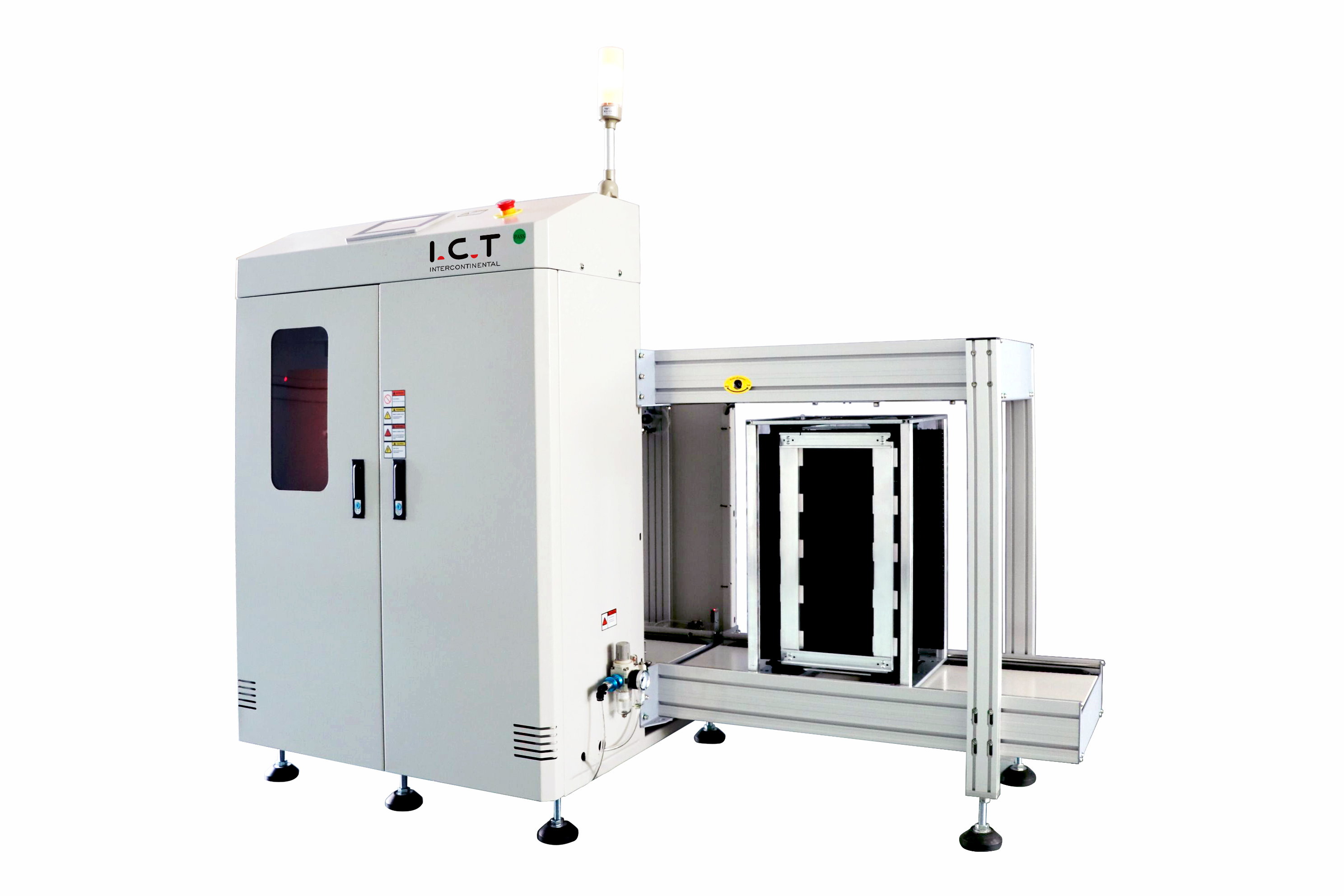

VC-M

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

The SMT Automatic Vacuum and Magazine Loader is a versatile solution designed to streamline PCB loading processes in modern electronics manufacturing. It combines vacuum-based loading for bare or delicate PCBs with magazine-based loading for batch operations. By integrating advanced PLC controls, a user-friendly touchscreen interface, and precise pneumatic or servo-driven mechanisms, this loader ensures fast, accurate, and damage-free PCB handling. Its compact footprint, robust steel/aluminum frame, and SMEMA compatibility allow for easy integration into existing SMT lines, improving throughput while reducing manual labor and handling errors.

High quality PCB loader unloader, SMT magazine loader, mini cyclic Loader, mini size SMT loader, 90 degree SMT magazine loader unloader, SMT Automatic Vacuum and Magazine Loader, NG/ OK unloader, for SMT SMD Production Line.

Automatic Vacuum and Magazine Loader

Modular design, optional assembly as per client's requipment.

Rugged steel design, improves equipment stability.

Top & Bottom pneumatic clamps to secure magazine rack.

Soft touch LED control panel or touch screen can be selected.

| Model | VC-M | VC-L | VC-LL | VC-XL |

| Dimension(mm) | 1800*865*1250 | 2220*945*1250 | 2450*1110*1250 | 2450*1250*1250 |

| PCB Size(mm) | 50*50-330*250 | 50*50-445*330 | 50*50-530*390 | 50*50-530*460 |

| Rack Size(mm) | 355*320*563 | 460*400*563 | 535*460*570 | 535*530*570 |

| Control System | PLC | |||

| Power Supply | 1 PH AC 220V 50/60Hz (Option:110V to 380V) | |||

| Weight | 220 Kg | 260 Kg | 300 Kg | 340 Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

What is the difference between vacuum loading and magazine loading?

Vacuum loading uses suction to pick and place individual PCBs, making it ideal for delicate or bare boards. Magazine loading, on the other hand, handles multiple boards stacked in a magazine, which is more efficient for batch processing. Both methods can be integrated into one machine to accommodate different production needs.

How do I determine if my PCBs are compatible with the loader`s vacuum system?

Compatibility depends on factors like PCB size, weight, and surface finish. Most loaders specify minimum and maximum dimensions/weights. Ensure your board has enough flat surface area for the vacuum nozzle to grip securely, and check the loader`s specifications for suction pressure limits.

Is the SMT Automatic Vacuum and Magazine Loader SMEMA compatible?

Yes. Most modern loaders are designed with SMEMA (Surface Mount Equipment Manufacturers Association) standards, ensuring seamless communication with other SMT equipment such as conveyors, printers, and pick-and-place machines.

What kind of maintenance does the loader require?

Routine maintenance typically includes cleaning the vacuum nozzles, checking the pneumatic system for air leaks, lubricating moving parts, and updating PLC software when needed. Regular maintenance helps maintain accuracy, prolong equipment life, and prevent unexpected downtime.

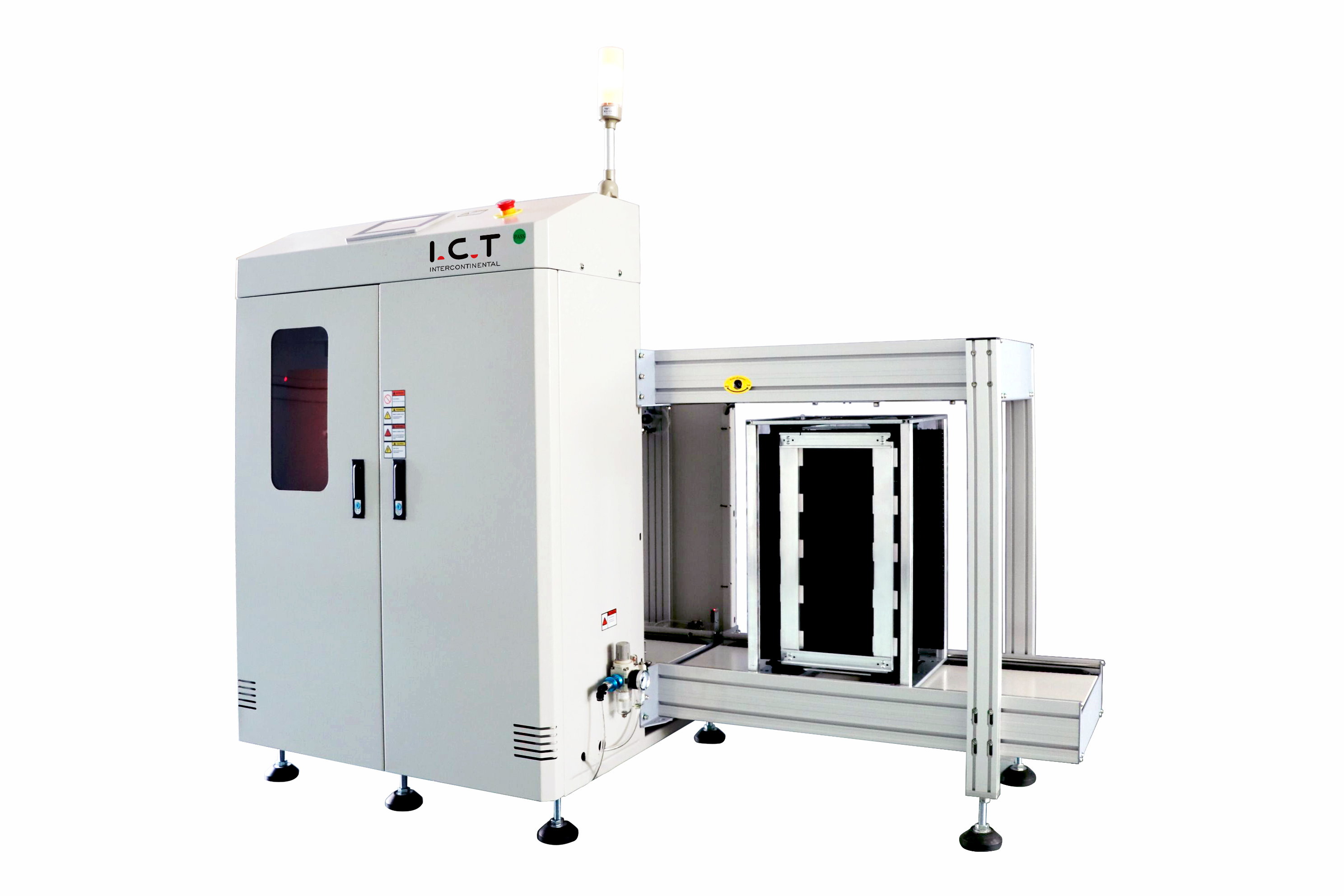

The SMT Automatic Vacuum and Magazine Loader is a versatile solution designed to streamline PCB loading processes in modern electronics manufacturing. It combines vacuum-based loading for bare or delicate PCBs with magazine-based loading for batch operations. By integrating advanced PLC controls, a user-friendly touchscreen interface, and precise pneumatic or servo-driven mechanisms, this loader ensures fast, accurate, and damage-free PCB handling. Its compact footprint, robust steel/aluminum frame, and SMEMA compatibility allow for easy integration into existing SMT lines, improving throughput while reducing manual labor and handling errors.

High quality PCB loader unloader, SMT magazine loader, mini cyclic Loader, mini size SMT loader, 90 degree SMT magazine loader unloader, SMT Automatic Vacuum and Magazine Loader, NG/ OK unloader, for SMT SMD Production Line.

Automatic Vacuum and Magazine Loader

Modular design, optional assembly as per client's requipment.

Rugged steel design, improves equipment stability.

Top & Bottom pneumatic clamps to secure magazine rack.

Soft touch LED control panel or touch screen can be selected.

| Model | VC-M | VC-L | VC-LL | VC-XL |

| Dimension(mm) | 1800*865*1250 | 2220*945*1250 | 2450*1110*1250 | 2450*1250*1250 |

| PCB Size(mm) | 50*50-330*250 | 50*50-445*330 | 50*50-530*390 | 50*50-530*460 |

| Rack Size(mm) | 355*320*563 | 460*400*563 | 535*460*570 | 535*530*570 |

| Control System | PLC | |||

| Power Supply | 1 PH AC 220V 50/60Hz (Option:110V to 380V) | |||

| Weight | 220 Kg | 260 Kg | 300 Kg | 340 Kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

What is the difference between vacuum loading and magazine loading?

Vacuum loading uses suction to pick and place individual PCBs, making it ideal for delicate or bare boards. Magazine loading, on the other hand, handles multiple boards stacked in a magazine, which is more efficient for batch processing. Both methods can be integrated into one machine to accommodate different production needs.

How do I determine if my PCBs are compatible with the loader`s vacuum system?

Compatibility depends on factors like PCB size, weight, and surface finish. Most loaders specify minimum and maximum dimensions/weights. Ensure your board has enough flat surface area for the vacuum nozzle to grip securely, and check the loader`s specifications for suction pressure limits.

Is the SMT Automatic Vacuum and Magazine Loader SMEMA compatible?

Yes. Most modern loaders are designed with SMEMA (Surface Mount Equipment Manufacturers Association) standards, ensuring seamless communication with other SMT equipment such as conveyors, printers, and pick-and-place machines.

What kind of maintenance does the loader require?

Routine maintenance typically includes cleaning the vacuum nozzles, checking the pneumatic system for air leaks, lubricating moving parts, and updating PLC software when needed. Regular maintenance helps maintain accuracy, prolong equipment life, and prevent unexpected downtime.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT