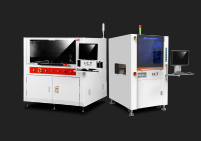

It boasts the highest 105,000CPH in its class*, and is equipped with ultra-high speed, space-saving features, while boasting high area productivity and achieving highly efficient production.

The Planet P20S head supports mounting of 0201 very small parts.

In addition, even large components and other highly versatile design heads can be equipped with ultra-high speed 94,000CPH that are among the highest in their class.

English

English