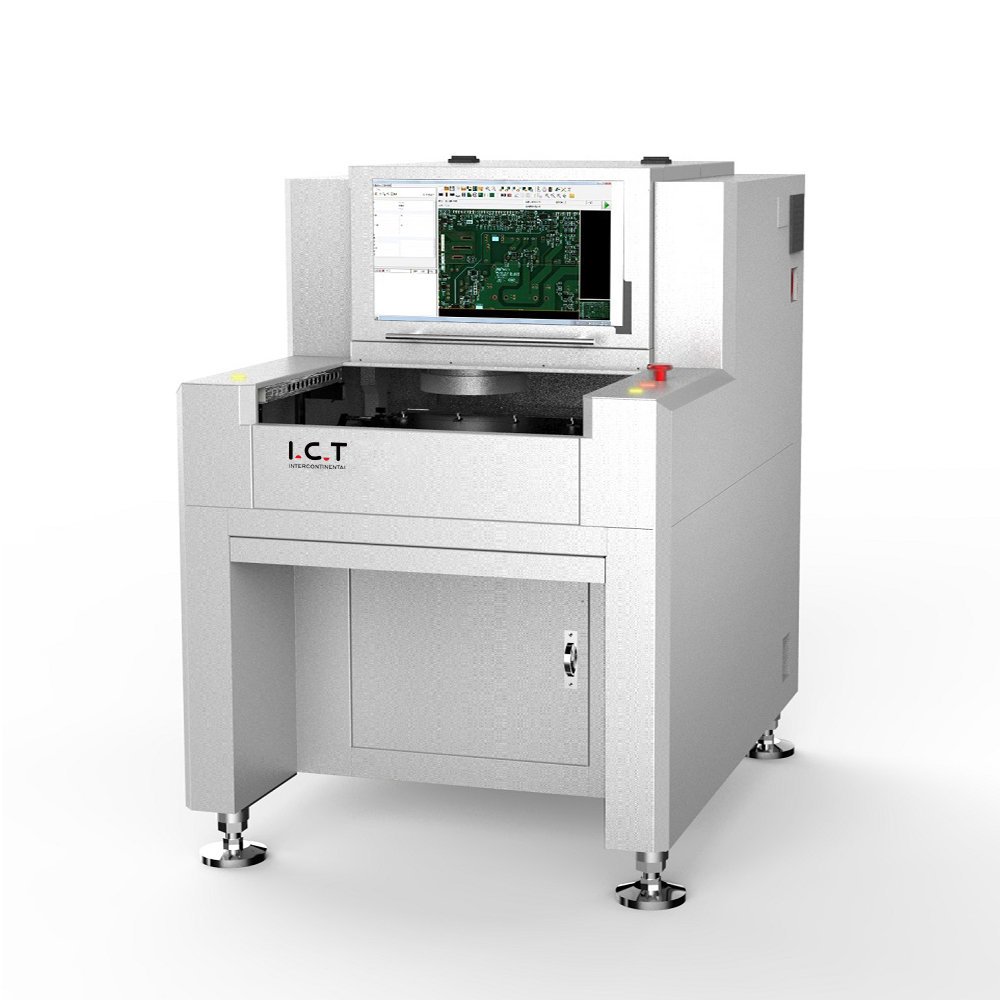

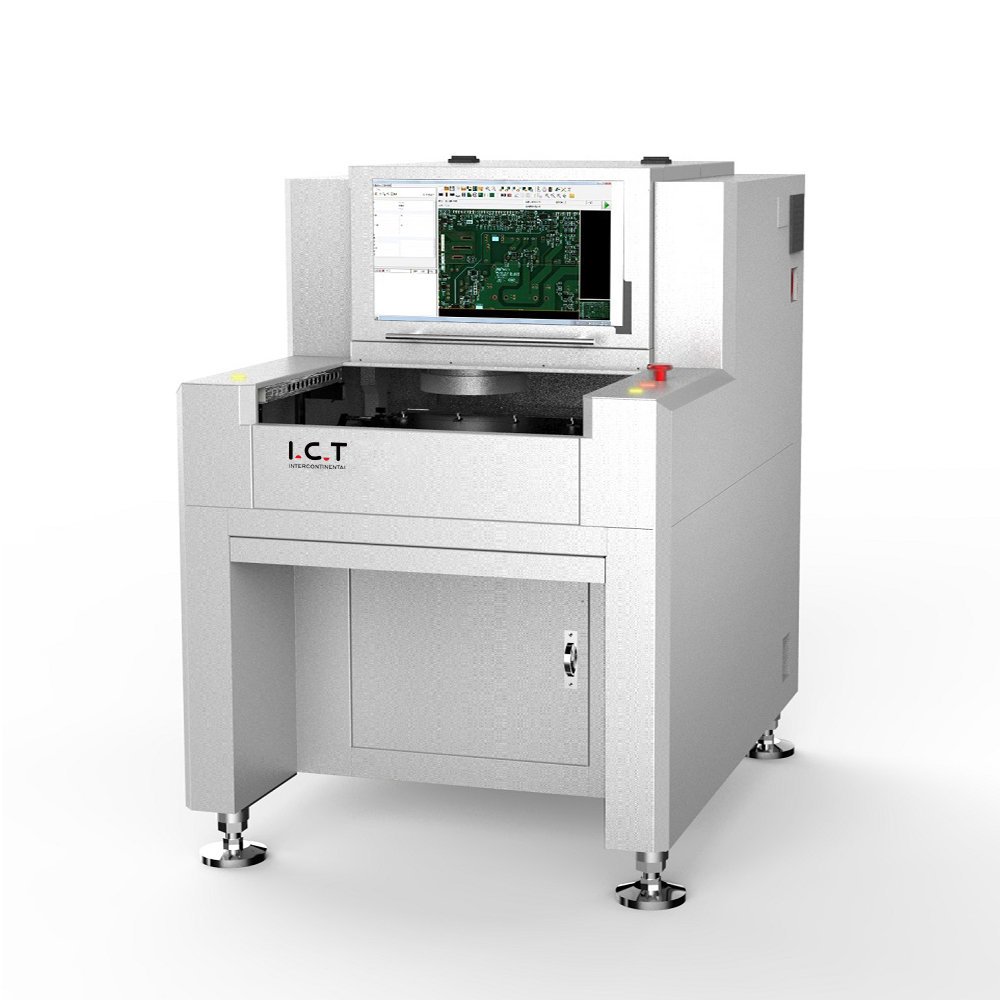

I.C.T-V8

I.C.T

aoi inspection

| Availability: | |

|---|---|

| Quantity: | |

Off Line AOI V8

Introduction:

For SMT pre-reflow, post-reflow inline inspection.

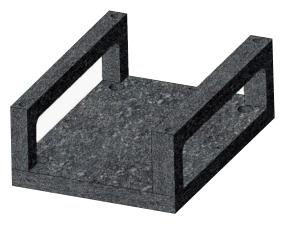

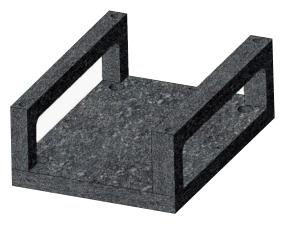

Granite platform, greatly improve machine precision and stability.

Programmable RGB+W LED lighting source.

Telecentric lens with constant magnification and low distortion response to high compone.

Features:

1. LOG automatic collecting and storage function,NG warning/alarm function, Remote programming&debugging.

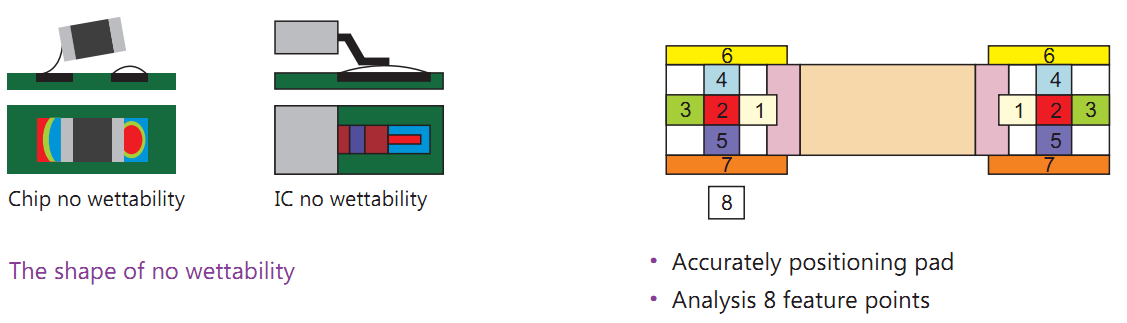

2. Inspection ability:insufficient,short,slodering hole,solder covering pin,contamination,misalignment,missing part,skewed,billboard,mounting

on side,overturn,wrong part,damaged,float,polarity,pseudo soldering,empty solder,excessive glue etc.

3. Perfect SPC collects NG information off line and generates all kinds of production tables automatically.

4. Mature control center function,clear software interface.

5. Good stability(GR&R<10% @6 Sigma,CPK>1.33(Test deviation accuracy less than ±0.25mm.

6. Camera move,conveyor fixed during test.

7. PCB warpage conpensation:total Mark compensation calibration,conponent position frame compensation.

Granite Platform and Frame

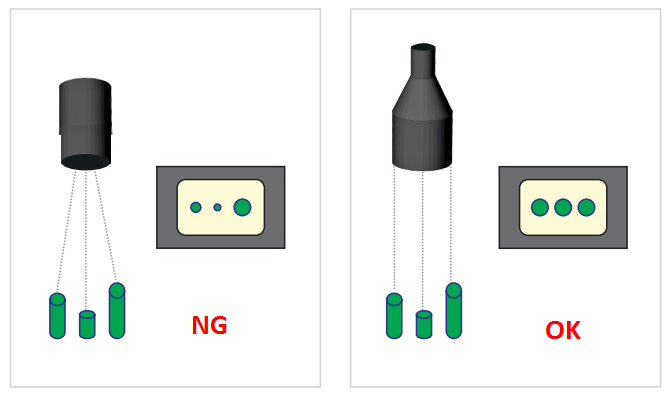

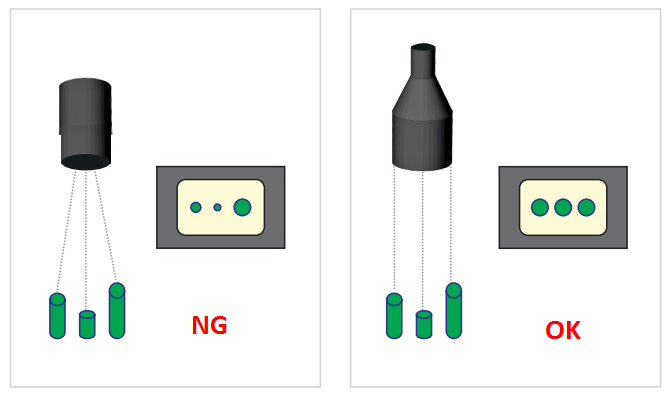

Industrial camera+Telecentric lens

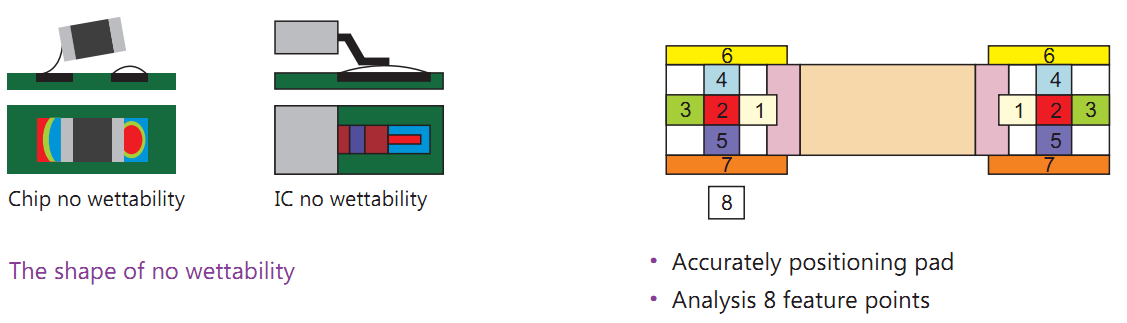

Entire FOV Assist Position

| Model | I.C.T-V8 | I.C.T-V8XL |

| FOV | 15u(38.4*28.8mm) | |

| Camera | 5M pixel intelligent digital industrial camera | |

| Lens | Telecentric lens | |

| Light | 4 color ring LED light,RGB+W | |

| Inspection Item | Component test,soldering test | |

| Mini Component | 03015chip,0.3pitch IC and Special shaped | |

| Operation System | Windows 7 | |

| PCB Size | 50*50~430*330mm | 50*50~650*510mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| PCB Height | Top:25-60mm,Bottom:25-80mm adjustable | |

| X/Y Driver | AC servo driver,repeat accuracy 0.01mm | |

| Platform | Granite | |

| Power | AC220 50/60Hz,2.5A | |

| Communication | SMEMA | |

| Weight | 500Kg | 600Kg |

| Dimension | 880*1170*1350mm(excluding the light) | 1080*1470*1370mm(excluding the light) |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Off Line AOI V8

Introduction:

For SMT pre-reflow, post-reflow inline inspection.

Granite platform, greatly improve machine precision and stability.

Programmable RGB+W LED lighting source.

Telecentric lens with constant magnification and low distortion response to high compone.

Features:

1. LOG automatic collecting and storage function,NG warning/alarm function, Remote programming&debugging.

2. Inspection ability:insufficient,short,slodering hole,solder covering pin,contamination,misalignment,missing part,skewed,billboard,mounting

on side,overturn,wrong part,damaged,float,polarity,pseudo soldering,empty solder,excessive glue etc.

3. Perfect SPC collects NG information off line and generates all kinds of production tables automatically.

4. Mature control center function,clear software interface.

5. Good stability(GR&R<10% @6 Sigma,CPK>1.33(Test deviation accuracy less than ±0.25mm.

6. Camera move,conveyor fixed during test.

7. PCB warpage conpensation:total Mark compensation calibration,conponent position frame compensation.

Granite Platform and Frame

Industrial camera+Telecentric lens

Entire FOV Assist Position

| Model | I.C.T-V8 | I.C.T-V8XL |

| FOV | 15u(38.4*28.8mm) | |

| Camera | 5M pixel intelligent digital industrial camera | |

| Lens | Telecentric lens | |

| Light | 4 color ring LED light,RGB+W | |

| Inspection Item | Component test,soldering test | |

| Mini Component | 03015chip,0.3pitch IC and Special shaped | |

| Operation System | Windows 7 | |

| PCB Size | 50*50~430*330mm | 50*50~650*510mm |

| PCB Thickness | 0.3 ~ 6.0mm | |

| PCB Warpage | ±3.0mm | |

| PCB Weight | Max:10Kg | |

| PCB Height | Top:25-60mm,Bottom:25-80mm adjustable | |

| X/Y Driver | AC servo driver,repeat accuracy 0.01mm | |

| Platform | Granite | |

| Power | AC220 50/60Hz,2.5A | |

| Communication | SMEMA | |

| Weight | 500Kg | 600Kg |

| Dimension | 880*1170*1350mm(excluding the light) | 1080*1470*1370mm(excluding the light) |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

Packing Method:

Standard Wooden Case With Vacuum Package

Shipping Way:

1. By air, for sample and small package,international express like DHL, UPS, EMS...

2. By sea, for large package and quantity;

3. Other ways as customer requested.

Delivery Time:

25-35 Days

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

Packing Method:

Standard Wooden Case With Vacuum Package

Shipping Way:

1. By air, for sample and small package,international express like DHL, UPS, EMS...

2. By sea, for large package and quantity;

3. Other ways as customer requested.

Delivery Time:

25-35 Days

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT