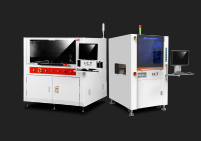

1.Modular design, optional assembly as per client’s requirement.

2.Solid aluminum structure design improves equipment stability.

3.Smooth stainless steel screw to adjust the width of the rail.

4.Variable speed control.

5.Using a dedicated aluminum slot for transfer orbit to prevent PCB stuck. 6.Heavier bottom design, not easily shift. 7.Machine length can be customized.

English

English