S4020

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Expandable from 20 stations

Speeds up to 20,000/hour

Low maintenance feeder technology

Dual part detection – two parts in same chain slot.

Insertion Directions: 0°,90°,180°,270°

Jumper Wire Feeder Support

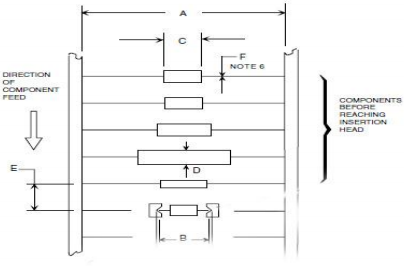

Neighbor components parallel distance E(pitch)=5.0mm

Tape width: 52mm

Max Component Body Length:C=16mm , Resistor:1/8W-2W

Axial Lead Component Kind:Diode、Resistor、Capacitor and so on.

Max body diameter D=5.0mm

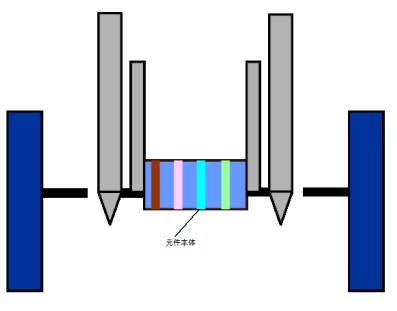

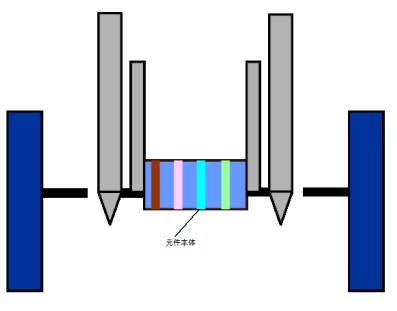

Insertion head work principal

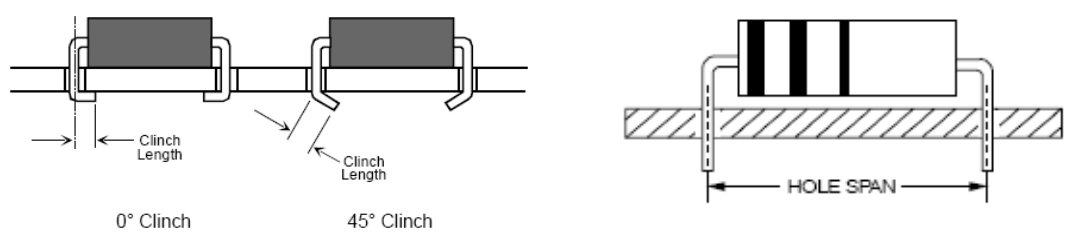

Hole Span:5~20mm

JW Span:5~30mm

Hole Diameter = Lead Diameter + 0.48mm ±0.08mm.(0.019") (0.003")

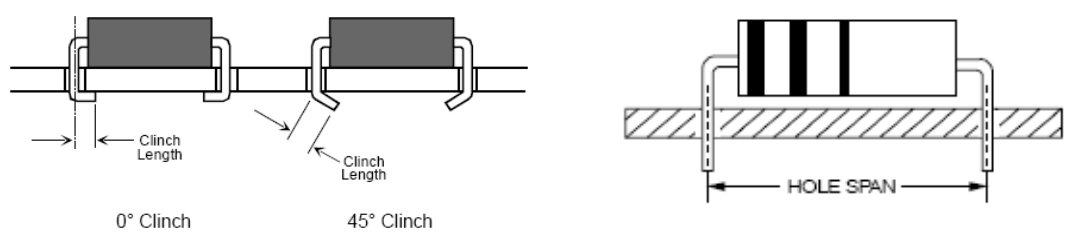

Clinch lead angle is adjustable in a range (0°- 45°). Clinch lead length is adjustable from 1.28mm (0.050") to 1.80mm (0.071") and is measured from the center of the insertion hole to the end of the lead.

| I.C.T-S4020 | |

| Actual Speed | 24000 CPH |

| Feeders | 20 |

| Accurancy | ±0.05mm |

| Plug-in Angle | 0,90,180,270° |

| Lead Spacing | 5-20mm |

| Power Supply | AC:220±10%,50/60HZ,2Kw |

| Dimension(mm) | L1700*W1500*H1800 |

| Weight | Approx:2100kg |

FAQ

Expandable from 20 stations

Speeds up to 20,000/hour

Low maintenance feeder technology

Dual part detection – two parts in same chain slot.

Insertion Directions: 0°,90°,180°,270°

Jumper Wire Feeder Support

Neighbor components parallel distance E(pitch)=5.0mm

Tape width: 52mm

Max Component Body Length:C=16mm , Resistor:1/8W-2W

Axial Lead Component Kind:Diode、Resistor、Capacitor and so on.

Max body diameter D=5.0mm

Insertion head work principal

Hole Span:5~20mm

JW Span:5~30mm

Hole Diameter = Lead Diameter + 0.48mm ±0.08mm.(0.019") (0.003")

Clinch lead angle is adjustable in a range (0°- 45°). Clinch lead length is adjustable from 1.28mm (0.050") to 1.80mm (0.071") and is measured from the center of the insertion hole to the end of the lead.

| I.C.T-S4020 | |

| Actual Speed | 24000 CPH |

| Feeders | 20 |

| Accurancy | ±0.05mm |

| Plug-in Angle | 0,90,180,270° |

| Lead Spacing | 5-20mm |

| Power Supply | AC:220±10%,50/60HZ,2Kw |

| Dimension(mm) | L1700*W1500*H1800 |

| Weight | Approx:2100kg |

FAQ

Full-auto SMT production line

Full-auto SMT production line

1. We have more than 20 years of SMT technical service experience and global service network with providing super high-quality after-sales service support locally.

2. We can provide professional advice from pre-sale to after-sale

3. We can help customers provide full service from machine use, installation and commissioning to product completion.

4. We have global spare parts warehouses, which can provide spare parts service support fastly.

5. We can offer more professional training for all customers.

1. We have more than 20 years of SMT technical service experience and global service network with providing super high-quality after-sales service support locally.

2. We can provide professional advice from pre-sale to after-sale

3. We can help customers provide full service from machine use, installation and commissioning to product completion.

4. We have global spare parts warehouses, which can provide spare parts service support fastly.

5. We can offer more professional training for all customers.