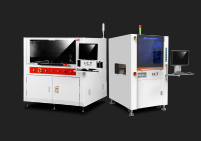

As a SMT Machine manufacturer focused on providing SMT (Surface Mount Technology) and DIP (Dual In-line package) turnkey solutions, we understand the importance and challenges of the semiconductor industry, and we know that you have deep concerns about the use of SMT technology in the semiconductor industry.

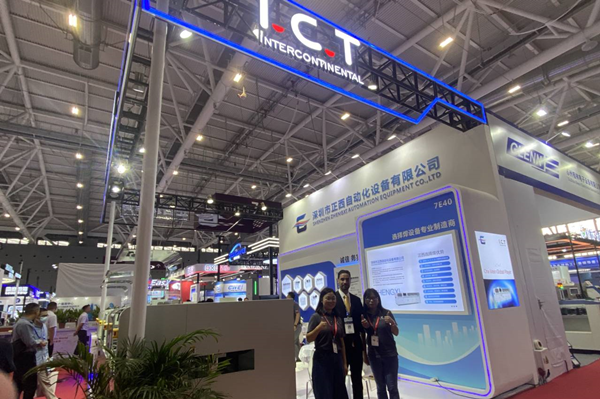

In this article, we will show you the important applications of SMT technology in the semiconductor field, as well as the strengths and successful SMT experience of our factories, so that you can have a deeper and more comprehensive understanding of us (I.C.T), and believe that we can bring more possibilities to your production.

Types of Semiconductor Products, some of the common ones include:

1. Integrated circuit (IC): IC is a device that integrates multiple electronic components on one chip, and is widely used in various fields such as computers, mobile phones, and automotive electronics.

2. Diodes and transistors: As basic semiconductor components, diodes are used in rectification and switching circuits, and transistors are used to amplify and control current.

3. Sensors: Semiconductor sensors are used to detect and measure environmental parameters such as temperature, humidity, and pressure, and are used in automatic control and smart devices.

4. Power devices: Power semiconductor devices are used in the field of power electronics, such as converters, inverters and other high-power circuit applications.

The Core Value of SMT Technology in Semiconductor Production:

1. Excellent process advantage: With its high-precision assembly and placement process, SMT technology accurately connects micro-packaged integrated circuits, transistors and other components on the chip to ensure the stability and reliability of product quality.

2. Efficient production capacity: With the help of Automated Production Lines, SMT technology realizes seamless connection of mounting, soldering and testing, which greatly improves the production efficiency and provides strong support for you to quickly respond to market demands.

3. Multi-component integration: Our team of engineers conducts in-depth research on the characteristics of different components and packages to optimize the placement process, which helps you achieve high integration of multiple components on a small packaged chip, providing more possibilities for your product performance.

4. Stable Quality Assurance: SMT production equipment is equipped with advanced quality monitoring system, which monitors every step of the production process to ensure that the products meet international standards, providing you with stable quality assurance.

We have successfully applied SMT technology to semiconductor manufacturing and achieved remarkable results. Based on more than 20 years of SMT experienced technical team, advanced equipment and efficient service, we provide customers with the best complete line solutions to ensure the smooth production of customers and also get the industry's recognition.

As your Reliable Dearest partner, we look forward to working with you to create customized and optimized SMT and DIP line solutions to help you achieve greater success in the semiconductor industry!

In May 2023, we successfully delivered a semiconductor production line to our partner in Malaysia.

Semiconductor SMT Case Video FYI:

English

English