I.C.T-Acrab450

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

I.C.T Acrab lead-free wave soldering machine has long-term positive feedback from customers. Its unparalleled heating performance and temperature control system meet the requirements of various welding processes, especially energy saving design has been a leading-edge product advantage, maximum reducing the using cost for customers.

TOP Advantage of Nitrogen Wave Soldering Machine:

Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to learn, easy to maintain.

Expertise: learn imported reflow oven’s advanced design concepts, and the components are using imported top brands.

Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

Safety: Based on the general rules of international design, close to imported reflow rating, the highest security level.

Stable: mature software, hardware and top production processes ensures stability of each equipment.

Design Concept

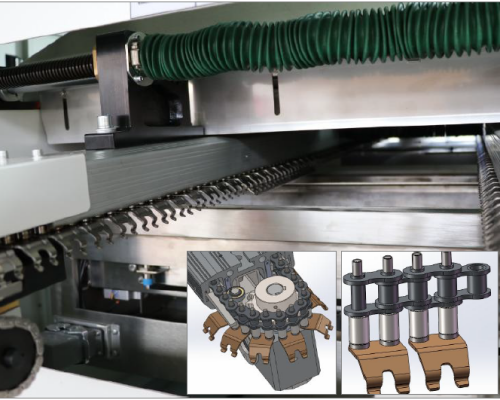

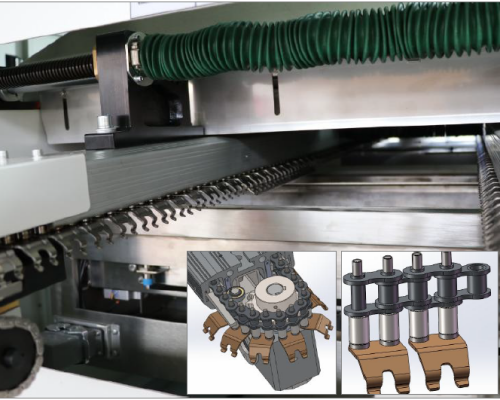

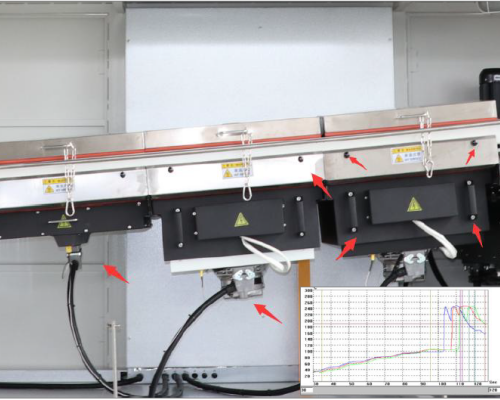

Conveyor System

Roller type double hook finger, force point increases roller sleeve,effectively reduce friction and wear.

Increase guide bracket and guide wheel, prevent chain knotting and clamping, and ensure transport stability.

Titanium finger no wetting and no deformation.

Full load > 60 kg.

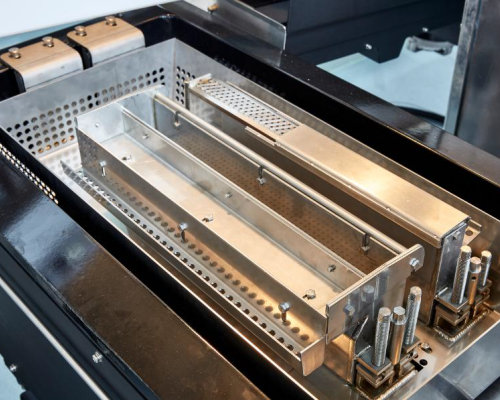

Spray System

316 stainless steel material, corrosion resistance.

Sealing structure design to prevent flux pollution.

Tool-free plug-in filter with self-contained air extraction system.

Cover is opened manually,conducive to maintenance.

Selective spray optional.

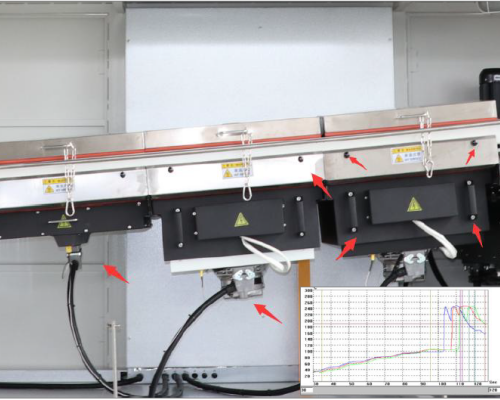

Preheating System

Efficient and stable heat conduction.

Design structure for maximizing preheating area.

All round high temperature cotton design to ensure temperature stability.

Heat-generating and heat-conducting parts and motors adopt top brands.

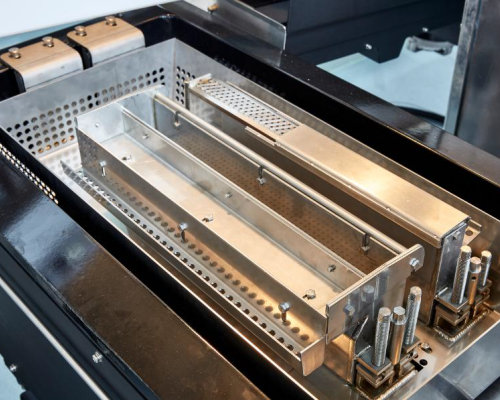

Soldering System

Steady solder flow channel design.

Wave peak stationarity less than 0.5mm.

Easy maintenance design structure.

Minimum oxidation of tin slag.

Wave peak Inverter Control.

Cooling System

Top and bottom convection modes.

High Power Cooling Fan.

Chiller is optional.

Control System

Humanized Operating Interface.

Standard circuit design, safe and reasonable.

Top brand for core parts

| Model | Acrab 350 | Acrab 450 |

| Dimension(mm) | 4420X1420X1750 | 4420X1520X1750 |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 33kw | 33kw |

| Operation Power | 8kw | 8kw |

| Control System | PC+PLC | PC+PLC |

| Preheating Zone | 3 | 3 |

| Preheating Length | 1800mm | 1800mm |

| Preheating Temp. | (Room Temperature)-250°C | (Room Temperature)-250°C |

| PCB Width(mm) | 50-350mm | 50-450mm |

| Finger | Spring Pressing Finger (Standard); Option:Spring Pressing Finger, Duck Mouth Finger | |

| Solder Pot Capacity | Lead-free 500kg | |

| Machine Weight(kg) | Approx.1600kg | Approx.1900kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

FAQ

Q: What is a Nitrogen Wave Soldering Machine?

A: A Nitrogen Wave Soldering Machine is an advanced soldering system that utilizes a nitrogen-rich environment during the soldering process. This minimizes oxidation, ensuring high-quality solder joints and improved reliability in electronic assemblies.

Q: What are the benefits of using a Nitrogen Wave Soldering Machine?

A: Using a Nitrogen Wave Soldering Machine results in reduced solder defects, improved wetting, and enhanced solder joint strength. This technology is particularly advantageous for lead-free soldering and high-reliability electronic applications.

Q: Is nitrogen gas supply required for this machine, and how does it work?

A: Yes, a nitrogen gas supply is essential for a Nitrogen Wave Soldering Machine. It works by creating a nitrogen-rich atmosphere in the soldering chamber, which displaces oxygen and prevents oxidation of the solder and PCB surfaces, resulting in superior soldering quality.

I.C.T Acrab lead-free wave soldering machine has long-term positive feedback from customers. Its unparalleled heating performance and temperature control system meet the requirements of various welding processes, especially energy saving design has been a leading-edge product advantage, maximum reducing the using cost for customers.

TOP Advantage of Nitrogen Wave Soldering Machine:

Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to learn, easy to maintain.

Expertise: learn imported reflow oven’s advanced design concepts, and the components are using imported top brands.

Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

Safety: Based on the general rules of international design, close to imported reflow rating, the highest security level.

Stable: mature software, hardware and top production processes ensures stability of each equipment.

Design Concept

Conveyor System

Roller type double hook finger, force point increases roller sleeve,effectively reduce friction and wear.

Increase guide bracket and guide wheel, prevent chain knotting and clamping, and ensure transport stability.

Titanium finger no wetting and no deformation.

Full load > 60 kg.

Spray System

316 stainless steel material, corrosion resistance.

Sealing structure design to prevent flux pollution.

Tool-free plug-in filter with self-contained air extraction system.

Cover is opened manually,conducive to maintenance.

Selective spray optional.

Preheating System

Efficient and stable heat conduction.

Design structure for maximizing preheating area.

All round high temperature cotton design to ensure temperature stability.

Heat-generating and heat-conducting parts and motors adopt top brands.

Soldering System

Steady solder flow channel design.

Wave peak stationarity less than 0.5mm.

Easy maintenance design structure.

Minimum oxidation of tin slag.

Wave peak Inverter Control.

Cooling System

Top and bottom convection modes.

High Power Cooling Fan.

Chiller is optional.

Control System

Humanized Operating Interface.

Standard circuit design, safe and reasonable.

Top brand for core parts

| Model | Acrab 350 | Acrab 450 |

| Dimension(mm) | 4420X1420X1750 | 4420X1520X1750 |

| Power Supply | 3P5W,380/220V 50Hz | 3P5W,380/220V 50Hz |

| Startup Power | 33kw | 33kw |

| Operation Power | 8kw | 8kw |

| Control System | PC+PLC | PC+PLC |

| Preheating Zone | 3 | 3 |

| Preheating Length | 1800mm | 1800mm |

| Preheating Temp. | (Room Temperature)-250°C | (Room Temperature)-250°C |

| PCB Width(mm) | 50-350mm | 50-450mm |

| Finger | Spring Pressing Finger (Standard); Option:Spring Pressing Finger, Duck Mouth Finger | |

| Solder Pot Capacity | Lead-free 500kg | |

| Machine Weight(kg) | Approx.1600kg | Approx.1900kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

FAQ

Q: What is a Nitrogen Wave Soldering Machine?

A: A Nitrogen Wave Soldering Machine is an advanced soldering system that utilizes a nitrogen-rich environment during the soldering process. This minimizes oxidation, ensuring high-quality solder joints and improved reliability in electronic assemblies.

Q: What are the benefits of using a Nitrogen Wave Soldering Machine?

A: Using a Nitrogen Wave Soldering Machine results in reduced solder defects, improved wetting, and enhanced solder joint strength. This technology is particularly advantageous for lead-free soldering and high-reliability electronic applications.

Q: Is nitrogen gas supply required for this machine, and how does it work?

A: Yes, a nitrogen gas supply is essential for a Nitrogen Wave Soldering Machine. It works by creating a nitrogen-rich atmosphere in the soldering chamber, which displaces oxygen and prevents oxidation of the solder and PCB surfaces, resulting in superior soldering quality.

FAQ:

Q: What is a wave soldering machine, and how does it work?

A: A wave soldering machine, such as those crafted by I.C.T, is an essential tool in electronics manufacturing. It precisely solders through-hole components on printed circuit boards (PCBs). I.C.T's machines ensure optimal soldering quality.

Q: What sets I.C.T's wave soldering machines apart from competitors?

A: I.C.T's machines are distinguished by their advanced technology, precise solder wave control, and comprehensive quality assurance measures, highlighting our manufacturing excellence.

Q: Can I.C.T's wave soldering machines accommodate various PCB sizes and configurations?

A: Yes, I.C.T's machines are adaptable, capable of handling diverse PCB sizes and configurations, ensuring flexibility in the manufacturing process.

Q: What types of soldering processes can I.C.T's machines perform?

A: I.C.T's machines excel in both leaded and lead-free soldering processes, demonstrating our commitment to compliance with industry standards.

FAQ 5: How does I.C.T ensure the soldering quality of their machines?

Answer: I.C.T employs rigorous quality control protocols, including real-time monitoring and precise temperature regulation, to guarantee exceptional soldering quality.

FAQ:

Q: What is a wave soldering machine, and how does it work?

A: A wave soldering machine, such as those crafted by I.C.T, is an essential tool in electronics manufacturing. It precisely solders through-hole components on printed circuit boards (PCBs). I.C.T's machines ensure optimal soldering quality.

Q: What sets I.C.T's wave soldering machines apart from competitors?

A: I.C.T's machines are distinguished by their advanced technology, precise solder wave control, and comprehensive quality assurance measures, highlighting our manufacturing excellence.

Q: Can I.C.T's wave soldering machines accommodate various PCB sizes and configurations?

A: Yes, I.C.T's machines are adaptable, capable of handling diverse PCB sizes and configurations, ensuring flexibility in the manufacturing process.

Q: What types of soldering processes can I.C.T's machines perform?

A: I.C.T's machines excel in both leaded and lead-free soldering processes, demonstrating our commitment to compliance with industry standards.

FAQ 5: How does I.C.T ensure the soldering quality of their machines?

Answer: I.C.T employs rigorous quality control protocols, including real-time monitoring and precise temperature regulation, to guarantee exceptional soldering quality.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT