X-9200

I.C.T

X-ray inspection machine

| Availability: | |

|---|---|

| Quantity: | |

The X-9200 is designed to provide high-resolution X-ray imaging for the electronics industry. This versatile system is effective for many applications in the PCB manufacturing process. It can be used to detect integrated circuit chips and semiconductors, including BGA, IGBT, flip chip and PCBA component welding, LED, IC packaging and other industries for high-precision testing.

1. CNC program: automatic batch detection of different positions of samples;

2. Array function: automatic batch detection of samples with fixed positions and the same spacing;

3. Length and width measurement: measure the length and width of part of the detection area;

4. Visual navigation interface: precise positioning, X-Y to achieve precise displacement of the joystick;

5. Simulate color: better observe the inspection image;

6. Bubble measurement: One-key measurement of bubble size, void rate, and tin climbing height;

7. Automatically ON/OFF X-RAY light tube to detect samples in batches;

8. Equipped with Japanese X-RAY light tube, the detection accuracy can reach 1um;

9. High-resolution digital X-RAY flat panel;

10. The stage can accommodate a large number of samples of various sizes;

11. Optional 360° rotation of the stage to detect samples;

12. Allow 60° tilt observation;

13. Windows navigation, convenient target tracking;

14. Ergonomic design, friendly man-machine interface;

15. High safety, with EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray.

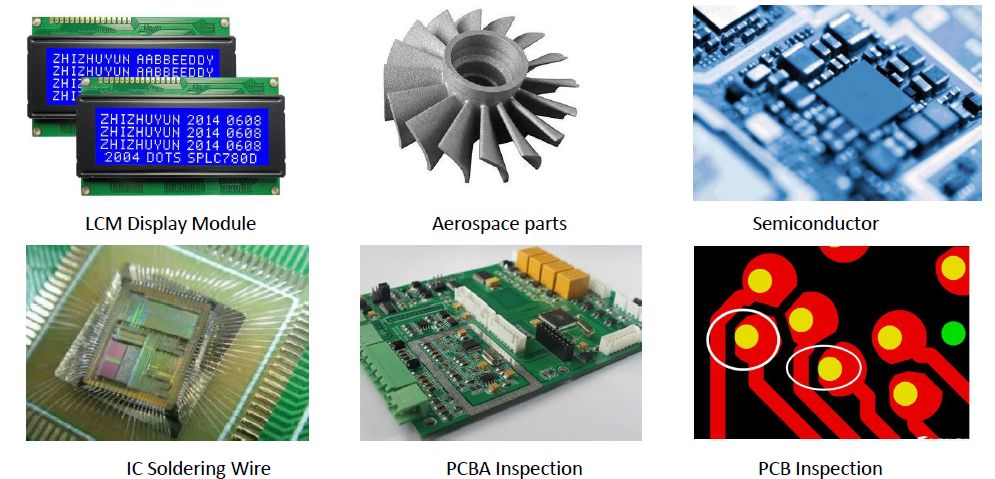

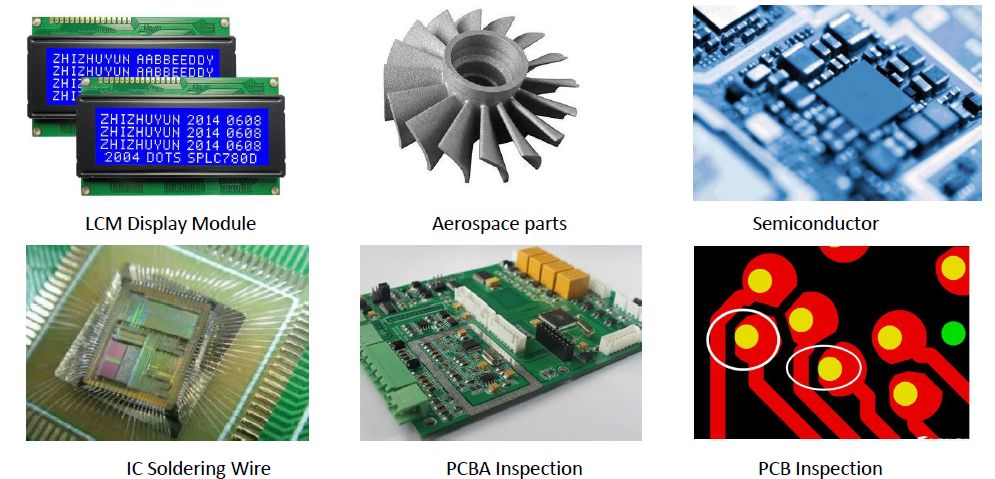

SMT, BGA, CSP, LGA, POP, SIP, Flip Chip, LED, IGBT, Semiconductor, Packaging components, Battery, Electronic components, Automotive parts,

LCM display module, other special industries.

| Item | Model | I.C.T X-9200 |

| X-Ray Tube | Type | Transmissive Light Tube |

| Voltage | 100kv/110kv, 200μA/300μA | |

| Spatial resolution | 1μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 76μm | |

| A/D conversion quantized density value | 16bit | |

| Resolution | 1648*1644px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 2500x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1800W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 690*685mm |

| Max. Inspection area | 670*665mm | |

| Max. Loading weight | ≤20kg | |

| Platform rotation angle | 60° | |

| Dimension | 1510*1770*1850mm | |

| Weight | 1800kg | |

| Platform movement | Manual/Auto |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

The X-9200 is designed to provide high-resolution X-ray imaging for the electronics industry. This versatile system is effective for many applications in the PCB manufacturing process. It can be used to detect integrated circuit chips and semiconductors, including BGA, IGBT, flip chip and PCBA component welding, LED, IC packaging and other industries for high-precision testing.

1. CNC program: automatic batch detection of different positions of samples;

2. Array function: automatic batch detection of samples with fixed positions and the same spacing;

3. Length and width measurement: measure the length and width of part of the detection area;

4. Visual navigation interface: precise positioning, X-Y to achieve precise displacement of the joystick;

5. Simulate color: better observe the inspection image;

6. Bubble measurement: One-key measurement of bubble size, void rate, and tin climbing height;

7. Automatically ON/OFF X-RAY light tube to detect samples in batches;

8. Equipped with Japanese X-RAY light tube, the detection accuracy can reach 1um;

9. High-resolution digital X-RAY flat panel;

10. The stage can accommodate a large number of samples of various sizes;

11. Optional 360° rotation of the stage to detect samples;

12. Allow 60° tilt observation;

13. Windows navigation, convenient target tracking;

14. Ergonomic design, friendly man-machine interface;

15. High safety, with EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray.

SMT, BGA, CSP, LGA, POP, SIP, Flip Chip, LED, IGBT, Semiconductor, Packaging components, Battery, Electronic components, Automotive parts,

LCM display module, other special industries.

| Item | Model | I.C.T X-9200 |

| X-Ray Tube | Type | Transmissive Light Tube |

| Voltage | 100kv/110kv, 200μA/300μA | |

| Spatial resolution | 1μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 76μm | |

| A/D conversion quantized density value | 16bit | |

| Resolution | 1648*1644px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 2500x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1800W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 690*685mm |

| Max. Inspection area | 670*665mm | |

| Max. Loading weight | ≤20kg | |

| Platform rotation angle | 60° | |

| Dimension | 1510*1770*1850mm | |

| Weight | 1800kg | |

| Platform movement | Manual/Auto |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT