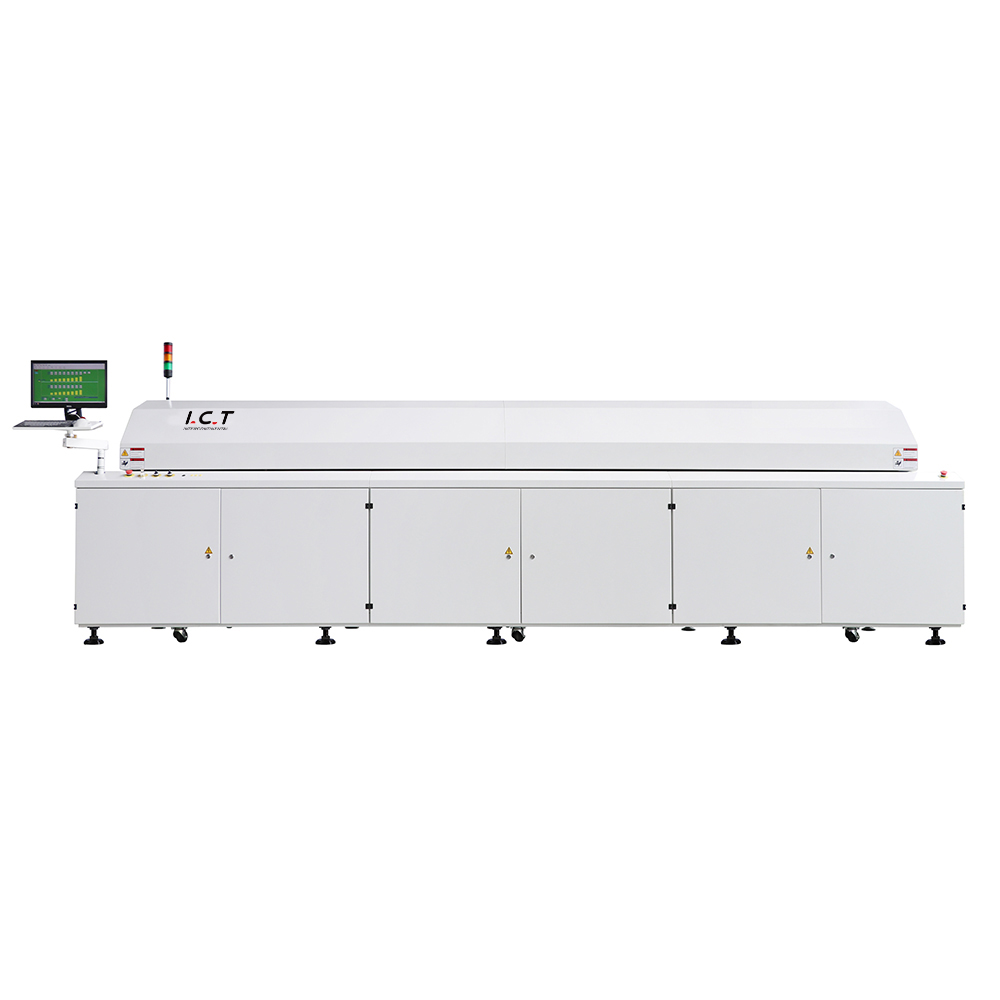

Lead-free reflow soldering is a type of Lyra Reflow Oven, and the early reflow soldering materials used lead-containing materials. With the deepening of environmental protection thinking, people pay more and more attention to lead technology. The material, especially the solder, has great changes. In terms of process, the most influential is the welding process, which is mainly caused by the characteristics of the Lyra Reflow Oven material alloy and the corresponding flux.

This is the content list:

The choice of Lyra Reflow Oven welding material is challenging

What are the methods for welding materials with Lyra Reflow Oven?

How to choose related materials and equipment after Lyra Reflow Oven welding?

In the Lyra Reflow Oven welding process, the selection of welding materials is challenging. Because for the Lyra Reflow Oven soldering process, the selection of lead-free solder, solder paste, flux and other materials is critical and difficult. When selecting these materials, the types of soldering components, the types of circuit boards, and their surface coating conditions must also be considered. The selected Lyra Reflow Oven materials should be proven in their own research, or recommended by an authority or literature, or have experience in use. List these materials in a table for testing in the process test, so as to conduct in-depth research on them and understand their impact on all aspects of the process.

For the material welding method of Lyra Reflow Oven, you should choose according to your actual situation, such as component types, surface mount components, through-hole plug-in components; the situation of the circuit board; the number and distribution of the components on the board.

For the soldering of surface mount components, Lyra Reflow Oven method is required

For through-hole plug-in components, wave soldering, dip soldering or spray soldering can be selected for soldering according to the situation.

Wave soldering is more suitable for the soldering of through-hole plug-in components on the entire board

Dip soldering is more suitable for the soldering of through-hole plug-in components on the entire board or in a local area of the board; local spray flux is more suitable for the soldering of individual components on the board or a small number of through-hole plug-in components.

The whole process of lead soldering is longer than that of leaded solder, and the required soldering temperature is higher. This is because the melting point of lead-free solder is higher than that of leaded solder, and its wettability is worse.

After the Lyra Reflow Oven welding method is selected, the type of welding process is determined. At this time, it is necessary to select equipment and related process control and process inspection equipment according to the requirements of the Lyra Reflow Oven welding process, or upgrade. The choice of Lyra Reflow Oven equipment and related equipment is the same as the selection of welding materials, and it is also very critical.