I.C.T-Lyra622/622N

I.C.T

Reflow Oven 8 Zone

| Availability: | |

|---|---|

| Quantity: | |

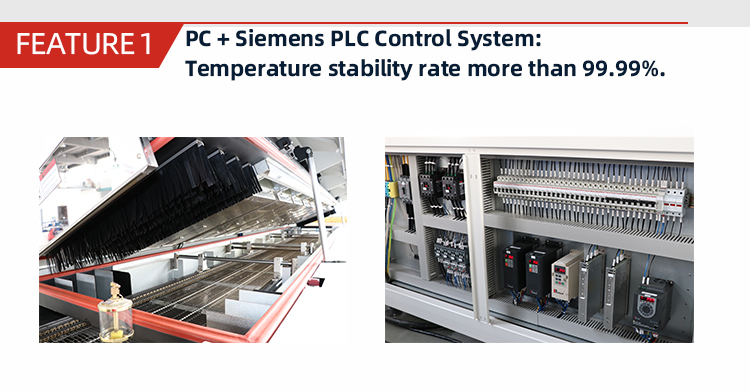

I.C.T Lyra series lead-free reflow oven I.C.T’s mature product after years of market testing. Lyra Series Reflow oven has maintained a larger share of the market for many years. Its unparalleled heating performance and temperature control system meets the requirements of various soldering processes, It is I.C.T’s crystallization of years technical research and development.

Lyra Series Lead-free reflow is high-end reflow products committed to keeping up with market demand to enhance customers competitiveness.Its new design concept fully meets the needs of increasingly diverse processes, And considering the future direction of the industry, entirely suitable for communications, automotive electronics, home appliances, computers and other consumer electronic products.

Reflow Oven 8 Zone

Lyra Series Reflow Oven 8 Zone

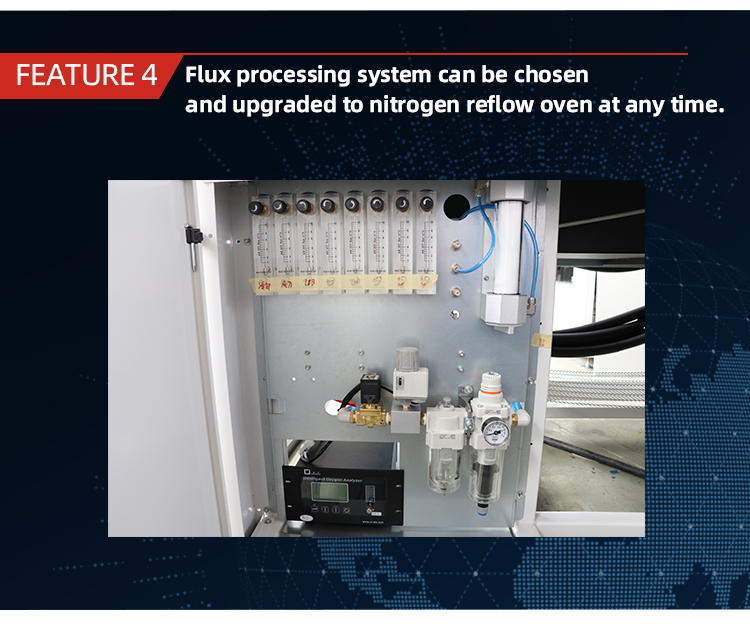

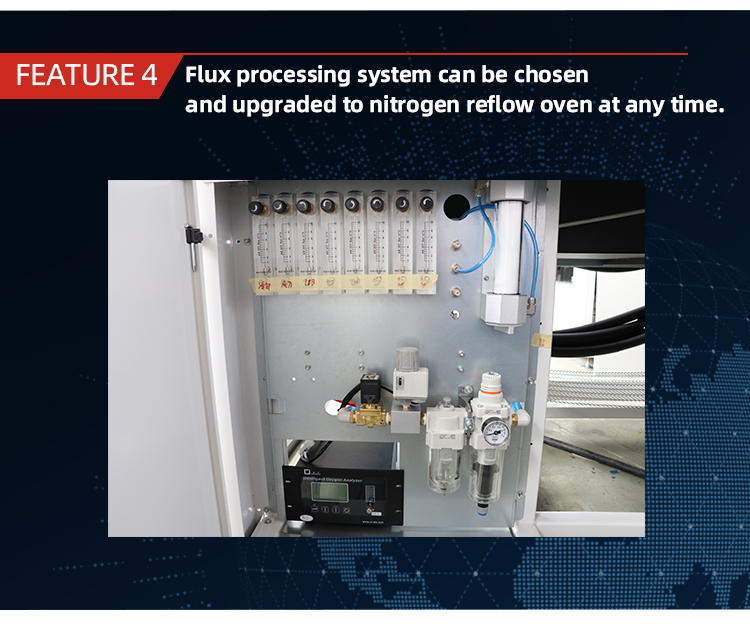

High effective flux management system

High stability nitrogen protection system

High performance cooling system

Support the CBS, Split Unit

| Model | Lyra 622/622N | Lyra 733/733N | Lyra 933/ 933N |

| Quantity of preheating zones | 6 | 7 | 9 |

| Quantity of peak zones | 2 | 3 | 3 |

| Max. soldering temperature | pre-heating zones 300 °C and peak zones350 °C | ||

| Quantity of cooling zones | 2 | 2 | 3 |

| Mesh Width | Standard 440mm( Option 560 & 680mm ) | ||

| Rail Width | Single Rail: 50 - 460mm, Option: 50 - 686mm other Width on request. Dual Rail Standard: 50 - 290mm*2 | ||

| Dimensions | 5150*1400*1500mm | 6250*1400*1500mm | 6950*1400*1500mm |

| Weight | 2400 / 2600 kg | 2800 / 3000 kg | 3200 /3400 kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T Lyra series lead-free reflow oven I.C.T’s mature product after years of market testing. Lyra Series Reflow oven has maintained a larger share of the market for many years. Its unparalleled heating performance and temperature control system meets the requirements of various soldering processes, It is I.C.T’s crystallization of years technical research and development.

Lyra Series Lead-free reflow is high-end reflow products committed to keeping up with market demand to enhance customers competitiveness.Its new design concept fully meets the needs of increasingly diverse processes, And considering the future direction of the industry, entirely suitable for communications, automotive electronics, home appliances, computers and other consumer electronic products.

Reflow Oven 8 Zone

Lyra Series Reflow Oven 8 Zone

High effective flux management system

High stability nitrogen protection system

High performance cooling system

Support the CBS, Split Unit

| Model | Lyra 622/622N | Lyra 733/733N | Lyra 933/ 933N |

| Quantity of preheating zones | 6 | 7 | 9 |

| Quantity of peak zones | 2 | 3 | 3 |

| Max. soldering temperature | pre-heating zones 300 °C and peak zones350 °C | ||

| Quantity of cooling zones | 2 | 2 | 3 |

| Mesh Width | Standard 440mm( Option 560 & 680mm ) | ||

| Rail Width | Single Rail: 50 - 460mm, Option: 50 - 686mm other Width on request. Dual Rail Standard: 50 - 290mm*2 | ||

| Dimensions | 5150*1400*1500mm | 6250*1400*1500mm | 6950*1400*1500mm |

| Weight | 2400 / 2600 kg | 2800 / 3000 kg | 3200 /3400 kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Question: What is an 8-zone reflow oven?

Answer: An 8-zone reflow oven is a specialized piece of equipment used in Surface Mount Technology (SMT) manufacturing, featuring eight distinct temperature-controlled zones. These zones allow for precise management of the heating and cooling processes required for soldering components onto printed circuit boards (PCBs). The 8-zone configuration provides enhanced control over the soldering profile, ensuring high-quality and reliable solder joints for complex and densely populated PCBs.

Question: How does an 8-zone reflow oven improve the soldering process?

Answer: An 8-zone reflow oven improves the soldering process by offering detailed control over each stage of the temperature profile. Here's how it benefits the process:

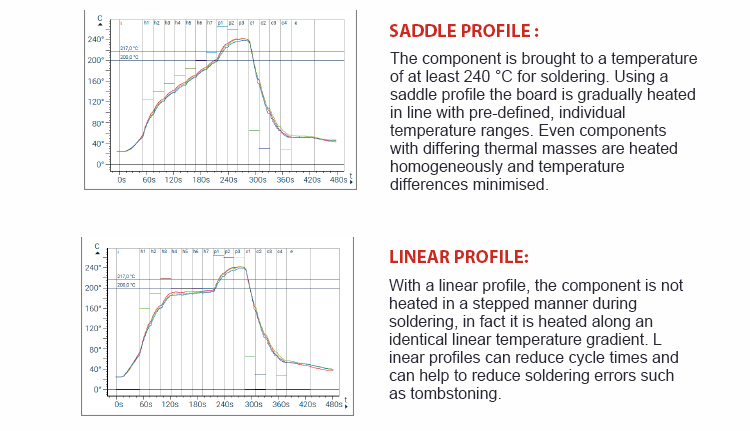

Preheat Zones: Gradually increase the temperature to safely bring PCBs up to the necessary heat levels without causing thermal shock.

Soak Zones: Maintain a stable temperature to activate flux and ensure even heating across all components.

Reflow Zones: Precisely control the peak temperature to melt solder paste and form strong, reliable solder joints.

Cooling Zones: Carefully reduce the temperature to solidify the solder without causing thermal stress or defects. This multi-zone control results in superior solder quality, reduced defects, and better overall reliability of the electronic assemblies.

Question: What are the benefits of using an 8-zone reflow oven in electronics manufacturing?

Answer: Using an 8-zone reflow oven in electronics manufacturing offers several significant benefits:

Enhanced Precision: Provides detailed temperature control, ensuring consistent and high-quality solder joints.

Improved Throughput: Allows for faster processing of PCBs, increasing production efficiency and capacity.

Superior Quality: Reduces the risk of defects such as cold joints, bridging, and tombstoning, enhancing the reliability of electronic products.

Flexibility: Capable of handling a wide range of PCB sizes and component densities, making it ideal for complex and high-density assemblies.

Energy Efficiency: Optimizes energy usage by precisely controlling heating elements, reducing overall operating costs.

Question: What is an 8-zone reflow oven?

Answer: An 8-zone reflow oven is a specialized piece of equipment used in Surface Mount Technology (SMT) manufacturing, featuring eight distinct temperature-controlled zones. These zones allow for precise management of the heating and cooling processes required for soldering components onto printed circuit boards (PCBs). The 8-zone configuration provides enhanced control over the soldering profile, ensuring high-quality and reliable solder joints for complex and densely populated PCBs.

Question: How does an 8-zone reflow oven improve the soldering process?

Answer: An 8-zone reflow oven improves the soldering process by offering detailed control over each stage of the temperature profile. Here's how it benefits the process:

Preheat Zones: Gradually increase the temperature to safely bring PCBs up to the necessary heat levels without causing thermal shock.

Soak Zones: Maintain a stable temperature to activate flux and ensure even heating across all components.

Reflow Zones: Precisely control the peak temperature to melt solder paste and form strong, reliable solder joints.

Cooling Zones: Carefully reduce the temperature to solidify the solder without causing thermal stress or defects. This multi-zone control results in superior solder quality, reduced defects, and better overall reliability of the electronic assemblies.

Question: What are the benefits of using an 8-zone reflow oven in electronics manufacturing?

Answer: Using an 8-zone reflow oven in electronics manufacturing offers several significant benefits:

Enhanced Precision: Provides detailed temperature control, ensuring consistent and high-quality solder joints.

Improved Throughput: Allows for faster processing of PCBs, increasing production efficiency and capacity.

Superior Quality: Reduces the risk of defects such as cold joints, bridging, and tombstoning, enhancing the reliability of electronic products.

Flexibility: Capable of handling a wide range of PCB sizes and component densities, making it ideal for complex and high-density assemblies.

Energy Efficiency: Optimizes energy usage by precisely controlling heating elements, reducing overall operating costs.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT