I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Introduction:

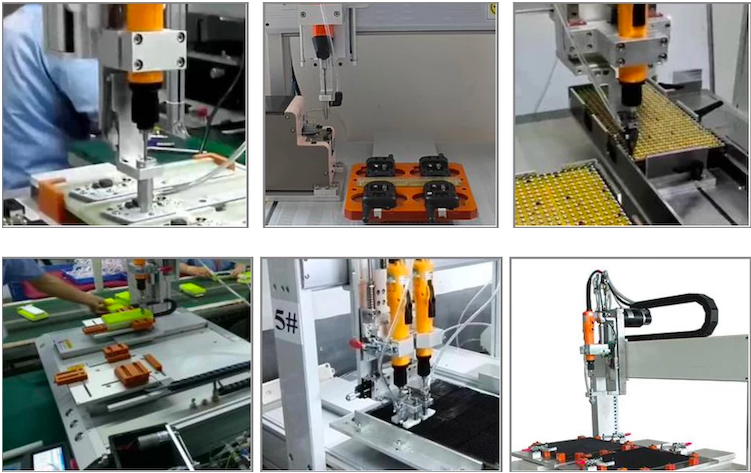

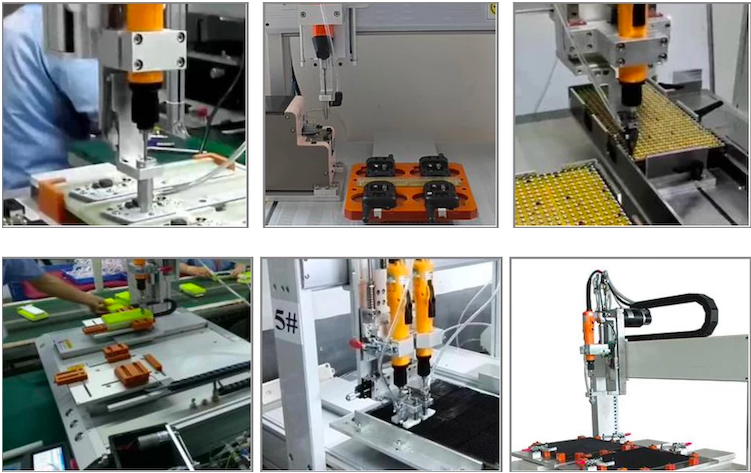

This machine include two parts: electric screwdriver and automatic screw feeder.It puts the automatic screw feeder together with the electric screwdriver in order to achieve the complement of screw transmission and fix, which can greatly improve the production efficiency and save manpower. Once the screwdriver is lifted after locking a screw, another screw will be sent continuously to continue the operation, which is particular suitable for the work piece of multi-station with the same specification.

Cost saving:High-efficiency operation is achieved by only one person. one person's efficiency amounts to 3-5 persons' efficiency.

High efficiency:the number of electric screw driver of the Z axis is customizable according to customers' requirements. Several electric screw drivers can work at the same time.

X,Y,Z,axis adopt quality step motor with it's contorl system,make machine run smoothly and precisely.

Windows7 English operation system, use touch screen with wire less controller and teach method for programming, working very easy.

Self-developed advanced software, fool-style programming with wireless controller like play game , all parameters can be set in one program.

One worker can operate 2-3 robots.what this worker does is only pick and place fixture.

Robot is strictly customized based on requirements on products,in line with requirements of production line.

More relax: single equipment for single worker, Just finished loading,Reduce the labor intensity of workers.

Reliability: Automatic alarm system, working >20 hours.

Iintelligent automatic equipment presents a new appearance of production line in factories.

Customization: Robot can be customized based on customers' requirements on products assembly.

| Model | I.C.T-SCR300 | I.C.T-SCR540 | I.C.T-SCR640 |

Max. Range Size: | 300*300mm, Z:80mm | 500*400mm, Z:80mm | 600*400mm, Z:80mm |

Head Number: | 1 | 1 | 2 |

Platform Number: | 1 | 2 | 2 |

Screw driver: | SD /KILEWS/HIOS | ||

Screw Feeding: | Pick and Place,Magnetic | ||

Programming: | Traction Teaching Program | ||

Driving Mode: | Closed-loop Motor | ||

Control Mode: | Microcontroller+Touch Panel | ||

Dimension(mm): | 670*540*690 | 670*590*690 | 1010*730*690 |

Weight: | Approx:70kg | Approx:90kg | Approx:130kg |

Introduction:

This machine include two parts: electric screwdriver and automatic screw feeder.It puts the automatic screw feeder together with the electric screwdriver in order to achieve the complement of screw transmission and fix, which can greatly improve the production efficiency and save manpower. Once the screwdriver is lifted after locking a screw, another screw will be sent continuously to continue the operation, which is particular suitable for the work piece of multi-station with the same specification.

Cost saving:High-efficiency operation is achieved by only one person. one person's efficiency amounts to 3-5 persons' efficiency.

High efficiency:the number of electric screw driver of the Z axis is customizable according to customers' requirements. Several electric screw drivers can work at the same time.

X,Y,Z,axis adopt quality step motor with it's contorl system,make machine run smoothly and precisely.

Windows7 English operation system, use touch screen with wire less controller and teach method for programming, working very easy.

Self-developed advanced software, fool-style programming with wireless controller like play game , all parameters can be set in one program.

One worker can operate 2-3 robots.what this worker does is only pick and place fixture.

Robot is strictly customized based on requirements on products,in line with requirements of production line.

More relax: single equipment for single worker, Just finished loading,Reduce the labor intensity of workers.

Reliability: Automatic alarm system, working >20 hours.

Iintelligent automatic equipment presents a new appearance of production line in factories.

Customization: Robot can be customized based on customers' requirements on products assembly.

| Model | I.C.T-SCR300 | I.C.T-SCR540 | I.C.T-SCR640 |

Max. Range Size: | 300*300mm, Z:80mm | 500*400mm, Z:80mm | 600*400mm, Z:80mm |

Head Number: | 1 | 1 | 2 |

Platform Number: | 1 | 2 | 2 |

Screw driver: | SD /KILEWS/HIOS | ||

Screw Feeding: | Pick and Place,Magnetic | ||

Programming: | Traction Teaching Program | ||

Driving Mode: | Closed-loop Motor | ||

Control Mode: | Microcontroller+Touch Panel | ||

Dimension(mm): | 670*540*690 | 670*590*690 | 1010*730*690 |

Weight: | Approx:70kg | Approx:90kg | Approx:130kg |

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

Successful Experience:

I.C.T's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

Successful Experience:

I.C.T's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT