I.C.T DIP Production Line

I.C.T

DIP Production Line

| Availability: | |

|---|---|

| Quantity: | |

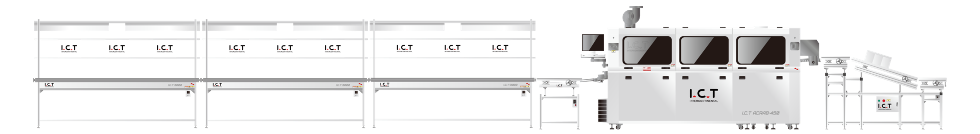

3m Insertion Line * 3 → Wave Loader → Wave Soldering Machine → Wave Unloader

Manufacturing high-quality printed circuit boards (PCBs) involves intensive processes such as rigorous inspection, rework, mounting, and selective soldering. To address these challenges, I.C.T offer the Fully Automatic DIP production Line. This system is engineered to minimize costs, enhance accuracy and productivity, and streamline your PCB manufacturing and inspection operations from start to finish.

DIP Insertion Line (Manual&Automatic)

DIP Insertion Line (Manual&Automatic) Manual or automated equipment inserts components into pre-drilled holes on the PCB. A standard DIP production line typically features three 3-meter-long insertion lines, ensuring efficient and precise component placement.

* One or both sides alongside the conveyor.

* Taiwan Motor-driven chain

* Standard length is 3 meter, with one workstation per meter, totaling three workstations.

* 40w lighting, lamp by FSL, Wire is 1.5², Subsection control.

PCB Wave Loader

The Wave Loader is responsible for automatically transferring the PCB board with inserted components to the wave soldering machine. It reduces manual operation and improves production efficiency.

* Automated PCB board loading, reducing manual operation.

* Precise docking wave soldering process.

* Improve production efficiency.

Wave Soldering Machine and Selective Wave Soldering Machine

Wave soldering is one of the core equipment of DIP production line. Wave soldering makes the component pins firmly connected to the pad on the PCB by passing the PCB board through the melted solder crest. This process is very important because it can handle multiple solder joints at the same time, ensuring the quality and consistency of the soldering.

In addition to traditional wave soldering, a DIP production line may also include selective wave soldering. This process is primarily used for components or parts that need to avoid direct contact with the wave, such as components already mounted using Surface Mount Technology (SMT), like QFN packaged chips.

In a DIP production line, selective wave soldering complements traditional wave soldering by providing flexibility to meet diverse PCB assembly requirements.

PCB Wave Unloader

After the soldering is completed, the PCB is received by the wave soldering machine and transferred to the next process. This ensures that the welded PCB board can be safely and quickly moved to the next step for subsequent assembly or testing.

FAQ : DIP Production Line

Q: What we can do for you?

A: Total SMT Machines and SMT/ DIP/ Coating Solution, professional Technical Support and Service.

Q: Are you a trade company or a manufacturer?

A: OEM & ODM service are available.

Q: What is your delivery date?

A: The delivery date is about 45 days after receipt of payment, the specific time depends on the order.

Q: Why choose us?

A: Leading SMT Supplier in China; Trade assurance to USD 560,000+; Professional after-sales service team.

Q: Do you provide after-sales service?

A: I.C.T provide a comprehensive after-sales service, including installation, commissioning, training and maintenance support.

Q: Can the equipment be customized?

A: Yes, I.C.T can provide customized equipment configuration according to your specific needs.

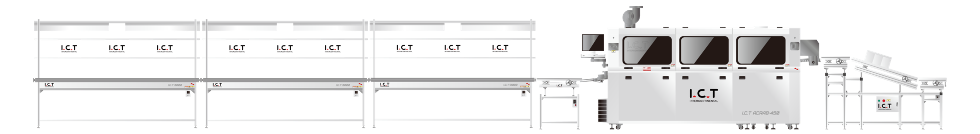

3m Insertion Line * 3 → Wave Loader → Wave Soldering Machine → Wave Unloader

Manufacturing high-quality printed circuit boards (PCBs) involves intensive processes such as rigorous inspection, rework, mounting, and selective soldering. To address these challenges, I.C.T offer the Fully Automatic DIP production Line. This system is engineered to minimize costs, enhance accuracy and productivity, and streamline your PCB manufacturing and inspection operations from start to finish.

DIP Insertion Line (Manual&Automatic)

DIP Insertion Line (Manual&Automatic) Manual or automated equipment inserts components into pre-drilled holes on the PCB. A standard DIP production line typically features three 3-meter-long insertion lines, ensuring efficient and precise component placement.

* One or both sides alongside the conveyor.

* Taiwan Motor-driven chain

* Standard length is 3 meter, with one workstation per meter, totaling three workstations.

* 40w lighting, lamp by FSL, Wire is 1.5², Subsection control.

PCB Wave Loader

The Wave Loader is responsible for automatically transferring the PCB board with inserted components to the wave soldering machine. It reduces manual operation and improves production efficiency.

* Automated PCB board loading, reducing manual operation.

* Precise docking wave soldering process.

* Improve production efficiency.

Wave Soldering Machine and Selective Wave Soldering Machine

Wave soldering is one of the core equipment of DIP production line. Wave soldering makes the component pins firmly connected to the pad on the PCB by passing the PCB board through the melted solder crest. This process is very important because it can handle multiple solder joints at the same time, ensuring the quality and consistency of the soldering.

In addition to traditional wave soldering, a DIP production line may also include selective wave soldering. This process is primarily used for components or parts that need to avoid direct contact with the wave, such as components already mounted using Surface Mount Technology (SMT), like QFN packaged chips.

In a DIP production line, selective wave soldering complements traditional wave soldering by providing flexibility to meet diverse PCB assembly requirements.

PCB Wave Unloader

After the soldering is completed, the PCB is received by the wave soldering machine and transferred to the next process. This ensures that the welded PCB board can be safely and quickly moved to the next step for subsequent assembly or testing.

FAQ : DIP Production Line

Q: What we can do for you?

A: Total SMT Machines and SMT/ DIP/ Coating Solution, professional Technical Support and Service.

Q: Are you a trade company or a manufacturer?

A: OEM & ODM service are available.

Q: What is your delivery date?

A: The delivery date is about 45 days after receipt of payment, the specific time depends on the order.

Q: Why choose us?

A: Leading SMT Supplier in China; Trade assurance to USD 560,000+; Professional after-sales service team.

Q: Do you provide after-sales service?

A: I.C.T provide a comprehensive after-sales service, including installation, commissioning, training and maintenance support.

Q: Can the equipment be customized?

A: Yes, I.C.T can provide customized equipment configuration according to your specific needs.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT