I.C.T-AISM08

I.C.T

SMT Tape Automatic Splice Station

| Availability: | |

|---|---|

| Quantity: | |

Introduce:

I.C.T SMT Automatic Splicing Machine is developed to meet the requirements of SMT automatic production line for fast refueling without shutdown.

It can automatically detect the position of empty component, accurately cut and over probability of more than 98% for the head and tail of two rolls of material belts with the same specification.

It can be equipped with RC measurement function to reduce dependence on manpower, reduce management cost, improve detection efficiency, improve the production rate of SMT production line and avoid batch misfeeding, I.C.T smt splicing machine has completed the full coverage of 4-72mm feeder.

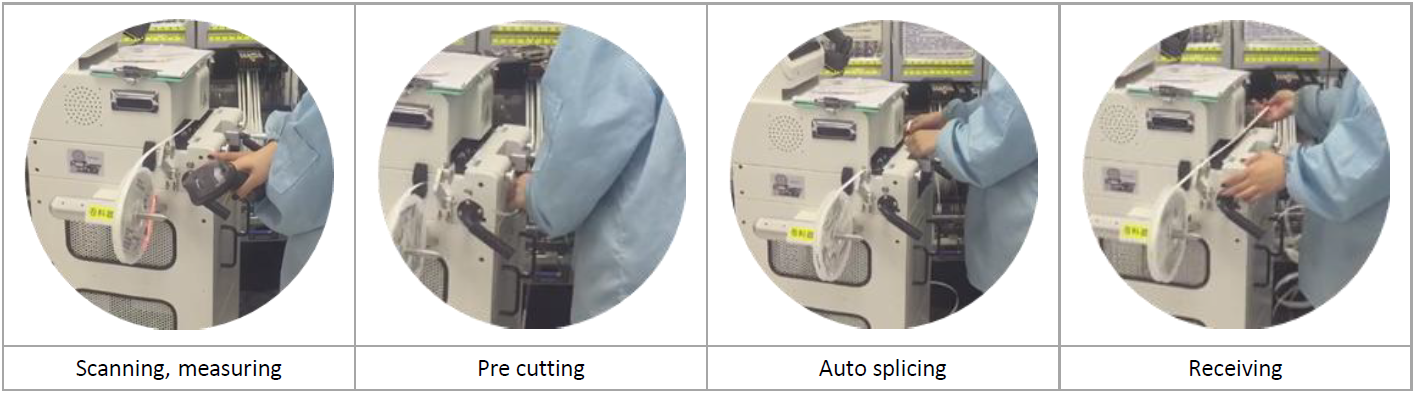

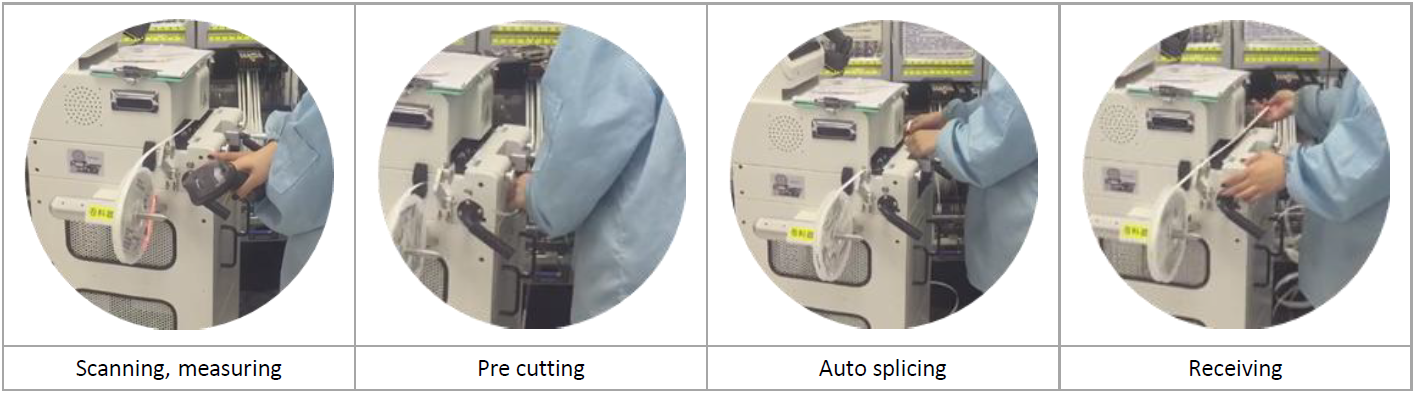

Process: SMT Tape Automatic Splice Station

1.Simple operation: learn to operate in 5 minutes, everyone can operate, and reduce dependence on personnel.

2.Error proofing: automatic code scanning and error proofing, which can be connected with the customer's MES for double foolproof.

3.Empty components detection: CCD detection can identify the above 01005 .

4.Accurate traceability: connect MES production system to facilitate customer traceability.

5.Increase the production line production rate: increase the production line production rate of SMT with a probability of more than 95%.

6.Determination of measured value: RC measured value function can be selected to avoid batch wrong components.

7. Labor saving: one person operation realize two smt lines.

8. Determination of empty components level and spacing: use CCD optics to automatically detect the presence or absence of components, and

automatically and accurately calibrate the cutting position of components.

9. Recycling: after the components is received successfully, the operator will press the components reel recycling button for a long time to

realize automatic material collection, which is convenient and fast.

10. Accurate and efficient: each time only about 10s to complete.

Operating system

Touch screen operation, simple operation, 5 minutes to learn to

operate, barrier free, Chinese and English optional.

CCD system

Empty components detection: CCD detection can identify the above

01005, and the docking accuracy is ± 0.08.

Splicing system

Stepper motor drive, special gear structure. accurate, patented

structure design, success rate 98%.

Feeding system

Mold manufacturing, more than 2000 machines are verified in

the customer's factory, with perfect stability.

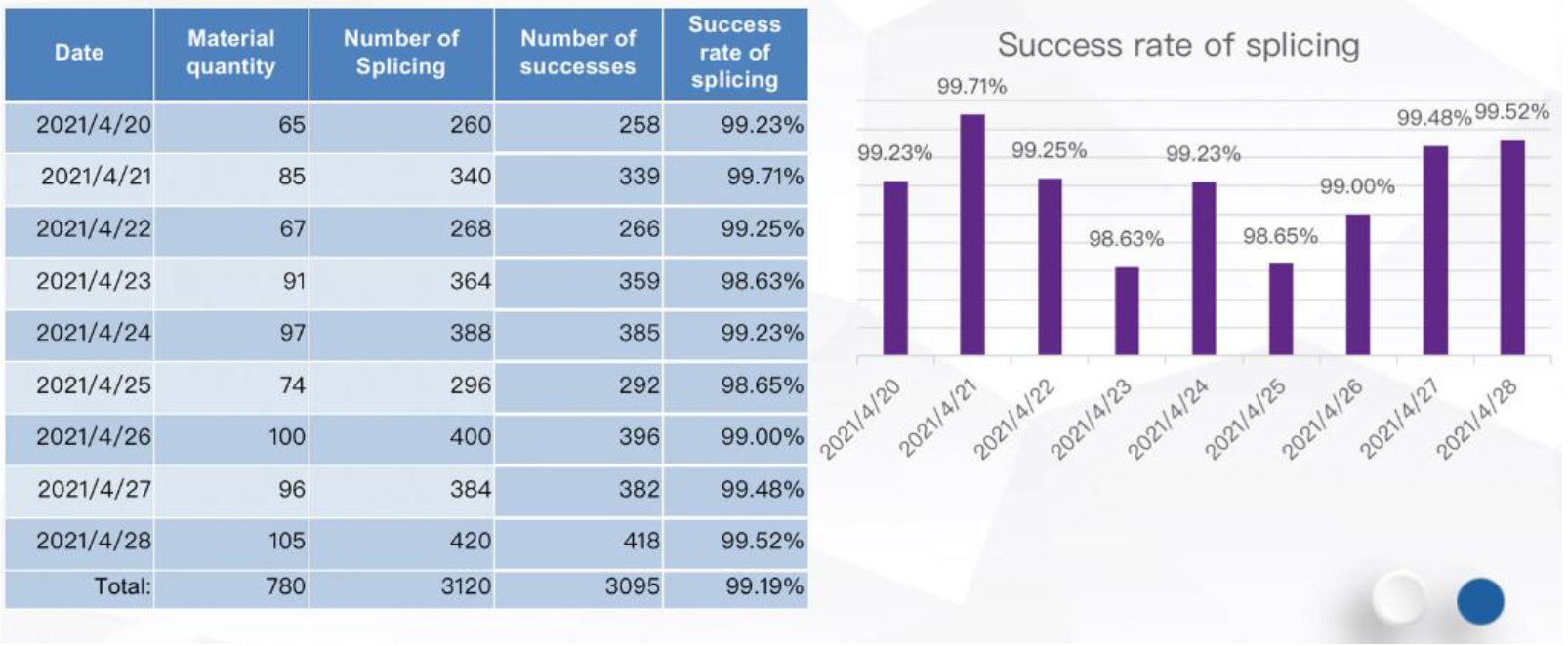

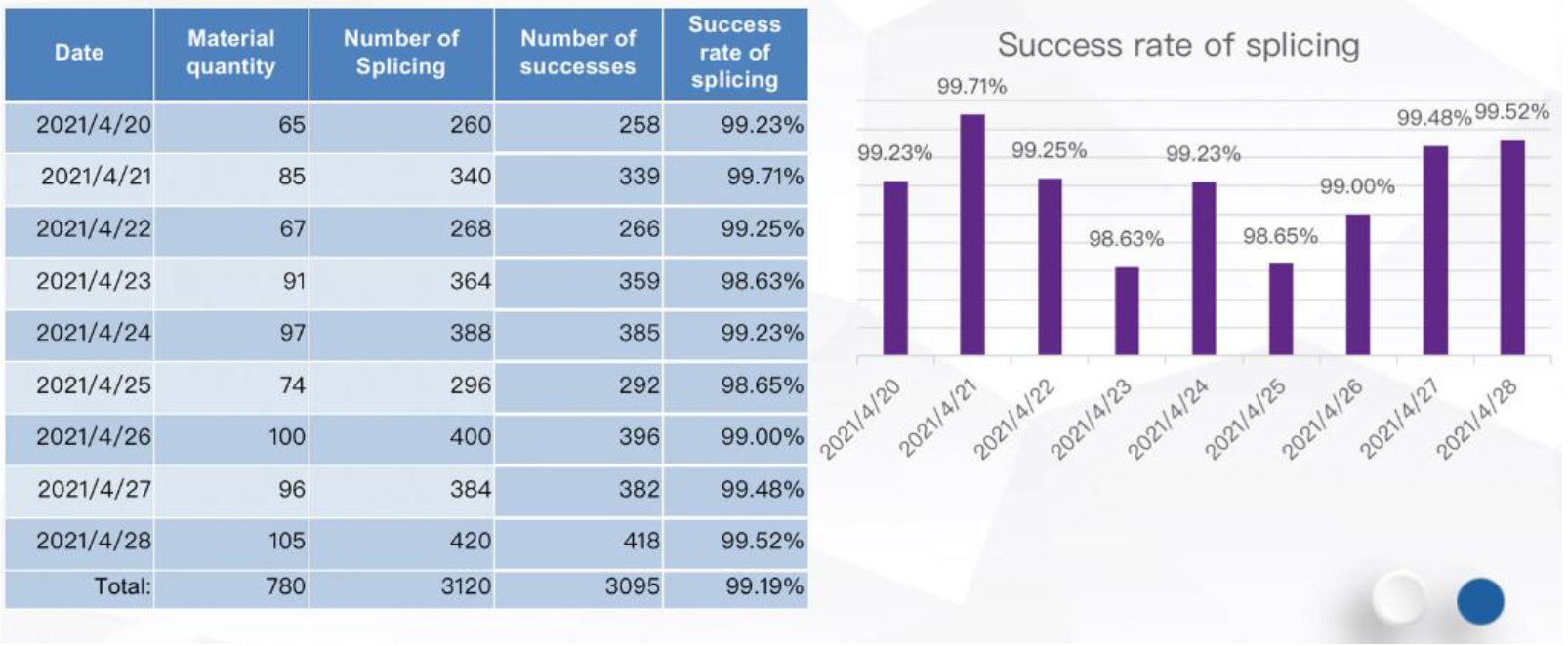

Success rate of splicing: 99.19%

| SMT Tape Automatic Splice Station | |||

| Mode | I.C.T-ASM08 | I.C.T-AISM08 | I.C.T-AISM16 |

| Applicable Mounter | Full SMT brand | ||

| Splicing Mode | Auto cutting and Splicing | ||

| Splicing Tape Size | 32mm | 32mm | 32mm*2 |

| Splicing Tape Package | Reel | ||

| Splicing Cycle Time | 6-12sec (excluding manual operation and empty tape detection time) | ||

| Passing rate on Mounter | 95% | 98% | 98% |

| Dimension / mm | 550*470*1300 | 400*470*1400 | 360*310*1320 |

| Weight | Approx: 65KG | Approx: 65KG | Approx: 70KG |

* The data is obtained under ambient temperature of 25℃ and humidity of 60%.

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

FAQ:

Introduce:

I.C.T SMT Automatic Splicing Machine is developed to meet the requirements of SMT automatic production line for fast refueling without shutdown.

It can automatically detect the position of empty component, accurately cut and over probability of more than 98% for the head and tail of two rolls of material belts with the same specification.

It can be equipped with RC measurement function to reduce dependence on manpower, reduce management cost, improve detection efficiency, improve the production rate of SMT production line and avoid batch misfeeding, I.C.T smt splicing machine has completed the full coverage of 4-72mm feeder.

Process: SMT Tape Automatic Splice Station

1.Simple operation: learn to operate in 5 minutes, everyone can operate, and reduce dependence on personnel.

2.Error proofing: automatic code scanning and error proofing, which can be connected with the customer's MES for double foolproof.

3.Empty components detection: CCD detection can identify the above 01005 .

4.Accurate traceability: connect MES production system to facilitate customer traceability.

5.Increase the production line production rate: increase the production line production rate of SMT with a probability of more than 95%.

6.Determination of measured value: RC measured value function can be selected to avoid batch wrong components.

7. Labor saving: one person operation realize two smt lines.

8. Determination of empty components level and spacing: use CCD optics to automatically detect the presence or absence of components, and

automatically and accurately calibrate the cutting position of components.

9. Recycling: after the components is received successfully, the operator will press the components reel recycling button for a long time to

realize automatic material collection, which is convenient and fast.

10. Accurate and efficient: each time only about 10s to complete.

Operating system

Touch screen operation, simple operation, 5 minutes to learn to

operate, barrier free, Chinese and English optional.

CCD system

Empty components detection: CCD detection can identify the above

01005, and the docking accuracy is ± 0.08.

Splicing system

Stepper motor drive, special gear structure. accurate, patented

structure design, success rate 98%.

Feeding system

Mold manufacturing, more than 2000 machines are verified in

the customer's factory, with perfect stability.

Success rate of splicing: 99.19%

| SMT Tape Automatic Splice Station | |||

| Mode | I.C.T-ASM08 | I.C.T-AISM08 | I.C.T-AISM16 |

| Applicable Mounter | Full SMT brand | ||

| Splicing Mode | Auto cutting and Splicing | ||

| Splicing Tape Size | 32mm | 32mm | 32mm*2 |

| Splicing Tape Package | Reel | ||

| Splicing Cycle Time | 6-12sec (excluding manual operation and empty tape detection time) | ||

| Passing rate on Mounter | 95% | 98% | 98% |

| Dimension / mm | 550*470*1300 | 400*470*1400 | 360*310*1320 |

| Weight | Approx: 65KG | Approx: 65KG | Approx: 70KG |

* The data is obtained under ambient temperature of 25℃ and humidity of 60%.

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

FAQ:

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT