* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

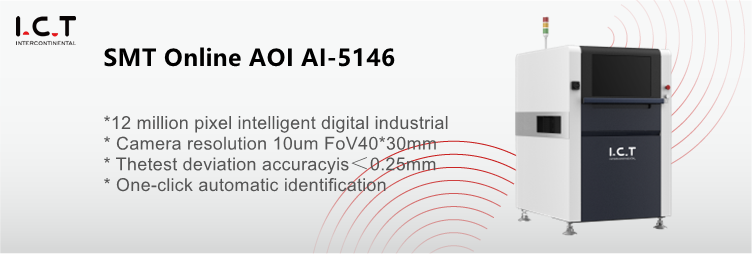

I.C.T- AI-5146

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Overview

The SMT AOI inspection systems detect a comprehensive range of defects and errors in PCB assembly, helping both to reduce your rework costs and improve your process.

Click on the right to inquire --->>

For SMT pre-reflow, post-reflow inline inspection

The I.C.T SMT Online AOI AI-5146 is an advanced inspection machine for SMT (Surface Mount Technology) production lines. It captures board images in real-time using high precision color industrial cameras and processes them with the Convolution Neural Network (CNN) algorithm to intelligently judge component and soldering defects.

Main Features and Functions of SMT Online Aoi Inspection Machine:

High Accuracy and Stability:

It offers high inspection rates with low false alarm rates, good stability ( @6 Sigma, ), and test deviation accuracy less than ±0.25mm. It also compensates for PCB warpage.

Advanced Lighting and Optics:

Features a programmable RGB + W LED lighting source and bilateral telecentric lenses with low distortion and high depth of field.

Quick Inspection Speed:

Adopts a top high - precision intelligent camera for photographing inspection, along with a deep alignment control system to maintain ultrafast moving speeds. It performs real-time computation and path planning for efficient inspection.

MES System Compatibility:

The data is retained in real-time and can be exported, with the camera able to automatically read codes (bar code and QR code). It provides complete data for process improvement and production tracing and can be effectively applied in MES systems.

Flexible Procedures

1. Intelligent judgment: Automatically check resistance, capacitance, diode and other components.

2. Offline programming: Support off-line programming. Convenient for modification and debugging.

3. Online programming: Optimize and adjust equipment parameters without stop of production line.

4. Quick changeover: Files of existing formats can be called directly without repeated adjustment.

5. Intuitively remind: SPC reminds item number, wrong device and its type with both pictures and characters.

Strong Intelligent Inspection Capability

1. Model is trained based on big data. High identification accuracy of components and soldering tin.

2. Correct alarm caused by components overhang and soldering tin deviation. Reduce false alarm. For fuzzy feature, it has strong identification capability.

3. Effectively inspect defects without being interfered by color of board and change of characters on device

4. Irregular parts inspection is strong. Automatically generate IC pin inspection checkbox. Judge multiple defects with one checkbox.

5. Strong generalization ability. Device deviation, normal through high precision identification but slight overhang of itself, slight color difference, irregular arranged devices and other complicated situation are compatible. Thus, low false alarm rate can be realized.

Multiple Inspection Modes

1. Multiple inspection modes can be designed by combining multiple production modes of factories.

2. Support multi-type machine production mode, substitute material mode and other modes.

3. Support joint-board inspection, Support mixed board inspection, Support mixed material inspection, Support multiple MARK(including Bad Mark function), Support automatic identification A/B program.

4. Multiple inspection scenarios. Support board inspection with/without fixtures.

Centralized Management and Flexible Service

1. Support remote programming, debugging and management. Save changeover time. Support one-to-many judgment.

2. Remote regulation, centralized management. Reduce suspension of work. Enhance production efficiency.

3. Remote offline programming, which will not affected inspection.

4. Remote support. Quick response and maintenance.

5. Multi-judgment work station realizes one-to-many judgment.

Specification of SMT Online AOI Inspection Machine:

| Model | I.C.T SMT AOI AI-5146 | I.C.T SMT AOI AI-5146D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 10um@40*30mm | 15um@40*30mm |

| Camera | 12M pixel intelligent digital industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4 color integral | |

| Inspection Speed | 0.23sec/FOV | |

| Inspection Algorithm | CNN, Color contrast, Outline recognition, Offset inspection, Template matching, Character comparison, OCR, etc. | |

| Inspection Item | Component: Absent, Reversed, Mis-alignment, Broken, Extra, Foreign matter, Stained, etc. Solder: Insufficient solder, excessive solder,bridging,pseudo solder etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm Right to left: max 640*460mm) | 50*50mm~510*610mm(Single rail operation) 50*50mm~510*330mm(Dual rail operation) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:80mm | Top:25mm,Bottom:30mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 750Kg | 790Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Customer Cases

Video

Watch the video to learn how automated SMT Online AOI Inspection Machine can improve efficiency in SMT manufacturing!

Click on the right to inquire --->>

Q: What types of defects can the I.C.T SMT AOI AI-5146 detect?

A: It detects soldering defects, component misalignment, polarity issues, and more.

Q: Can the SMT AOI handle dual-rail operations?

A: Yes, it supports both single and dual-rail operations with flexible configuration options.

Q: How does SMT AOI help improve the quality of SMT production?

A: AOI improves quality by using high-resolution cameras and advanced image processing to inspect components and solder joints. It identifies even the smallest defects quickly and accurately, reducing manual inspection errors. The system helps manufacturers achieve higher yields and lower defect rates by ensuring that only correctly assembled PCBs move to the next production stage.

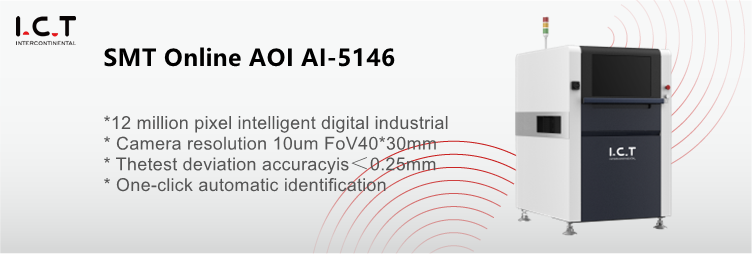

Overview

The SMT AOI inspection systems detect a comprehensive range of defects and errors in PCB assembly, helping both to reduce your rework costs and improve your process.

Click on the right to inquire --->>

For SMT pre-reflow, post-reflow inline inspection

The I.C.T SMT Online AOI AI-5146 is an advanced inspection machine for SMT (Surface Mount Technology) production lines. It captures board images in real-time using high precision color industrial cameras and processes them with the Convolution Neural Network (CNN) algorithm to intelligently judge component and soldering defects.

Main Features and Functions of SMT Online Aoi Inspection Machine:

High Accuracy and Stability:

It offers high inspection rates with low false alarm rates, good stability ( @6 Sigma, ), and test deviation accuracy less than ±0.25mm. It also compensates for PCB warpage.

Advanced Lighting and Optics:

Features a programmable RGB + W LED lighting source and bilateral telecentric lenses with low distortion and high depth of field.

Quick Inspection Speed:

Adopts a top high - precision intelligent camera for photographing inspection, along with a deep alignment control system to maintain ultrafast moving speeds. It performs real-time computation and path planning for efficient inspection.

MES System Compatibility:

The data is retained in real-time and can be exported, with the camera able to automatically read codes (bar code and QR code). It provides complete data for process improvement and production tracing and can be effectively applied in MES systems.

Flexible Procedures

1. Intelligent judgment: Automatically check resistance, capacitance, diode and other components.

2. Offline programming: Support off-line programming. Convenient for modification and debugging.

3. Online programming: Optimize and adjust equipment parameters without stop of production line.

4. Quick changeover: Files of existing formats can be called directly without repeated adjustment.

5. Intuitively remind: SPC reminds item number, wrong device and its type with both pictures and characters.

Strong Intelligent Inspection Capability

1. Model is trained based on big data. High identification accuracy of components and soldering tin.

2. Correct alarm caused by components overhang and soldering tin deviation. Reduce false alarm. For fuzzy feature, it has strong identification capability.

3. Effectively inspect defects without being interfered by color of board and change of characters on device

4. Irregular parts inspection is strong. Automatically generate IC pin inspection checkbox. Judge multiple defects with one checkbox.

5. Strong generalization ability. Device deviation, normal through high precision identification but slight overhang of itself, slight color difference, irregular arranged devices and other complicated situation are compatible. Thus, low false alarm rate can be realized.

Multiple Inspection Modes

1. Multiple inspection modes can be designed by combining multiple production modes of factories.

2. Support multi-type machine production mode, substitute material mode and other modes.

3. Support joint-board inspection, Support mixed board inspection, Support mixed material inspection, Support multiple MARK(including Bad Mark function), Support automatic identification A/B program.

4. Multiple inspection scenarios. Support board inspection with/without fixtures.

Centralized Management and Flexible Service

1. Support remote programming, debugging and management. Save changeover time. Support one-to-many judgment.

2. Remote regulation, centralized management. Reduce suspension of work. Enhance production efficiency.

3. Remote offline programming, which will not affected inspection.

4. Remote support. Quick response and maintenance.

5. Multi-judgment work station realizes one-to-many judgment.

Specification of SMT Online AOI Inspection Machine:

| Model | I.C.T SMT AOI AI-5146 | I.C.T SMT AOI AI-5146D |

| Mini Component | 01005chip,0.3pitch IC and Special shaped | |

| Resolution@FOV | 10um@40*30mm | 15um@40*30mm |

| Camera | 12M pixel intelligent digital industrial camera | |

| Lens | Telecentric lens | |

| Light | RGB+W 4 color integral | |

| Inspection Speed | 0.23sec/FOV | |

| Inspection Algorithm | CNN, Color contrast, Outline recognition, Offset inspection, Template matching, Character comparison, OCR, etc. | |

| Inspection Item | Component: Absent, Reversed, Mis-alignment, Broken, Extra, Foreign matter, Stained, etc. Solder: Insufficient solder, excessive solder,bridging,pseudo solder etc. Other: Bar code Recognition/QR code Recognition/OCR. | |

| PCB Size | 50*50mm~510*460mm (Large board mode: Left to right: max 730*460mm Right to left: max 640*460mm) | 50*50mm~510*610mm(Single rail operation) 50*50mm~510*330mm(Dual rail operation) |

| Rail | Single rail | Dual rail |

| PCB Height | Top:25mm,Bottom:80mm | Top:25mm,Bottom:30mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Edge | 3.7mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:3Kg | |

| Conveyor Height | 900±20mm | |

| With Adjustment | Manual&Auto | |

| Conveyor Direction | L ~R or R ~L | |

| Power | AC220 50/60Hz,5A | |

| Rated power | 380W | |

| Communication | SMEMA | |

| Weight | 750Kg | 790Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Customer Cases

Video

Watch the video to learn how automated SMT Online AOI Inspection Machine can improve efficiency in SMT manufacturing!

Click on the right to inquire --->>

Q: What types of defects can the I.C.T SMT AOI AI-5146 detect?

A: It detects soldering defects, component misalignment, polarity issues, and more.

Q: Can the SMT AOI handle dual-rail operations?

A: Yes, it supports both single and dual-rail operations with flexible configuration options.

Q: How does SMT AOI help improve the quality of SMT production?

A: AOI improves quality by using high-resolution cameras and advanced image processing to inspect components and solder joints. It identifies even the smallest defects quickly and accurately, reducing manual inspection errors. The system helps manufacturers achieve higher yields and lower defect rates by ensuring that only correctly assembled PCBs move to the next production stage.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT