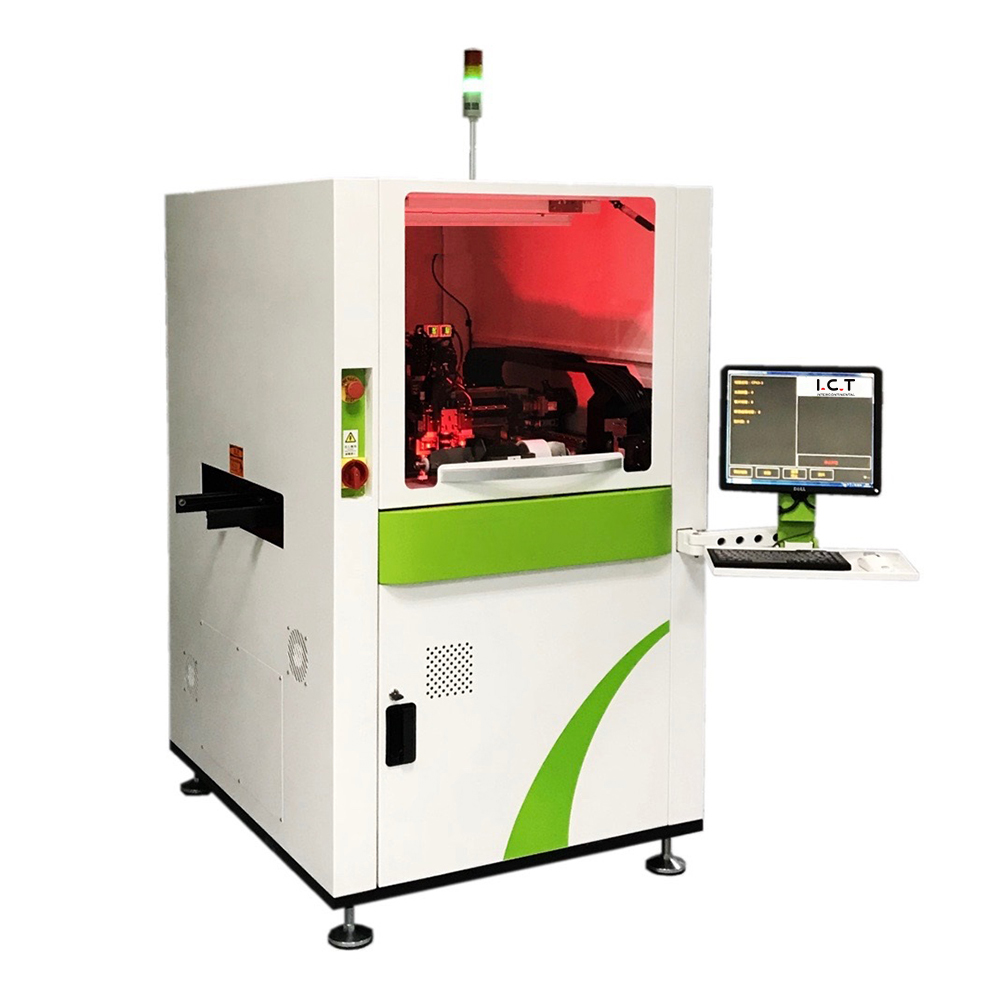

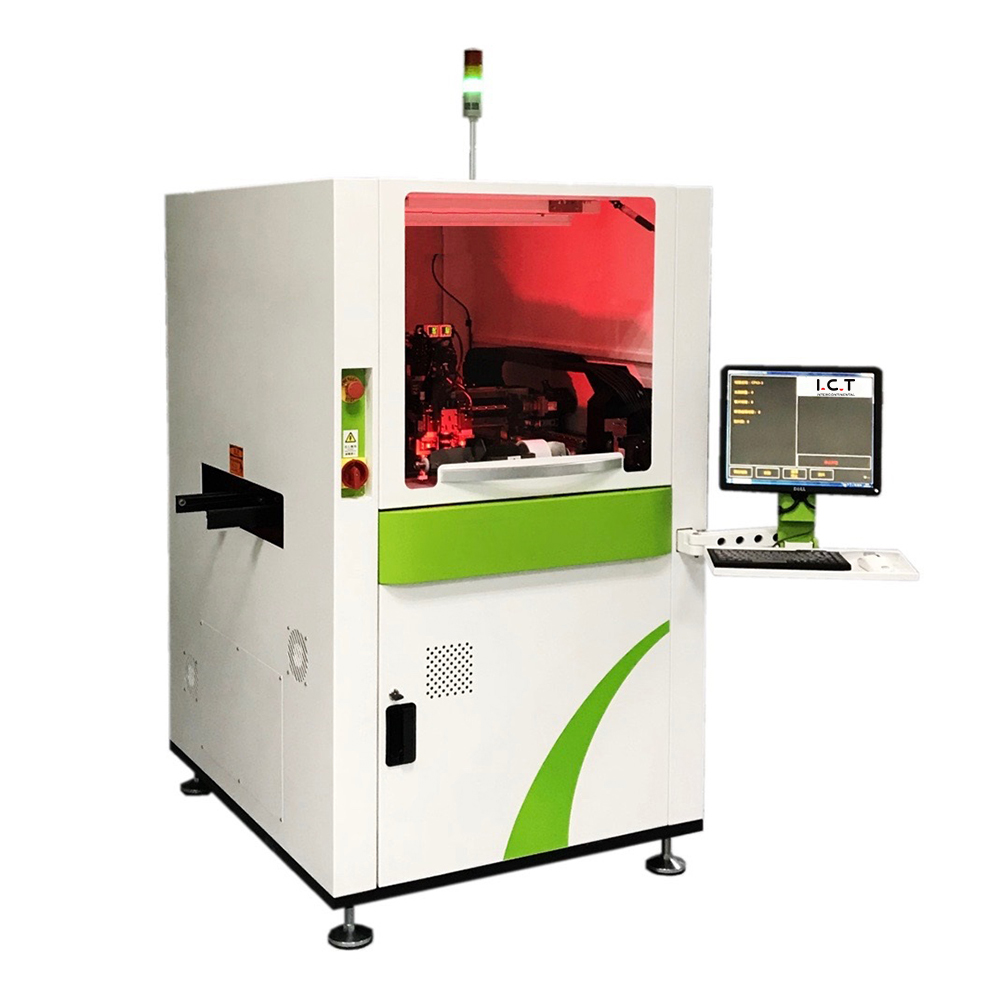

I.C.T-310P

I.C.T

Inline Label Sticker

| Availability: | |

|---|---|

| Quantity: | |

This unit is used to mount Various barcodes label (1D, 2D, labels with different background paper colors),Various film products (translucent, opaque, different colors, different thicknesses).

Features:

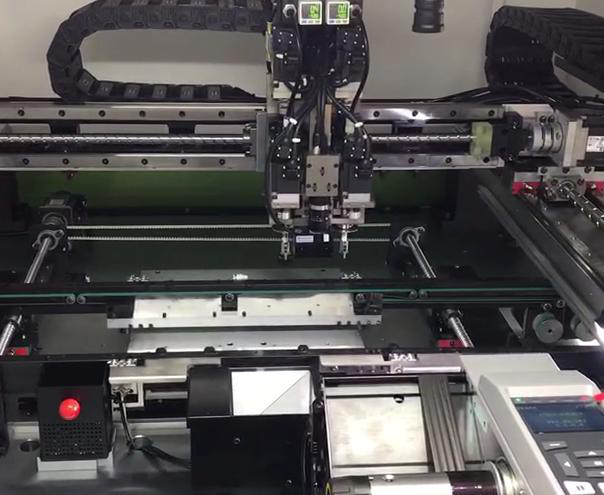

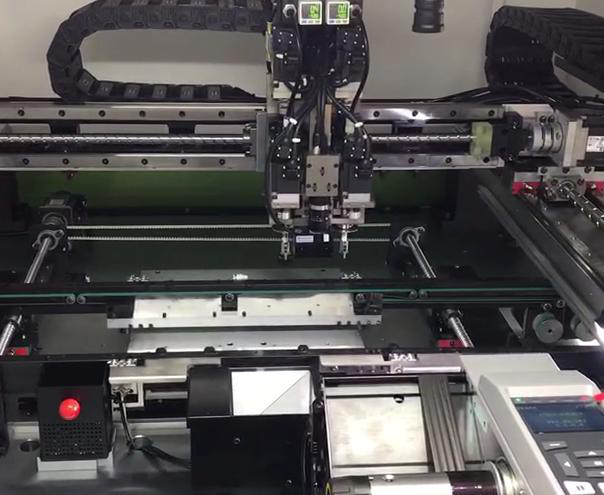

Transport system

The unique belt conveyor can effectively prevent stuck pcb.The motor controls the speed is precise.PCB entry and exit directions are freely available. Automatic width adjustment.

Feeder system

Two feeder positions,maximum width of 180mm feeder,have high versatility, electronic link mode, visual recognition, effectively shorten the installation time and improve efficiency.

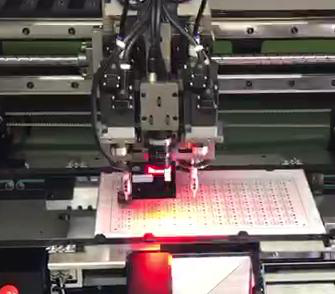

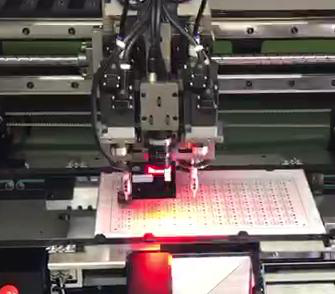

Mount system

The nozzle is independently controlled by double stepping motors and double slide rail to ensure accurate and stable pressure.

Operat system

Windows,Friendly MMI interface, teaching and navigation function.Operation log, fault record analysis and other diagnostic functions. New program is controlled within 5-10 minutes.

Mark system

PCB Mark identification,bad mark recognition function (automatic springboard),intelligent guidance of program making,barcode reading.

Printing system

With Zebra printer, different contents can be printed online, printing and mounting can run synchronously, which can realize the flexibility of label mounting.

| Item | I.C.T-310 | I.C.T-310P |

| Internal Printer | N/A | Zebra Brand |

| Speed | 3500Pcs/H | |

| Label Size | 3*3 ~ 50*50mm | |

| Labeling Precision | ±0.05mm | |

| Labeling Angle | 360° | |

| Feeder Input | 2 | 1 |

| PCB Size | L50*W80mm ~L450 * W350mm; Thickness 0.5mm-6mm | |

| Top Surface Height of PCB | <25mm | |

| Position System | 5M CCD | |

| Operation Mode | X,Y,Z,R movement(Servo Motor) | |

| Power | AC220V/50Hz, Total power: 1kva | |

| Body Size | L1000 *W1200 *H1500 mm | |

| Machine weight | 1250Kg | |

FAQ

This unit is used to mount Various barcodes label (1D, 2D, labels with different background paper colors),Various film products (translucent, opaque, different colors, different thicknesses).

Features:

Transport system

The unique belt conveyor can effectively prevent stuck pcb.The motor controls the speed is precise.PCB entry and exit directions are freely available. Automatic width adjustment.

Feeder system

Two feeder positions,maximum width of 180mm feeder,have high versatility, electronic link mode, visual recognition, effectively shorten the installation time and improve efficiency.

Mount system

The nozzle is independently controlled by double stepping motors and double slide rail to ensure accurate and stable pressure.

Operat system

Windows,Friendly MMI interface, teaching and navigation function.Operation log, fault record analysis and other diagnostic functions. New program is controlled within 5-10 minutes.

Mark system

PCB Mark identification,bad mark recognition function (automatic springboard),intelligent guidance of program making,barcode reading.

Printing system

With Zebra printer, different contents can be printed online, printing and mounting can run synchronously, which can realize the flexibility of label mounting.

| Item | I.C.T-310 | I.C.T-310P |

| Internal Printer | N/A | Zebra Brand |

| Speed | 3500Pcs/H | |

| Label Size | 3*3 ~ 50*50mm | |

| Labeling Precision | ±0.05mm | |

| Labeling Angle | 360° | |

| Feeder Input | 2 | 1 |

| PCB Size | L50*W80mm ~L450 * W350mm; Thickness 0.5mm-6mm | |

| Top Surface Height of PCB | <25mm | |

| Position System | 5M CCD | |

| Operation Mode | X,Y,Z,R movement(Servo Motor) | |

| Power | AC220V/50Hz, Total power: 1kva | |

| Body Size | L1000 *W1200 *H1500 mm | |

| Machine weight | 1250Kg | |

FAQ

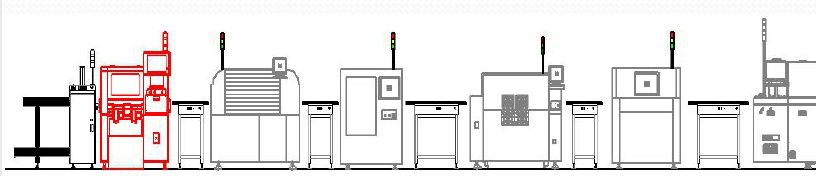

Successful Experience:

Eta's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

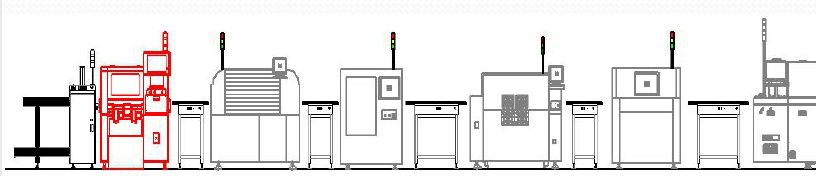

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

Successful Experience:

Eta's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT