I.C.T-LV733

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

I.C.T LV Series Vacuum reflow oven unparalleled heating performance and temperature control system meets the requirements of various soldering processes, LV Series Vacuum Reflow Oven is high-end reflow products committed to keeping up with market demand to enhance customers competitiveness.Its new design concept fully meets the needs of increasingly diverse processes, And considering the future direction of the industry, entirely suitable for communications, automotive electronics, home appliances, computers and other consumer electronic products .

1.Control System: PC + Siemens PLC control system,accurate temperature control and more stable,ensures temperature stability rate to be

more than 99.99%.

2.Vacuum system:PCB directly enters the vacuum unit from soldering area. Start the vacuum process to reduce the vacuum pressure to

100mbar-5mbar. The internal gas such as pores and cavities overflows from the molten solder joint, which can reduce the void rate to less

than 2%.

3.Hot air system: first-class heating module, the best temperature zone interval design makes optimum temperature uniformity and repeat.The

effective utilization and thermal compensation efficiency,it needs less than 20 minutes from temperature control accuracy ± 1 ℃ ambient

temperature to a temperature stabilization .

4.Monitoring Software:Windows interface, traditional and simplified Chinese and English online free switch, and operator password

management, easy to operate.Operation records, temperature curve measurement and analysis functions, virtual simulation, fault

self-diagnosis, process monitoring, automatic generate and save process control documents, substrate transport dynamic display.

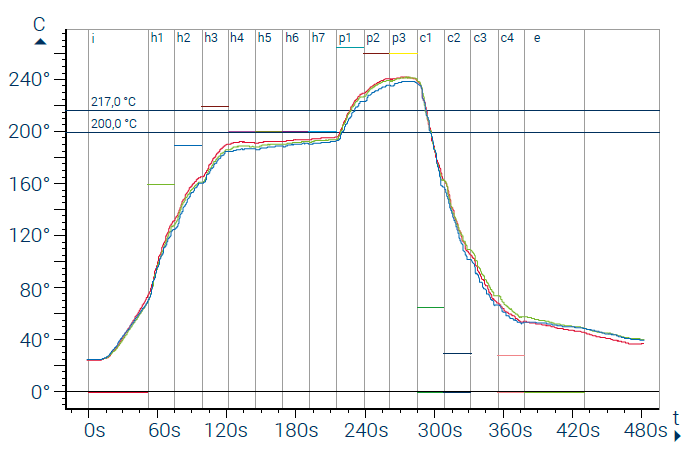

From zero to 240 °C due to optimized heat transfer

Each product has its own requirements in the manufacturing process. Optimized heat transfer over the entire soldering process is the basis for

best possible results.

The LV-Series offers flexibly controllable preheating zones within which your PCB is preheated and prepared for the actual soldering process.

The individual zones can be controlled independently of each other via fan frequency, and assure best possible processes.

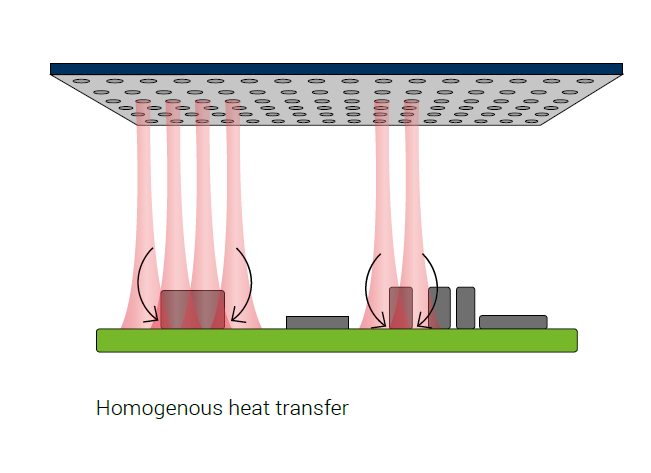

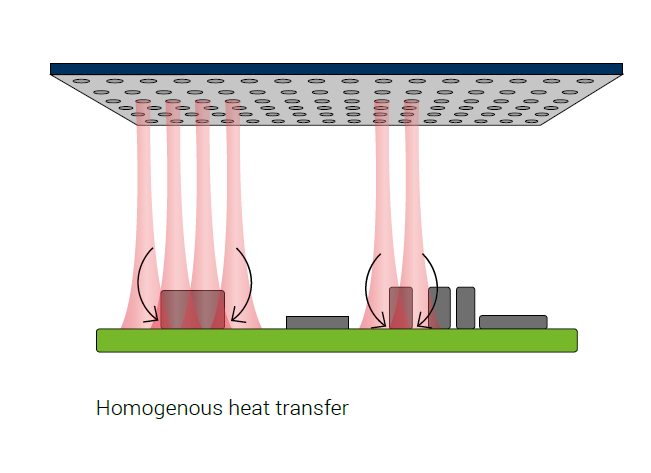

The LV-Series is equipped with special nozzle sheets for optimized heat transfer by means of uniform air flow over the PCBs. Flow speeds in the

upper and lower heat zones can be separately controlled, assuring that your PCB is heated up.

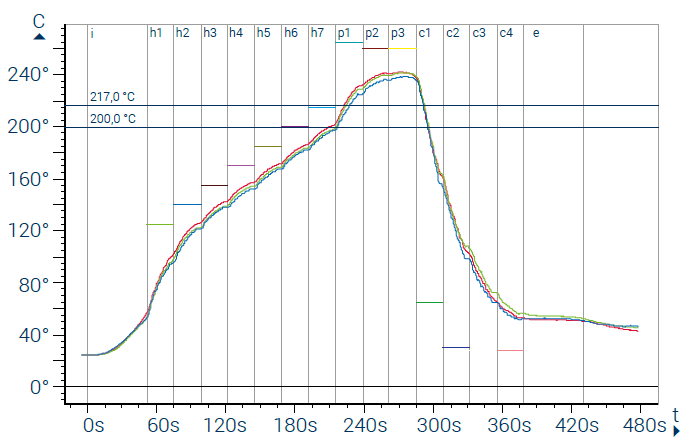

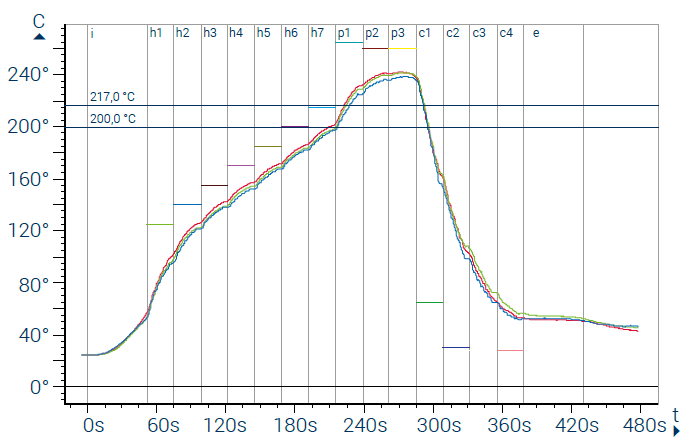

Saddle profile

The component is brought to a temperature of at least 240 °C for

soldering. Using a saddle profile the board is gradually heated in line

with pre-defined, individual temperature ranges. Even components

with differing thermal masses are heated homogeneously and

temperature differences minimised.

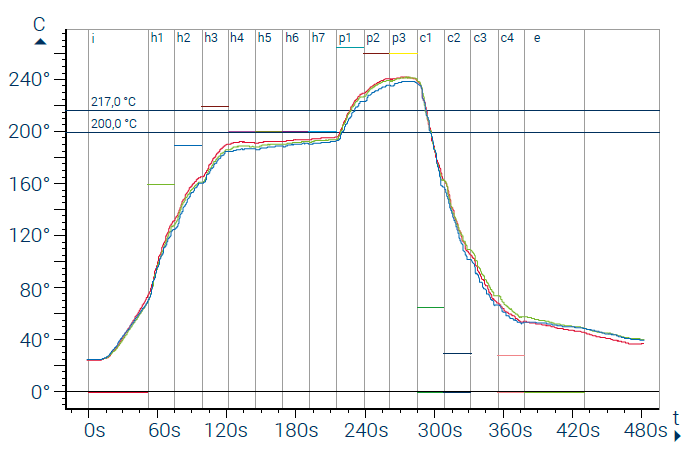

Linear profile

With a linear profile, the component is not heated in a stepped

manner during soldering, in fact it is heated along an identical

linear temperature gradient. Linear profiles can reduce cycle times

and can help to reduce soldering errors such as tombstoning

Heating System

<Separately adjustable heating zones

<Reproducible temperature profile

<Outstanding process stability with the smallest possible ΔT

<Homogenous heat input over the entire PCB thanks to specially designed nozzles

<Low maintenance effort

| I.C.T-LV733 | I.C.T-LV733N | |

| DIMENSIONS AND WEIGHTS | ||

| Dimensions | 7000*1430*1530mm | |

| Required area | 10.05m2 | |

| Weight | ca. 3200 kg | ca. 3300 kg |

| Load per unit area 400 kg/m2 | 400 kg/m2 | |

| PROCESS CHAMBER HEATING | ||

| Length of heating zones | 3730mm | |

| Quantity of preheating zones | 7 | |

| Length of preheating zones | 2675mm | |

| Quantity of peak zones | 3 | |

| Warm up time | ca. 20 min | |

| VACUUM ZONE | ||

| Vacuum maximum pressure | 0.1-12kpa | |

| Vacuum pump flow | 1500/min | |

| Pressure relief time | ≦10S | |

| Product time | ≧40S | |

| COOLING ZONE | ||

| Quantity of cooling zones | 3(top 3/bottom 3) | |

| Length of cooling zones | 1460mm | |

| CONVEYOR | ||

| Transport Level | 900 ±20 mm | |

| PCB Width | L500 - W400mm | |

| Conveyor control | 3-stage, independent control | |

| Conveyor Number | 1 | |

| Adjustable conveyor speed | 300 - 1800 mm/min | |

| INTERFACES | ||

| Type | SMEMA | |

| Voltage supply | 5-Wire System 3P,N,PE 380 VAC ± 5 % 50 Hz Other voltages upon request | |

| Connected load | 65KW | |

| Operating capacity | 16 KW | |

| As the operating efficiency depends on the settings of the process parameters, the values reached actually can differ from the values indicated here. | ||

I.C.T LV Series Vacuum reflow oven unparalleled heating performance and temperature control system meets the requirements of various soldering processes, LV Series Vacuum Reflow Oven is high-end reflow products committed to keeping up with market demand to enhance customers competitiveness.Its new design concept fully meets the needs of increasingly diverse processes, And considering the future direction of the industry, entirely suitable for communications, automotive electronics, home appliances, computers and other consumer electronic products .

1.Control System: PC + Siemens PLC control system,accurate temperature control and more stable,ensures temperature stability rate to be

more than 99.99%.

2.Vacuum system:PCB directly enters the vacuum unit from soldering area. Start the vacuum process to reduce the vacuum pressure to

100mbar-5mbar. The internal gas such as pores and cavities overflows from the molten solder joint, which can reduce the void rate to less

than 2%.

3.Hot air system: first-class heating module, the best temperature zone interval design makes optimum temperature uniformity and repeat.The

effective utilization and thermal compensation efficiency,it needs less than 20 minutes from temperature control accuracy ± 1 ℃ ambient

temperature to a temperature stabilization .

4.Monitoring Software:Windows interface, traditional and simplified Chinese and English online free switch, and operator password

management, easy to operate.Operation records, temperature curve measurement and analysis functions, virtual simulation, fault

self-diagnosis, process monitoring, automatic generate and save process control documents, substrate transport dynamic display.

From zero to 240 °C due to optimized heat transfer

Each product has its own requirements in the manufacturing process. Optimized heat transfer over the entire soldering process is the basis for

best possible results.

The LV-Series offers flexibly controllable preheating zones within which your PCB is preheated and prepared for the actual soldering process.

The individual zones can be controlled independently of each other via fan frequency, and assure best possible processes.

The LV-Series is equipped with special nozzle sheets for optimized heat transfer by means of uniform air flow over the PCBs. Flow speeds in the

upper and lower heat zones can be separately controlled, assuring that your PCB is heated up.

Saddle profile

The component is brought to a temperature of at least 240 °C for

soldering. Using a saddle profile the board is gradually heated in line

with pre-defined, individual temperature ranges. Even components

with differing thermal masses are heated homogeneously and

temperature differences minimised.

Linear profile

With a linear profile, the component is not heated in a stepped

manner during soldering, in fact it is heated along an identical

linear temperature gradient. Linear profiles can reduce cycle times

and can help to reduce soldering errors such as tombstoning

Heating System

<Separately adjustable heating zones

<Reproducible temperature profile

<Outstanding process stability with the smallest possible ΔT

<Homogenous heat input over the entire PCB thanks to specially designed nozzles

<Low maintenance effort

| I.C.T-LV733 | I.C.T-LV733N | |

| DIMENSIONS AND WEIGHTS | ||

| Dimensions | 7000*1430*1530mm | |

| Required area | 10.05m2 | |

| Weight | ca. 3200 kg | ca. 3300 kg |

| Load per unit area 400 kg/m2 | 400 kg/m2 | |

| PROCESS CHAMBER HEATING | ||

| Length of heating zones | 3730mm | |

| Quantity of preheating zones | 7 | |

| Length of preheating zones | 2675mm | |

| Quantity of peak zones | 3 | |

| Warm up time | ca. 20 min | |

| VACUUM ZONE | ||

| Vacuum maximum pressure | 0.1-12kpa | |

| Vacuum pump flow | 1500/min | |

| Pressure relief time | ≦10S | |

| Product time | ≧40S | |

| COOLING ZONE | ||

| Quantity of cooling zones | 3(top 3/bottom 3) | |

| Length of cooling zones | 1460mm | |

| CONVEYOR | ||

| Transport Level | 900 ±20 mm | |

| PCB Width | L500 - W400mm | |

| Conveyor control | 3-stage, independent control | |

| Conveyor Number | 1 | |

| Adjustable conveyor speed | 300 - 1800 mm/min | |

| INTERFACES | ||

| Type | SMEMA | |

| Voltage supply | 5-Wire System 3P,N,PE 380 VAC ± 5 % 50 Hz Other voltages upon request | |

| Connected load | 65KW | |

| Operating capacity | 16 KW | |

| As the operating efficiency depends on the settings of the process parameters, the values reached actually can differ from the values indicated here. | ||

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT