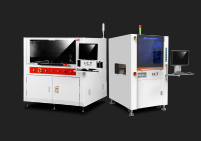

Infeed for Wave Soldering Machine

Configuration: |

Motor | 2HP,made by AIDELI |

Inverter | 2HP,made by AIDELI |

Main body | 40×40mm, aluminium |

Rail | 40×60mm, aluminium |

Specification: |

Dimension(mm) | 800*600*950mm/set |

PCB Width | 50 – 350mm(adjustable) |

PCB Thickness | 0.6 – 6.0mm |

Transport Height | 750±20mm |

Control Mode | Motor |

Power | Max 20 VA |

PCB Direction | L to R or R to L |

Power Supply | 1 PH AC 220V 50/60Hz (Option:110V to 380V) |

Weight | 220Kg/set |

|

|

|

|

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

FAQ 1: What is the Purpose of an Infeed for a Wave Soldering Machine?

Question: What is the purpose of an infeed for a wave soldering machine?

Answer: The infeed for a wave soldering machine is designed to automate and streamline the process of feeding printed circuit boards (PCBs) into the soldering system. It ensures precise and consistent alignment of PCBs as they enter the wave soldering machine, enhancing efficiency and minimizing errors. This automation reduces manual handling, improves throughput, and ensures high-quality soldering results.

FAQ 2: How Does an Infeed System Enhance the Performance of a Wave Soldering Machine?

Question: How does an infeed system enhance the performance of a wave soldering machine?

Answer: An infeed system enhances the performance of a wave soldering machine by providing a steady and controlled flow of PCBs into the soldering area. This consistent feed rate prevents bottlenecks and ensures that each PCB is properly positioned for optimal soldering. As a result, the soldering process becomes more efficient, with reduced downtime and increased production rates. Additionally, it helps in maintaining uniform solder joints, thereby improving the overall quality of the finished products.

FAQ 3: What Features Should I Consider When Choosing an Infeed for a Wave Soldering Machine?

Question: What features should I consider when choosing an infeed for a wave soldering machine?

Answer: When choosing an infeed for a wave soldering machine, consider features such as adjustable conveyor speed, compatibility with various PCB sizes and thicknesses, precise alignment mechanisms, and easy integration with existing soldering equipment. Look for systems with robust construction, reliable performance, and minimal maintenance requirements. Additionally, user-friendly controls and good customer support can greatly enhance the efficiency and longevity of the infeed system in your manufacturing process.

English

English