I.C.T-S400

I.C.T

spi machine

| Availability: | |

|---|---|

| Quantity: | |

I.C.T 3D SPI can completely solve the problem of shadow and random reflection in the detection process, so that solder paste 3D detection accuracy is higher; equipped with a 5M pixel high-speed camera, detection speed is faster, the image is more delicate and rich; it is an ideal choice for high-speed and high-precision production lines.

* PCB Size: 55*55~460*460mm

* Camera Pixel: 5M, (10M/12M as option)

* Standard SPC

* Standard Automatic Conveyor Adjustment

* Cycle Time:0.35~0.5s/FOV

Features of 3D SPI SMT Solder Paste Inspection Machine:

1. The lens of professional lens design makes the image more uniform and delicate, and greatly improves the stability of detection.

2. It can be imported into Gerber file programming, or can be used to edit and debug money from image editing mode.

3.The multi direction 3D projection method can effectively solve the detection error caused by the shadow effect in the solder paste

detection process.

4.The operation system improves the result recognition and processing function according to the user level interface structure.

5. High precision programmable black and white moire fringe, the highest measuring accuracy 0.67um.

6.Based on accurate 3 dimensional measurement data, operators can optimize the whole project in a short time.

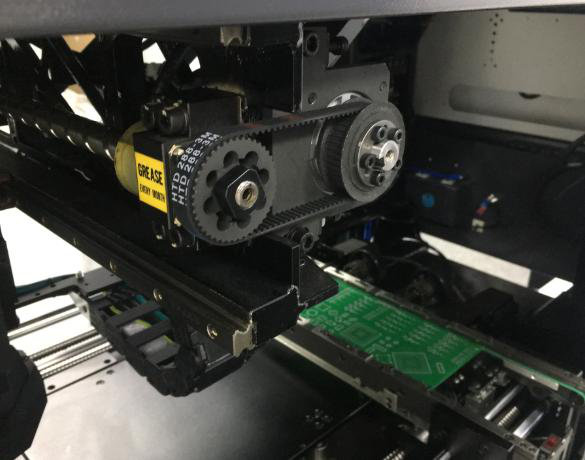

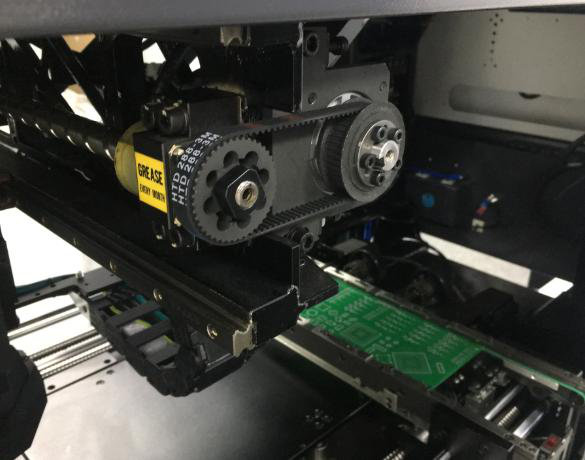

3D Technology

High precision programmable black and white moire fringe. High precision light source control technology, multiple multiple exposures. The highest measuring accuracy 0.67um.

The fringe rays are projected and collected, and multiple images are taken at one time for comprehensive calculation.

Strobe, constant light, instant exposure,Multiple exposure, 10 channelsHigh precision light source control.

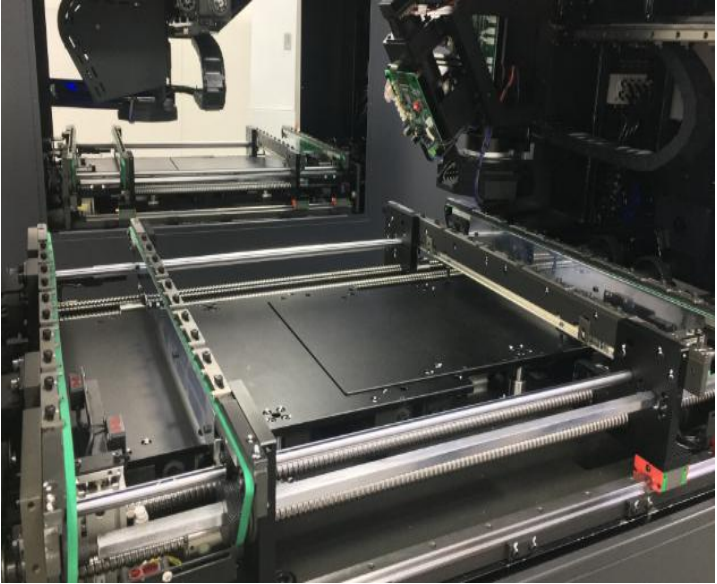

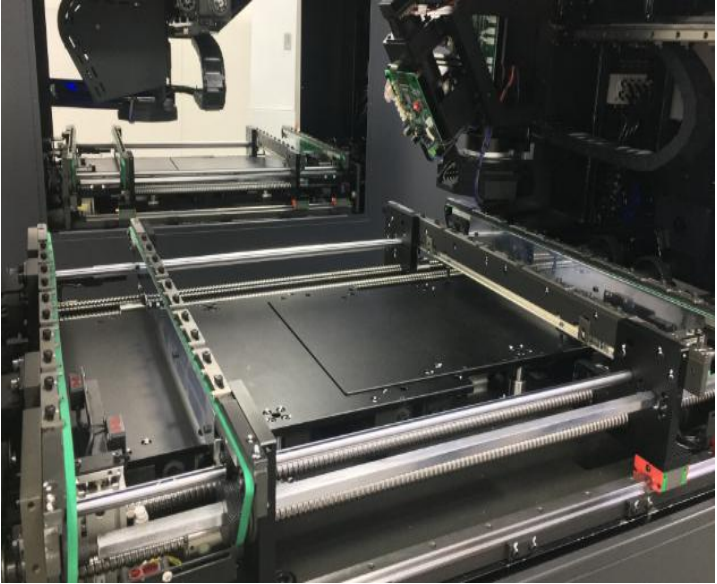

Compact structure, minimum footprint, monorail dual rail

PCB optional.

Integral casting structure, FPC compatible, PCB can be up to 1200 * 500mm.

Specification of 3D SPI SMT Solder Paste Inspection Machine:

| Model | I.C.T-S400 | I.C.T-S400D | I.C.T-S1200 |

| PCB Size | 55*55 ~460*460mm (470*500mm as option) (630*686mm as option) | 55*55 ~450*310mm Dual (470*310mm Dual as option) (630*310mm Dual as option) | 55*55 ~ 1200*650mm |

| PCB Tickness | 0.5 ~ 7.0mm | ||

| PCB Weight | ≤5.0kg | ||

| Conveyor Adjustment | Automatic | ||

| Measure Type | Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination) | ||

| Paste Height | 0 ~ 550um | ||

| Min Pad Pitch | ≥100um | ||

| Measure Principle | 3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase Measurement Profilometry) | ||

| Inspection Head Quantity | 1 | ||

| Camera Pixel | 5M, (10M/12M as option) | ||

| Detection Speed | 0.35 ~ 0.5s/FOV | ||

| Program Time | 5 ~ 10min | ||

| Data Type | Gerber Data 274D/274X, Scan PCB | ||

| Power | AC220,50/60Hz,1KVA | ||

| Machine Dimension | 1000*1150*1530mm | 1000*1350*1530mm | 1730*1420*1530mm |

| Weight | 965kg | 1200kg | 1600kg |

* I.C.T keeps working on quality and performance,specifications and appearance may be updated without particular notice.

I.C.T 3D SPI can completely solve the problem of shadow and random reflection in the detection process, so that solder paste 3D detection accuracy is higher; equipped with a 5M pixel high-speed camera, detection speed is faster, the image is more delicate and rich; it is an ideal choice for high-speed and high-precision production lines.

* PCB Size: 55*55~460*460mm

* Camera Pixel: 5M, (10M/12M as option)

* Standard SPC

* Standard Automatic Conveyor Adjustment

* Cycle Time:0.35~0.5s/FOV

Features of 3D SPI SMT Solder Paste Inspection Machine:

1. The lens of professional lens design makes the image more uniform and delicate, and greatly improves the stability of detection.

2. It can be imported into Gerber file programming, or can be used to edit and debug money from image editing mode.

3.The multi direction 3D projection method can effectively solve the detection error caused by the shadow effect in the solder paste

detection process.

4.The operation system improves the result recognition and processing function according to the user level interface structure.

5. High precision programmable black and white moire fringe, the highest measuring accuracy 0.67um.

6.Based on accurate 3 dimensional measurement data, operators can optimize the whole project in a short time.

3D Technology

High precision programmable black and white moire fringe. High precision light source control technology, multiple multiple exposures. The highest measuring accuracy 0.67um.

The fringe rays are projected and collected, and multiple images are taken at one time for comprehensive calculation.

Strobe, constant light, instant exposure,Multiple exposure, 10 channelsHigh precision light source control.

Compact structure, minimum footprint, monorail dual rail

PCB optional.

Integral casting structure, FPC compatible, PCB can be up to 1200 * 500mm.

Specification of 3D SPI SMT Solder Paste Inspection Machine:

| Model | I.C.T-S400 | I.C.T-S400D | I.C.T-S1200 |

| PCB Size | 55*55 ~460*460mm (470*500mm as option) (630*686mm as option) | 55*55 ~450*310mm Dual (470*310mm Dual as option) (630*310mm Dual as option) | 55*55 ~ 1200*650mm |

| PCB Tickness | 0.5 ~ 7.0mm | ||

| PCB Weight | ≤5.0kg | ||

| Conveyor Adjustment | Automatic | ||

| Measure Type | Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient tin, excessive tin, bridging, offset, mal-shapes, surface contamination) | ||

| Paste Height | 0 ~ 550um | ||

| Min Pad Pitch | ≥100um | ||

| Measure Principle | 3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase Measurement Profilometry) | ||

| Inspection Head Quantity | 1 | ||

| Camera Pixel | 5M, (10M/12M as option) | ||

| Detection Speed | 0.35 ~ 0.5s/FOV | ||

| Program Time | 5 ~ 10min | ||

| Data Type | Gerber Data 274D/274X, Scan PCB | ||

| Power | AC220,50/60Hz,1KVA | ||

| Machine Dimension | 1000*1150*1530mm | 1000*1350*1530mm | 1730*1420*1530mm |

| Weight | 965kg | 1200kg | 1600kg |

* I.C.T keeps working on quality and performance,specifications and appearance may be updated without particular notice.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT