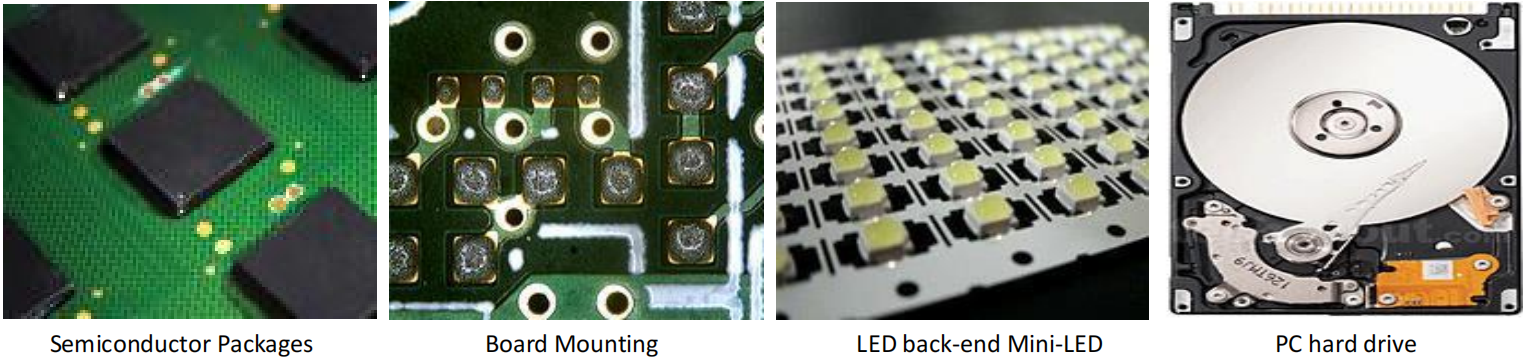

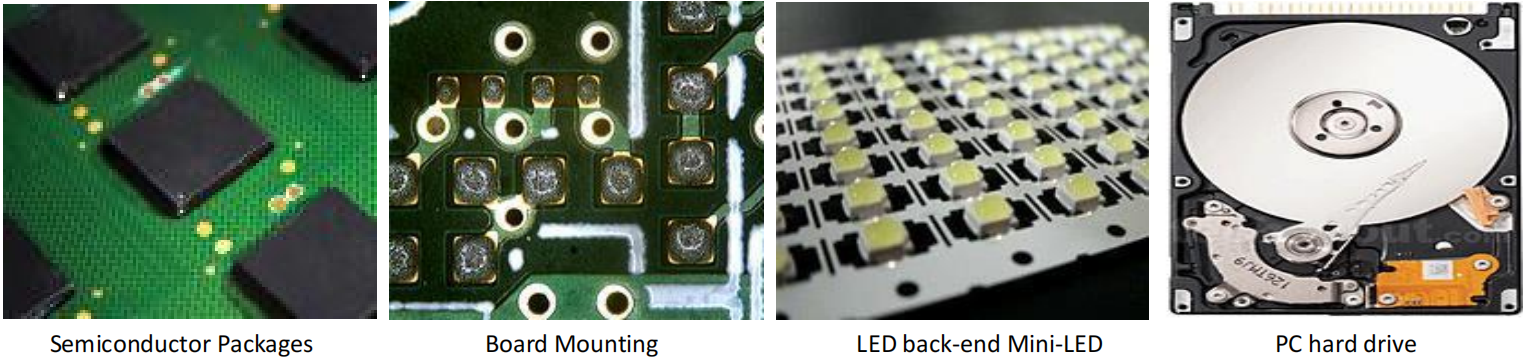

1. Quickly customize a dedicated platform according to customer needs;

2. By measuring any three points on the PCB, the plane height is calculated, and the needle height is automatically compensated based on the measured height data;

3. Efficient image processing speed reduces visual retrieval and visual inspection time;

4. Non-contact laser can detect 1μm warpage of the substrate;

5. High-speed micro-spraying of high-viscosity materials, automatic correction and compensation of chip cutting and welding errors;

6. Solder paste printing, small amount of high-speed dot spraying, small dot spacing.

Application of High Precision SMT PCB Dispensing System

Features of High Precision SMT PCB Dispensing System

Transmission Structure System:

1.The machine adopts X Y linear motor drive control, the reciprocating position accuracy is 3σ±5um (X, Y, Z axis ), and the dynamic position accuracy is 3σ±3um (X, Y axis);

2. Load-type gantry structure ensures the stability and accuracy of the machine during high-speed movement.

Function configuration:

1.Customize the exclusive platform to better suit the actual needs of customers;

2. Automatic correction of substrate warp height;

3. Penetration monitoring function, with upper and lower dual cameras, can monitor the material penetration under the flipchip in real time throughout the process, and automatically feedback to adjust the next filling

English

English