I.C.T-P6

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Overview

Introduce:

Introduce: 1. Using linear guide-ways,matching motor drive speed , ensure the printing stability and precision.

2. Blade pressure and printing speed is adjustable,precision pressure gauge, speed controller display.

3. Suspension blade system makes printing more evenly.

4. Modular universal bench, thimble random placement , easy conversion.

5. With alignment device for PCB board and frame.

6. Work with both single-sided and double-sided PCB boards.

7. Steel frame arms can be adjusted for different size ranges from 370 * 470mm to 1500 * 350mm .

8. Auto printing , stable and efficient printing quality.

Platform system

The pin and support block shall be suitable for different one-sided

and double-sided PCB, and the pin of different sizes shall be suitable

for different PCB holes. operation simple, the positioning is

accurate, and the fixed position is flexible and adjustable.

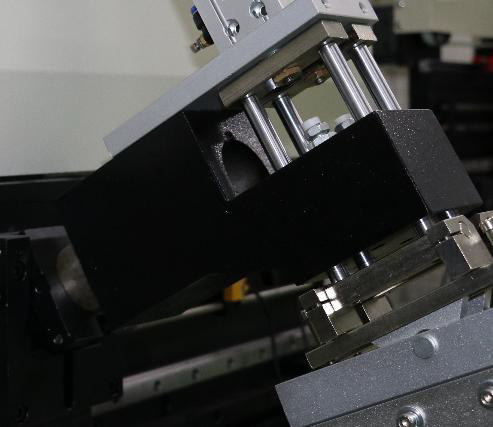

Print system

Direct connection squeegee structure.The squeegee is

independently controlled by two high-precision cylinder to ensure

accurate and stable pressure.The double slide positioning rails

ensure the accuracy and stability of the squeegee.

| Model | P3 | P6 | P12 | P15 |

| Accuracy | +/- 0.05mm | +/- 0.05mm | +/- 0.05mm | +/- 0.05mm |

| PCB Size | 300 x 350 mm | 600 x 350 mm | 1200 x 350 mm | 1500 x 350 mm |

| Platform size | 320 x 400 mm | 700 x 400 mm | 1350 x 400 mm | 1650 x 400 mm |

| Stencil Size(mm) | 370*470-550*650 | 370*470-550*650 | 370*470-1500*650 | 370*470-1750*650 |

| PCB Thickness | 0.2 - 6 mm | 0.2 - 6 mm | 0.2 - 6 mm | 0.2 - 6 mm |

| Stencil Positioning | Manual | Manual | Manual | Manual |

| Cycle Time | < 10 Sec. | < 10 Sec. | < 12 Sec. | < 12 Sec. |

| Power Consumption | 200 W | 200 W | 220 W | 220 W |

| Power Supply | 1 -PH, 220VAC 50/60HZ | 1 -PH, 220VAC 50/60HZ | 1 -PH, 220VAC 50/60HZ | 1 -PH, 220VAC 50/60HZ |

| Air Pressure | 4.5-6 kg/cm | 4.5-6 kg/cm | 4.5-6 kg/cm | 4.5-6 kg/cm |

| Squeegee Speed | 0-200mm/sec | 0-1200mm/sec | 0-200mm/sec | 0-200mm/sec |

| Dimension | 850x750x1650 mm | 1050x750x1650 mm | 1660x750x1650 mm | 2100x750x1650 mm |

| Weight | 280 Kg | 300 Kg | 356 Kg | 430 Kg |

| Squeegee Length | 250mm | 250mm | 250mm | 250mm |

| Platform Height | 950mm | 950mm | 950mm | 950mm |

| Option: Special size can be customized | ||||

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Overview

Introduce:

Introduce: 1. Using linear guide-ways,matching motor drive speed , ensure the printing stability and precision.

2. Blade pressure and printing speed is adjustable,precision pressure gauge, speed controller display.

3. Suspension blade system makes printing more evenly.

4. Modular universal bench, thimble random placement , easy conversion.

5. With alignment device for PCB board and frame.

6. Work with both single-sided and double-sided PCB boards.

7. Steel frame arms can be adjusted for different size ranges from 370 * 470mm to 1500 * 350mm .

8. Auto printing , stable and efficient printing quality.

Platform system

The pin and support block shall be suitable for different one-sided

and double-sided PCB, and the pin of different sizes shall be suitable

for different PCB holes. operation simple, the positioning is

accurate, and the fixed position is flexible and adjustable.

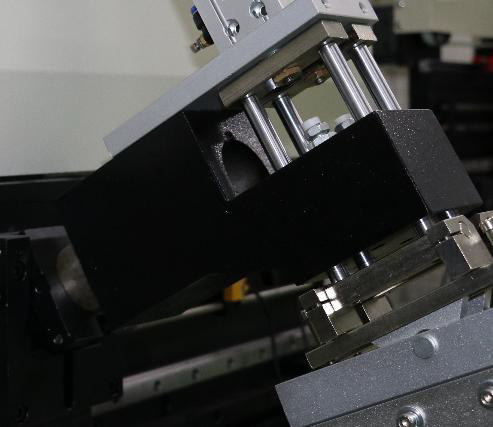

Print system

Direct connection squeegee structure.The squeegee is

independently controlled by two high-precision cylinder to ensure

accurate and stable pressure.The double slide positioning rails

ensure the accuracy and stability of the squeegee.

| Model | P3 | P6 | P12 | P15 |

| Accuracy | +/- 0.05mm | +/- 0.05mm | +/- 0.05mm | +/- 0.05mm |

| PCB Size | 300 x 350 mm | 600 x 350 mm | 1200 x 350 mm | 1500 x 350 mm |

| Platform size | 320 x 400 mm | 700 x 400 mm | 1350 x 400 mm | 1650 x 400 mm |

| Stencil Size(mm) | 370*470-550*650 | 370*470-550*650 | 370*470-1500*650 | 370*470-1750*650 |

| PCB Thickness | 0.2 - 6 mm | 0.2 - 6 mm | 0.2 - 6 mm | 0.2 - 6 mm |

| Stencil Positioning | Manual | Manual | Manual | Manual |

| Cycle Time | < 10 Sec. | < 10 Sec. | < 12 Sec. | < 12 Sec. |

| Power Consumption | 200 W | 200 W | 220 W | 220 W |

| Power Supply | 1 -PH, 220VAC 50/60HZ | 1 -PH, 220VAC 50/60HZ | 1 -PH, 220VAC 50/60HZ | 1 -PH, 220VAC 50/60HZ |

| Air Pressure | 4.5-6 kg/cm | 4.5-6 kg/cm | 4.5-6 kg/cm | 4.5-6 kg/cm |

| Squeegee Speed | 0-200mm/sec | 0-1200mm/sec | 0-200mm/sec | 0-200mm/sec |

| Dimension | 850x750x1650 mm | 1050x750x1650 mm | 1660x750x1650 mm | 2100x750x1650 mm |

| Weight | 280 Kg | 300 Kg | 356 Kg | 430 Kg |

| Squeegee Length | 250mm | 250mm | 250mm | 250mm |

| Platform Height | 950mm | 950mm | 950mm | 950mm |

| Option: Special size can be customized | ||||

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

FAQ:

Q: What is a solder paste printing machine?

A: A solder paste printing machine is an essential component in the Surface Mount Technology (SMT) assembly process. It accurately deposits solder paste onto printed circuit boards (PCBs) through a stencil. This is a critical step for precise placement of surface-mount components during PCB assembly.

Q: What speed is solder paste printing?

A: Solder paste printing speed varies depending on the specific machine and process. Typical speeds can range from 30 to 200 millimeters per second (mm/s), but it can be adjusted to meet the requirements of the PCB and solder paste being used.

Q: What are the different types of solder paste printing?

A: Solder paste printing methods include "screen printing" and "stencil printing." Screen printing uses a mesh screen to apply solder paste, while stencil printing uses a precisely crafted stencil to deposit solder paste onto PCBs. Stencil printing is more common in SMT assembly due to its higher precision.

Q: What is the effect of the squeegee blade on solder paste print quality?

A: The squeegee blade in a solder paste printing machine plays a crucial role in determining print quality. Factors like blade material, angle, and pressure influence the solder paste's deposition. Proper blade setup ensures uniform paste thickness, which is essential for accurate component placement and reliable solder joints.

These succinct answers can be placed in your product's details page FAQ section to enhance your website's Google search visibility.

FAQ:

Q: What is a solder paste printing machine?

A: A solder paste printing machine is an essential component in the Surface Mount Technology (SMT) assembly process. It accurately deposits solder paste onto printed circuit boards (PCBs) through a stencil. This is a critical step for precise placement of surface-mount components during PCB assembly.

Q: What speed is solder paste printing?

A: Solder paste printing speed varies depending on the specific machine and process. Typical speeds can range from 30 to 200 millimeters per second (mm/s), but it can be adjusted to meet the requirements of the PCB and solder paste being used.

Q: What are the different types of solder paste printing?

A: Solder paste printing methods include "screen printing" and "stencil printing." Screen printing uses a mesh screen to apply solder paste, while stencil printing uses a precisely crafted stencil to deposit solder paste onto PCBs. Stencil printing is more common in SMT assembly due to its higher precision.

Q: What is the effect of the squeegee blade on solder paste print quality?

A: The squeegee blade in a solder paste printing machine plays a crucial role in determining print quality. Factors like blade material, angle, and pressure influence the solder paste's deposition. Proper blade setup ensures uniform paste thickness, which is essential for accurate component placement and reliable solder joints.

These succinct answers can be placed in your product's details page FAQ section to enhance your website's Google search visibility.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT