D600 (LENS)

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

The I.C.T dispensing system has significant strength in cost performance. Being reliable, durable, and concisely designed, it can be applied to PCB and base materials of different specifications. The UFD operating software ensures the stability and reliability of the system. The system is designed for chip sealing, PCB assembly, SMT red glue dispensing,led lens,and medical products. With adjustable track width, it can be applied to more products.

• High cost performance;

• Non-contact jet valve to realize smaller dispensing diameter and wider application area

• Jet valve can improve the reliability and uniformity of dispensing, and improve the output and material utilization rate;

• Minimum width of excessive glue can be controlled in 0.2mm(related to the configuration and glue);

• Chip edge identification is much more accurate than mark-point identification.

• ID identification, automatic program calling, fool-proofing and data statistics function helps to realize smart manufacturing.

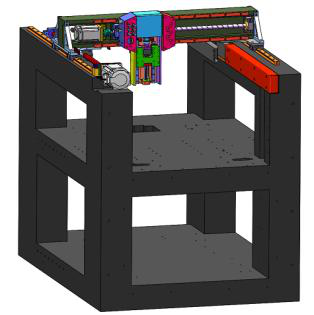

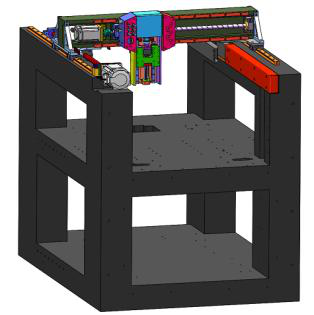

Platform System

Integral frame, marble platform supporting moving parts, moving parts using imported accessories, to ensure high accuracy and stability of equipment operation.

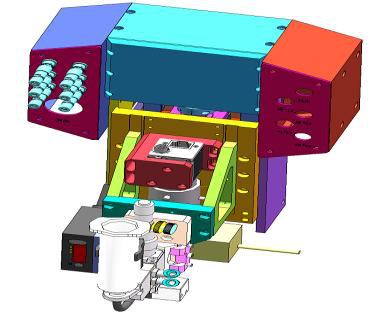

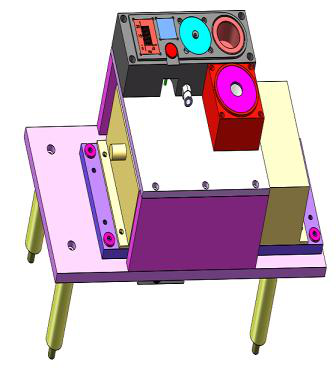

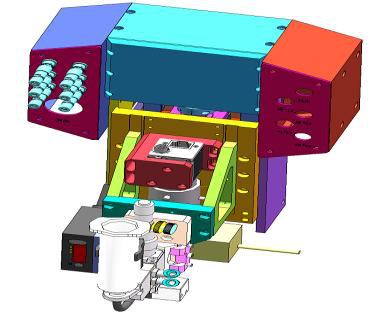

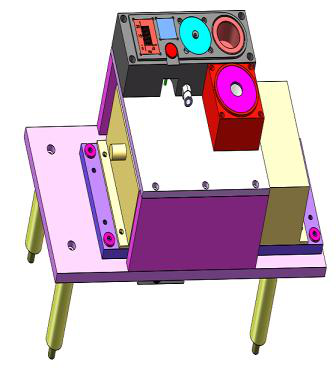

Dispensing System

Needle dispensing and spray valve dispensing can be selected. Spray valve dispensing can be fixed and rotary. CCD camera, laser altimeter and glue sensor can be selected.

Calibration System

Calibration Platform Standards: 0.1mg Electronic Scale, Scale, Ceramic Plate, Mechanical Height Detection, Vacuum Cleaning, Gluing Cup

Industry:

• Underfill

• Led lens

• Pin encapsulation

• Conformal coating

• Edge/corner bonding

• Surface mounted package

• Package on package (POP)

• Dam & fill

• Red glue dispensing

• FPC reinforcement

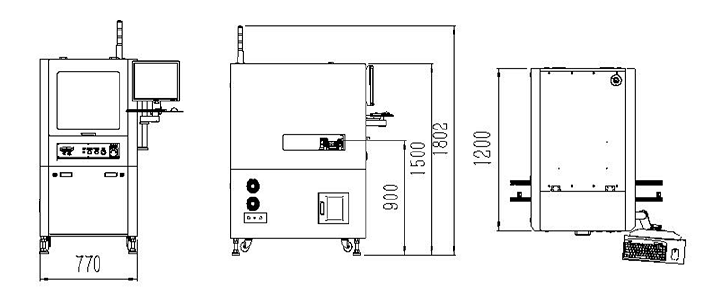

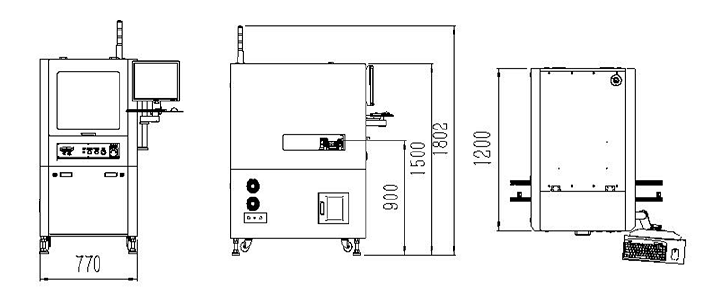

Specification: Automatic Glue Dispenser Machine SMT

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

FAQ

1: What is an automatic glue dispenser machine in SMT assembly, and how does it streamline production?

Answer: An automatic glue dispenser machine in SMT (Surface Mount Technology) assembly is a specialized device used to apply adhesive accurately onto electronic components and PCBs. It automates the dispensing process, ensuring precise placement and uniformity of adhesive application. This streamlines production by reducing manual labor, minimizing errors, and increasing efficiency in the assembly line. It's particularly useful for high-volume manufacturing where consistency and speed are crucial.

2: What types of adhesive can be used with an automatic glue dispenser machine in SMT assembly?

Answer: Various types of adhesives can be utilized with an automatic glue dispenser machine in SMT assembly, including epoxies, silicones, acrylics, and UV-curable adhesives. The choice of adhesive depends on factors such as the specific application requirements, material compatibility, curing time, and environmental conditions. It's essential to select an adhesive that offers the desired bonding strength, flexibility, and resistance to factors like temperature, moisture, and chemicals.

3: How can I optimize the performance of an automatic glue dispenser machine in SMT assembly?

Answer: To optimize the performance of an automatic glue dispenser machine in SMT assembly, regular maintenance and proper operation are crucial. This includes cleaning the machine regularly to prevent clogging or buildup of adhesive residues, calibrating the dispensing parameters for accurate and consistent application, and inspecting and replacing worn or damaged parts as needed. Additionally, providing comprehensive training to operators on machine operation, maintenance procedures, and troubleshooting techniques can help maximize efficiency and minimize downtime in the assembly process.

The I.C.T dispensing system has significant strength in cost performance. Being reliable, durable, and concisely designed, it can be applied to PCB and base materials of different specifications. The UFD operating software ensures the stability and reliability of the system. The system is designed for chip sealing, PCB assembly, SMT red glue dispensing,led lens,and medical products. With adjustable track width, it can be applied to more products.

• High cost performance;

• Non-contact jet valve to realize smaller dispensing diameter and wider application area

• Jet valve can improve the reliability and uniformity of dispensing, and improve the output and material utilization rate;

• Minimum width of excessive glue can be controlled in 0.2mm(related to the configuration and glue);

• Chip edge identification is much more accurate than mark-point identification.

• ID identification, automatic program calling, fool-proofing and data statistics function helps to realize smart manufacturing.

Platform System

Integral frame, marble platform supporting moving parts, moving parts using imported accessories, to ensure high accuracy and stability of equipment operation.

Dispensing System

Needle dispensing and spray valve dispensing can be selected. Spray valve dispensing can be fixed and rotary. CCD camera, laser altimeter and glue sensor can be selected.

Calibration System

Calibration Platform Standards: 0.1mg Electronic Scale, Scale, Ceramic Plate, Mechanical Height Detection, Vacuum Cleaning, Gluing Cup

Industry:

• Underfill

• Led lens

• Pin encapsulation

• Conformal coating

• Edge/corner bonding

• Surface mounted package

• Package on package (POP)

• Dam & fill

• Red glue dispensing

• FPC reinforcement

Specification: Automatic Glue Dispenser Machine SMT

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

FAQ

1: What is an automatic glue dispenser machine in SMT assembly, and how does it streamline production?

Answer: An automatic glue dispenser machine in SMT (Surface Mount Technology) assembly is a specialized device used to apply adhesive accurately onto electronic components and PCBs. It automates the dispensing process, ensuring precise placement and uniformity of adhesive application. This streamlines production by reducing manual labor, minimizing errors, and increasing efficiency in the assembly line. It's particularly useful for high-volume manufacturing where consistency and speed are crucial.

2: What types of adhesive can be used with an automatic glue dispenser machine in SMT assembly?

Answer: Various types of adhesives can be utilized with an automatic glue dispenser machine in SMT assembly, including epoxies, silicones, acrylics, and UV-curable adhesives. The choice of adhesive depends on factors such as the specific application requirements, material compatibility, curing time, and environmental conditions. It's essential to select an adhesive that offers the desired bonding strength, flexibility, and resistance to factors like temperature, moisture, and chemicals.

3: How can I optimize the performance of an automatic glue dispenser machine in SMT assembly?

Answer: To optimize the performance of an automatic glue dispenser machine in SMT assembly, regular maintenance and proper operation are crucial. This includes cleaning the machine regularly to prevent clogging or buildup of adhesive residues, calibrating the dispensing parameters for accurate and consistent application, and inspecting and replacing worn or damaged parts as needed. Additionally, providing comprehensive training to operators on machine operation, maintenance procedures, and troubleshooting techniques can help maximize efficiency and minimize downtime in the assembly process.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

Successful Experience:

I.C.T's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

Successful Experience:

I.C.T's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT