I.C.T-9200

I.C.T

X-RAY machine

| Availability: | |

|---|---|

| Quantity: | |

X-Ray I.C.T-9200 Introduction:

The I.C.T-9200 is designed to provide high-resolution X-ray imaging for the electronics industry. This versatile system is effective for many applications in the PCB manufacturing process. This includes semiconductors such as BGA, CSP, LGA, POP, SIP, QFN, flip chips, COB, and LED. The I.C.T-9200 is a powerful support tool for process development, process monitoring, and refinement of rework operations.

Features:

1. 130KV closed X-ray tube;

2. High-speed million high-resolution FPD detector, 6-axis motion system, to meet various high-demand detection needs;

3. Windows navigation, convenient target tracking;

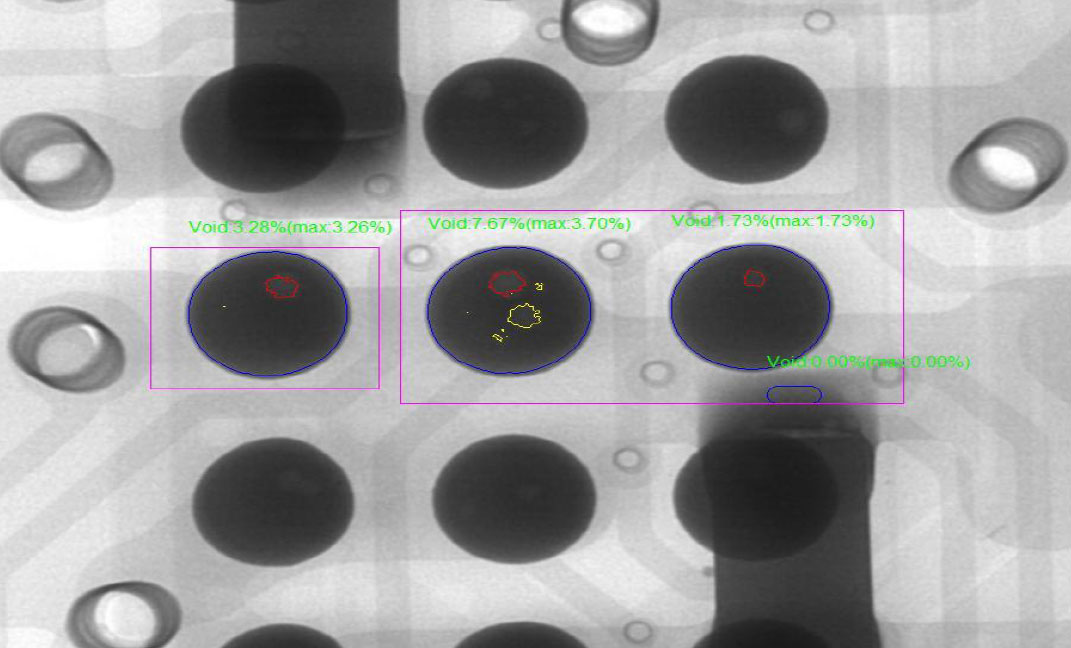

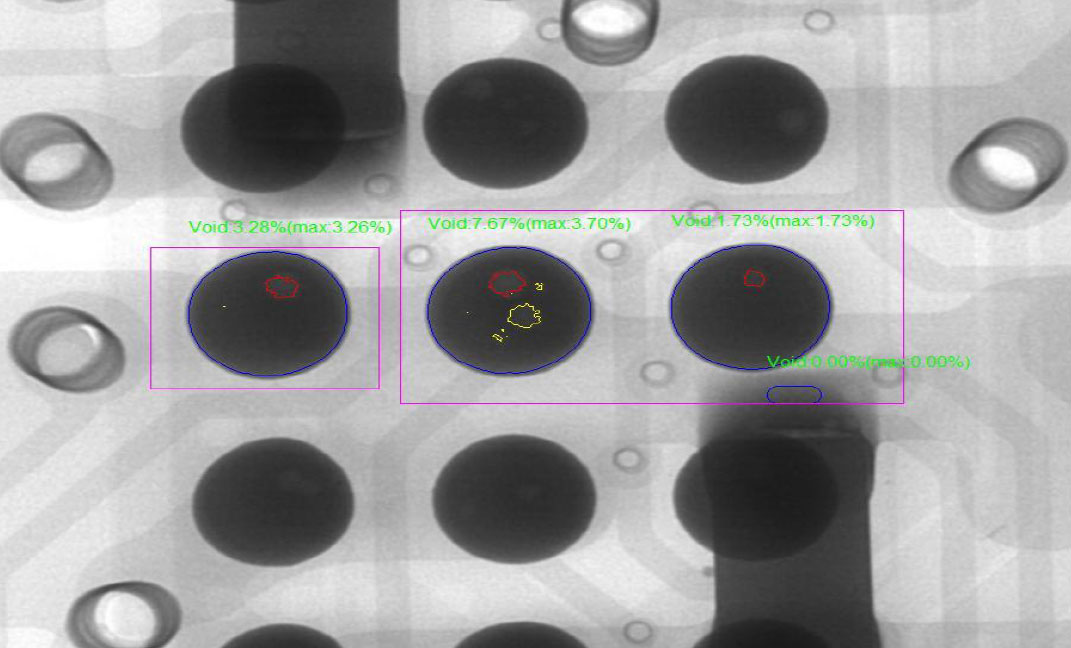

4. BGA void area automatic measurement and report generation;

5. Multifunctional DXI image processing system with multiple image inspection programs with XY programming;

6. The machine comes with UPS to reduce the damage to the equipment caused by sudden power failure;

7. Configure the energy real-time monitoring system;

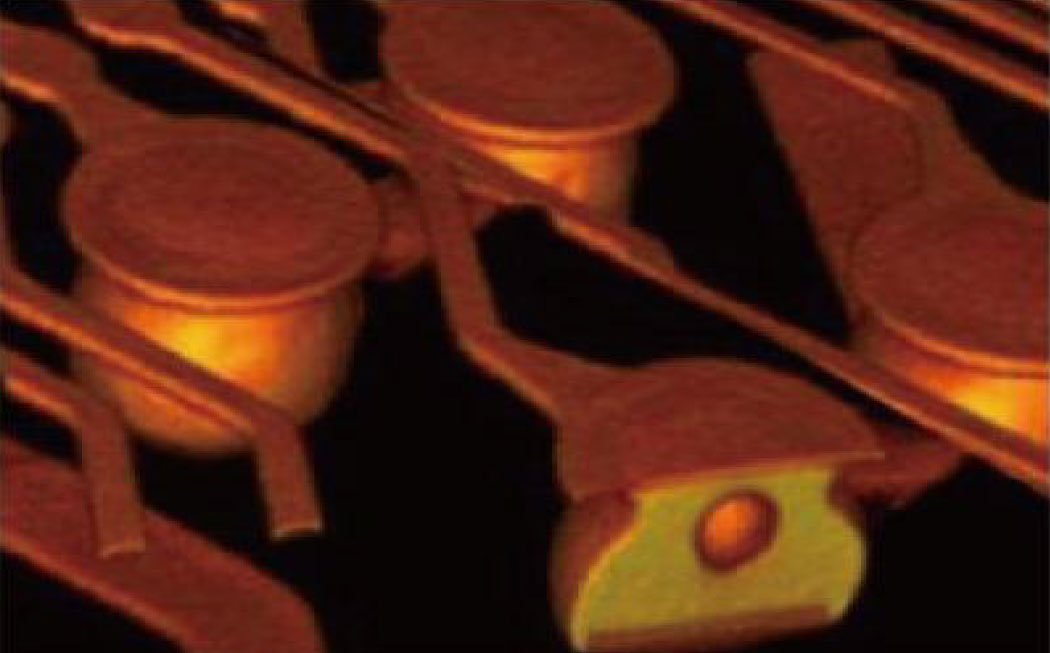

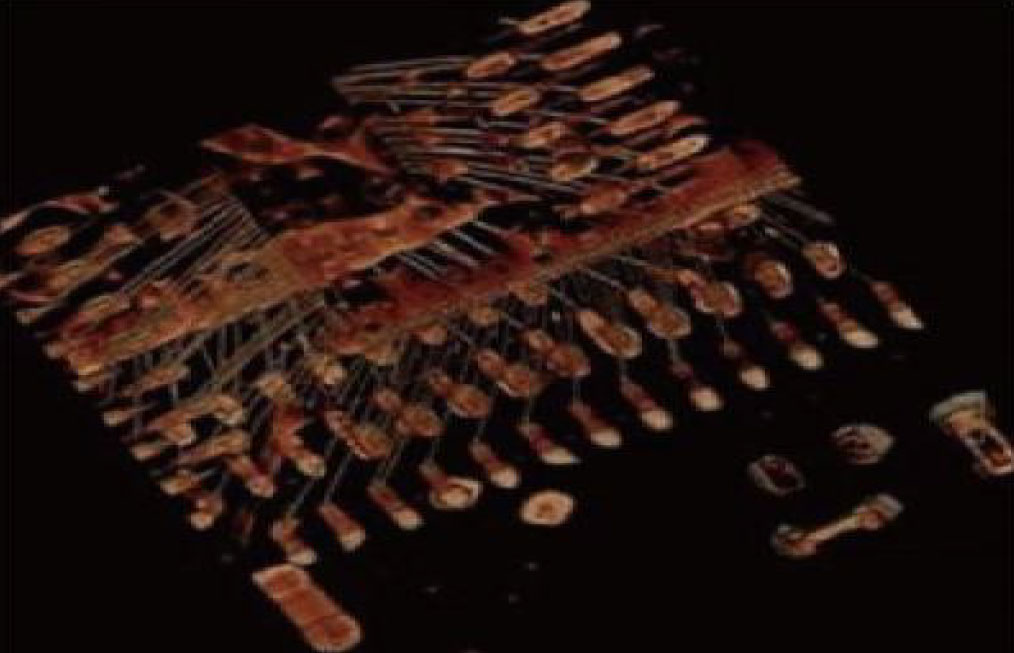

8. 3D CT scanning system. (Planar CT+Cone beam CT);

9. Ergonomic design, friendly man-machine interface;

10. High safety, with EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray.

BGA void rate calculation

Safely Electromagnetic Interloc & khardware protection

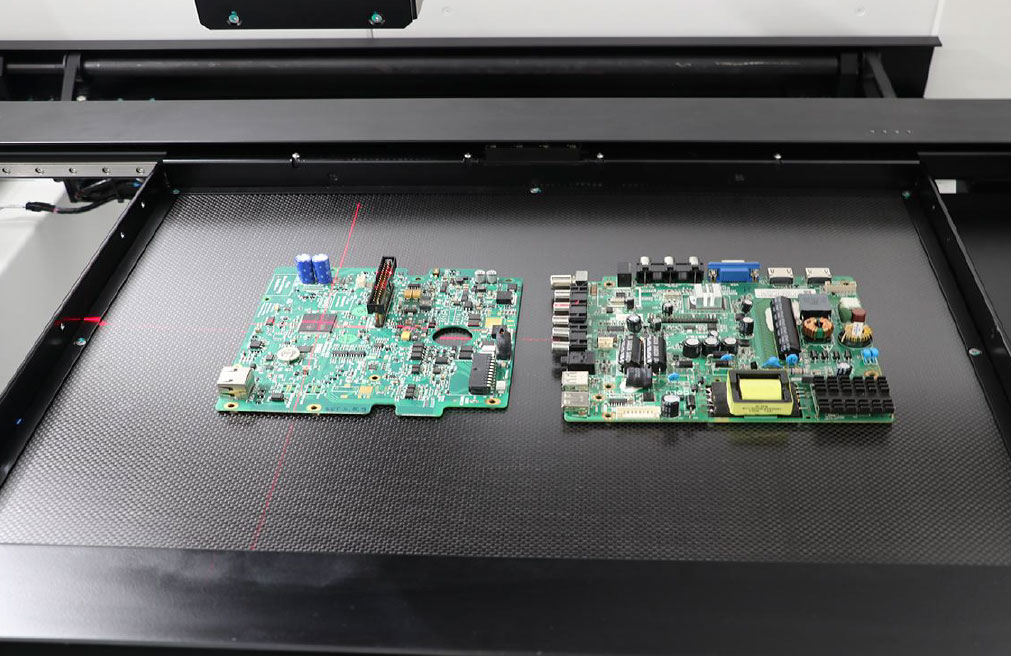

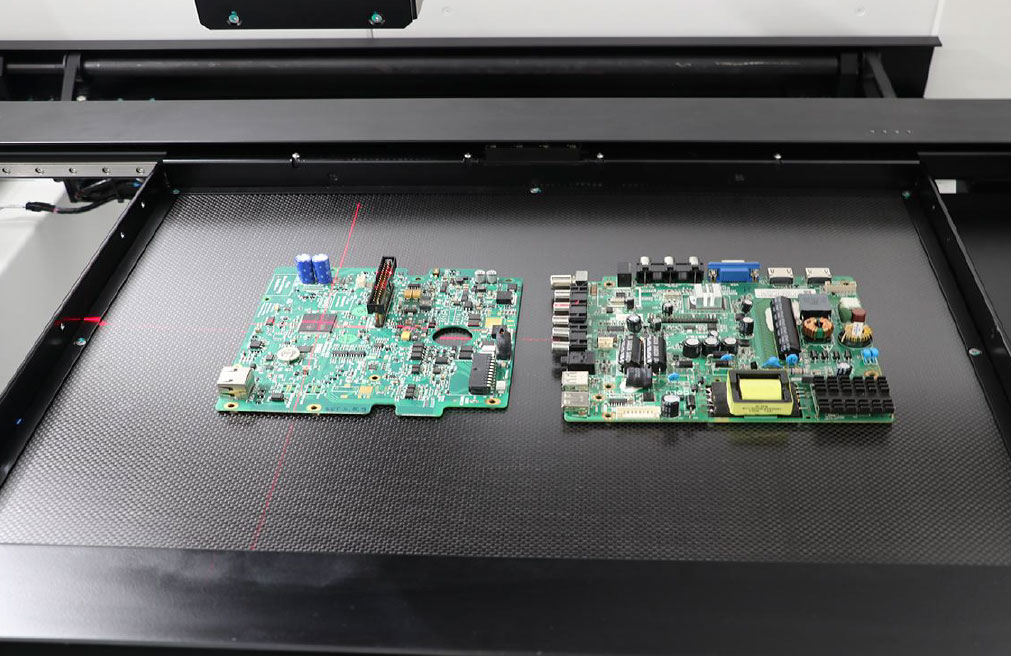

Large Size Inspection Table

Real-time Monitoring of Radiation

SMT, BGA, CSP, Flip Chip, LED Detection,Semiconductor, Packaging components, Battery Industry,Electronic components, Automotive parts, Photo-voltaic,Aluminium Die-casting, Moulding Plastic.Ceramics, other special industries.

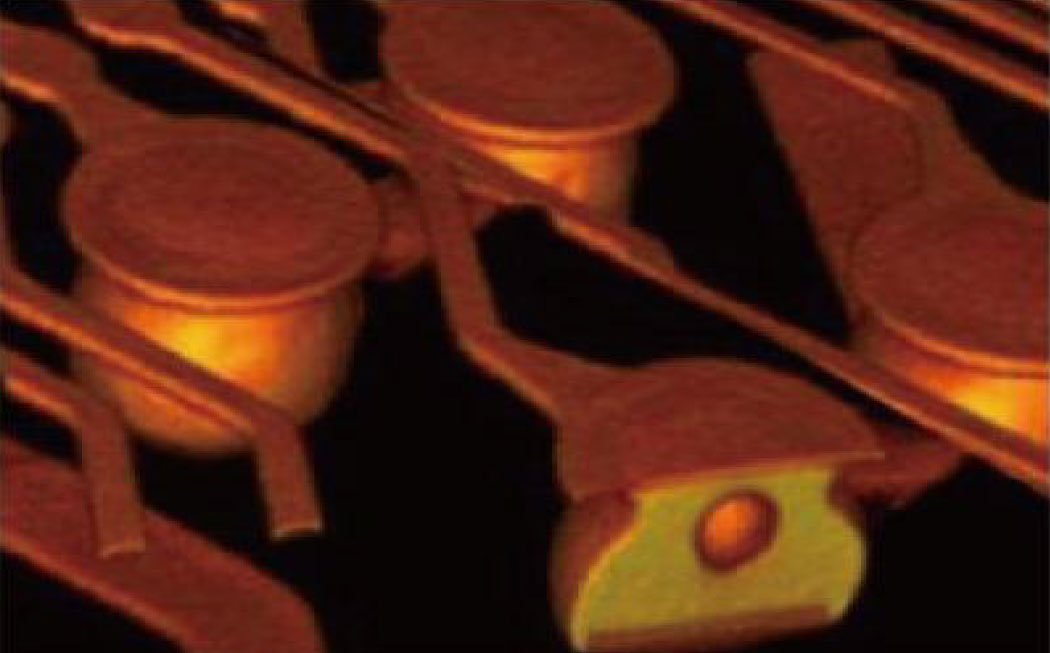

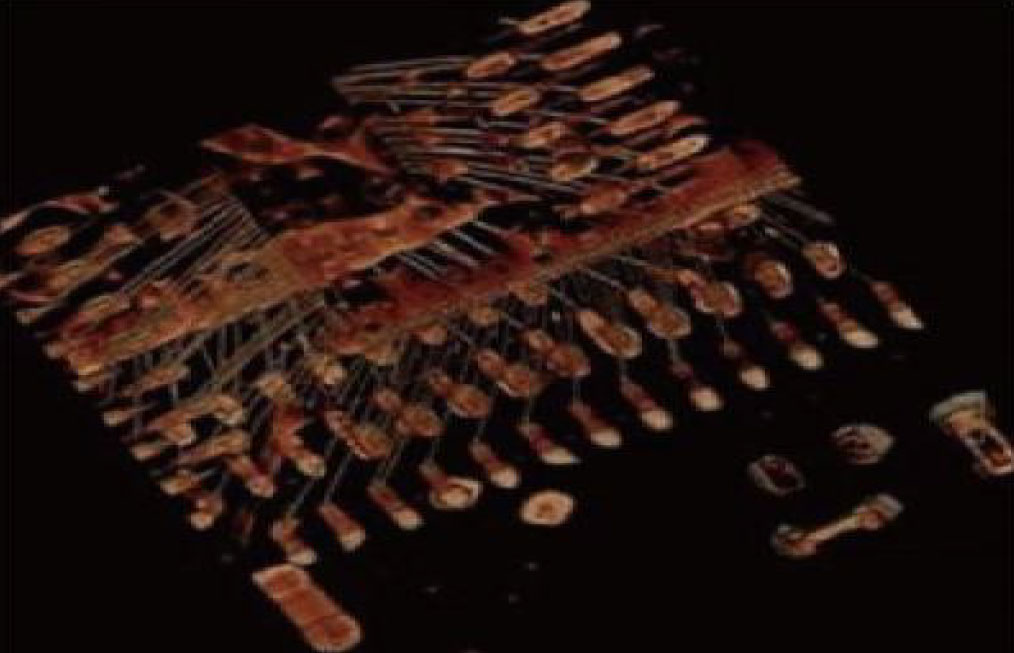

BGA 3D CT Detection

IC 3D CT Detection

Lithium battery Detection

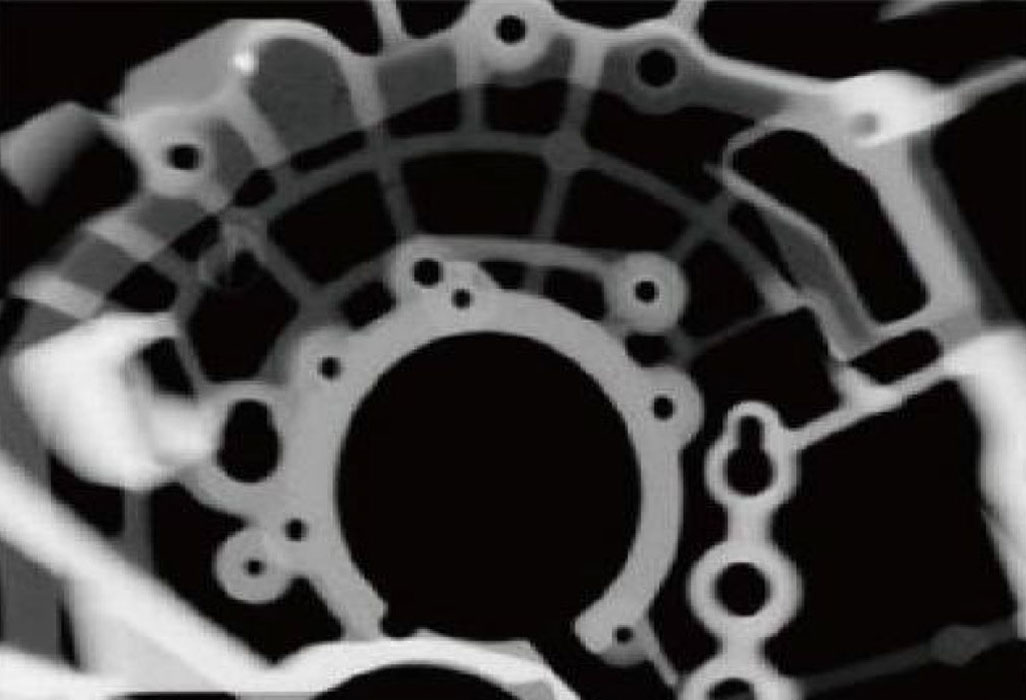

Die Casting Detection

Specification:

| Item | Model | I.C.T-9200 |

| X-Ray Tube | Max. Voltages, Type | 130kV/1000μA, Closed Micro Focus X-ray Tube |

| Detector Type | FPD | |

| Detector | Resolution | 1 μm |

| Pixel | 1536x1536 | |

| Detector Angle | Full 360° viewing angle, 2*70° tilt | |

| Operating System | Industrial PC, Win10 64-bit, i7 Processor | |

| System Computer | Monitor | 24” LCD |

| User Interface | I.C.T Multi-function DXI image processing system | |

| Working Platform | Max. Inspection Area | 510mm*670mm |

| Max. Loading Weight | 5kg[M size]; 30kg[L size] | |

| Movement Control | Joysticks, Mouse and Keypads | |

| Motion range (Up and Down) | 250mm | |

| PCBA thickness | 0.5-5mm | |

| PCBA craft side | 5mm | |

| PCBA warpage compensation | ±2mm | |

| Clearance Top&Bottom | 70mm&40mm | |

| Navigation | Camera | HD Camera, Laser point |

| Axis | Manipulator | 6-axis with Cam X / Y / T , Platform X / Y / Z |

| Axis Control | X, Y | |

| Equipment Features | Power Supply | AC 110~220V (±10%) 50Hz, 3kW |

| Outline Dimensions | 1700(W)*1660(D)*1900(H) mm | |

| System Weight | 3330 kg | |

| UPS | 1000VA, 800W | |

X-Ray I.C.T-9200 Introduction:

The I.C.T-9200 is designed to provide high-resolution X-ray imaging for the electronics industry. This versatile system is effective for many applications in the PCB manufacturing process. This includes semiconductors such as BGA, CSP, LGA, POP, SIP, QFN, flip chips, COB, and LED. The I.C.T-9200 is a powerful support tool for process development, process monitoring, and refinement of rework operations.

Features:

1. 130KV closed X-ray tube;

2. High-speed million high-resolution FPD detector, 6-axis motion system, to meet various high-demand detection needs;

3. Windows navigation, convenient target tracking;

4. BGA void area automatic measurement and report generation;

5. Multifunctional DXI image processing system with multiple image inspection programs with XY programming;

6. The machine comes with UPS to reduce the damage to the equipment caused by sudden power failure;

7. Configure the energy real-time monitoring system;

8. 3D CT scanning system. (Planar CT+Cone beam CT);

9. Ergonomic design, friendly man-machine interface;

10. High safety, with EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray.

BGA void rate calculation

Safely Electromagnetic Interloc & khardware protection

Large Size Inspection Table

Real-time Monitoring of Radiation

SMT, BGA, CSP, Flip Chip, LED Detection,Semiconductor, Packaging components, Battery Industry,Electronic components, Automotive parts, Photo-voltaic,Aluminium Die-casting, Moulding Plastic.Ceramics, other special industries.

BGA 3D CT Detection

IC 3D CT Detection

Lithium battery Detection

Die Casting Detection

Specification:

| Item | Model | I.C.T-9200 |

| X-Ray Tube | Max. Voltages, Type | 130kV/1000μA, Closed Micro Focus X-ray Tube |

| Detector Type | FPD | |

| Detector | Resolution | 1 μm |

| Pixel | 1536x1536 | |

| Detector Angle | Full 360° viewing angle, 2*70° tilt | |

| Operating System | Industrial PC, Win10 64-bit, i7 Processor | |

| System Computer | Monitor | 24” LCD |

| User Interface | I.C.T Multi-function DXI image processing system | |

| Working Platform | Max. Inspection Area | 510mm*670mm |

| Max. Loading Weight | 5kg[M size]; 30kg[L size] | |

| Movement Control | Joysticks, Mouse and Keypads | |

| Motion range (Up and Down) | 250mm | |

| PCBA thickness | 0.5-5mm | |

| PCBA craft side | 5mm | |

| PCBA warpage compensation | ±2mm | |

| Clearance Top&Bottom | 70mm&40mm | |

| Navigation | Camera | HD Camera, Laser point |

| Axis | Manipulator | 6-axis with Cam X / Y / T , Platform X / Y / Z |

| Axis Control | X, Y | |

| Equipment Features | Power Supply | AC 110~220V (±10%) 50Hz, 3kW |

| Outline Dimensions | 1700(W)*1660(D)*1900(H) mm | |

| System Weight | 3330 kg | |

| UPS | 1000VA, 800W | |

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT