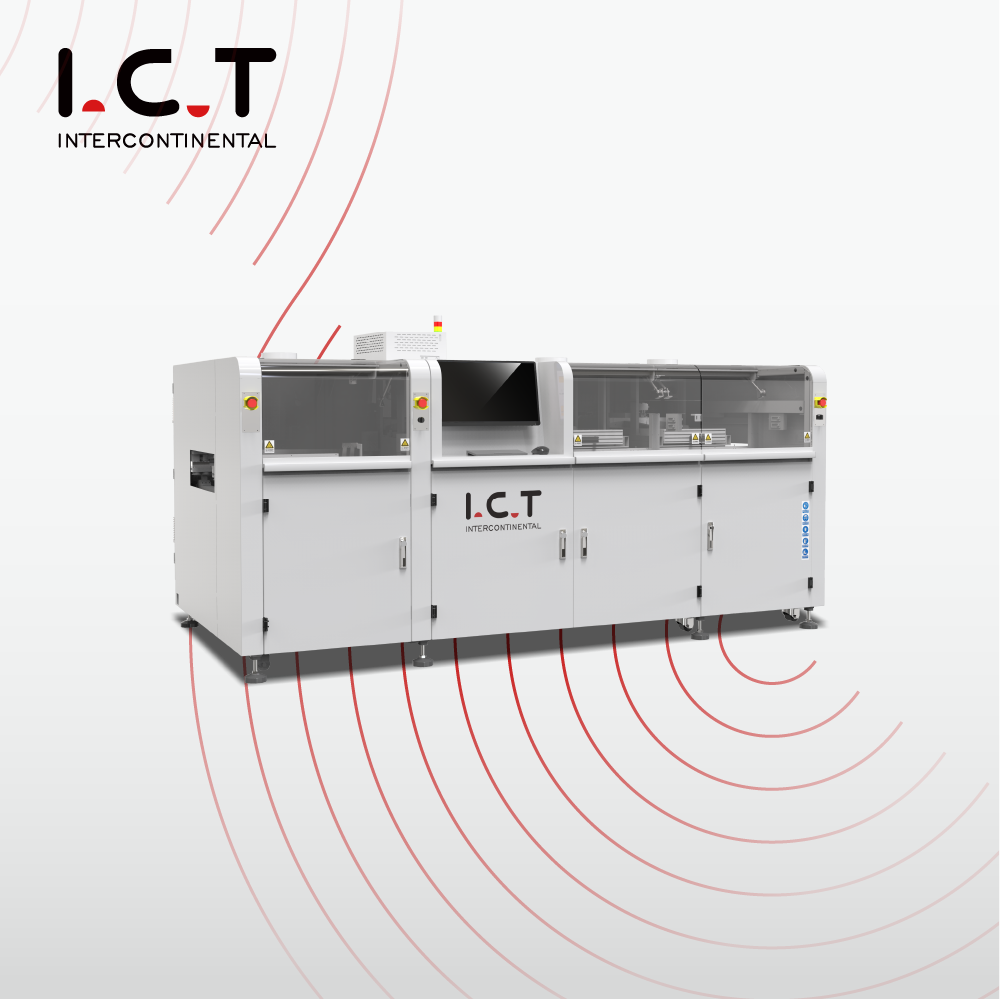

New Promotion Selective Wave Soldering Machine Automatic SS550 I.C.T Hot Sale

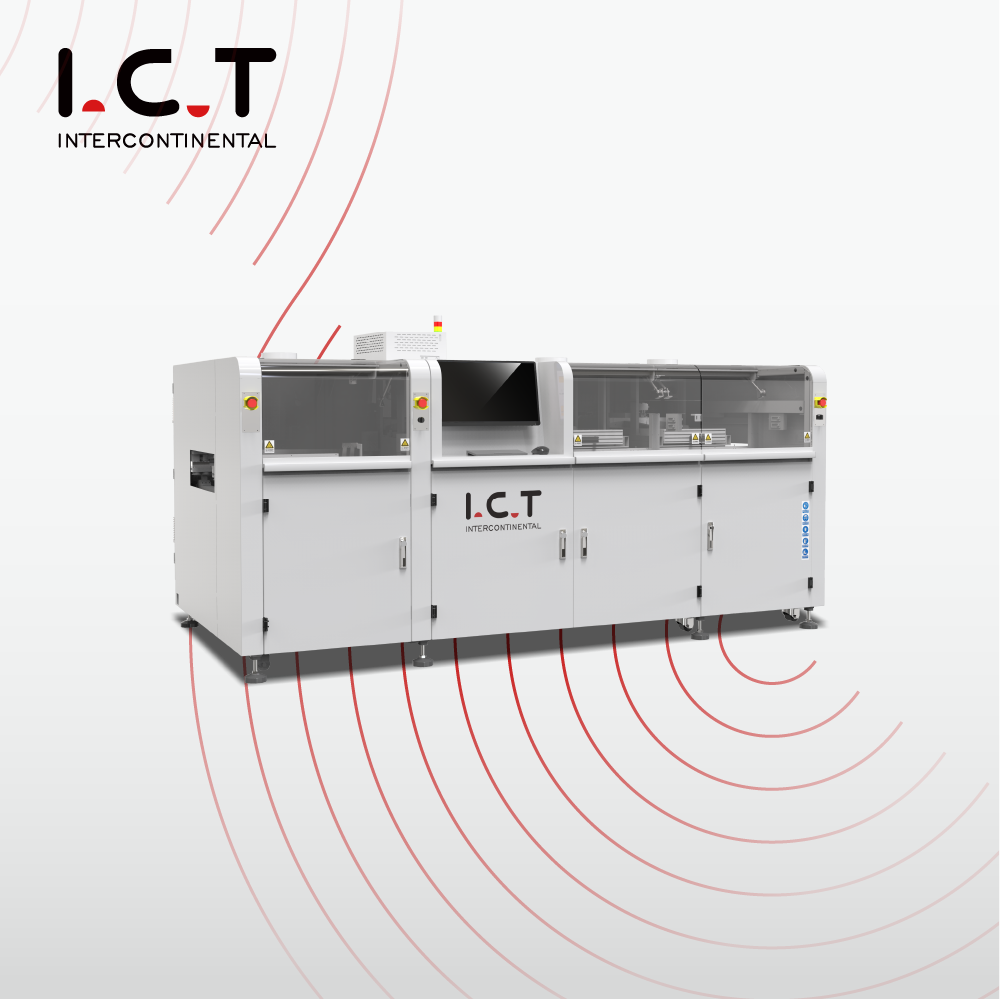

I.C.T-SS550P2 is an advanced in-line 3 tin bath selective wave soldering machine at factory price. Selective wave soldering is a special form of wave soldering designed to meet the developing needs of through-hole component soldering.The I.C.T SS540/550 in-line selective wave soldering is a high performance machine developed and assembled in China.

I.C.T SS550P1/ SS550P2 online selective wave soldering is a high performance equipment developed and assembled in China.

I.C.T-SS550P1

I.C.T-SS550P2

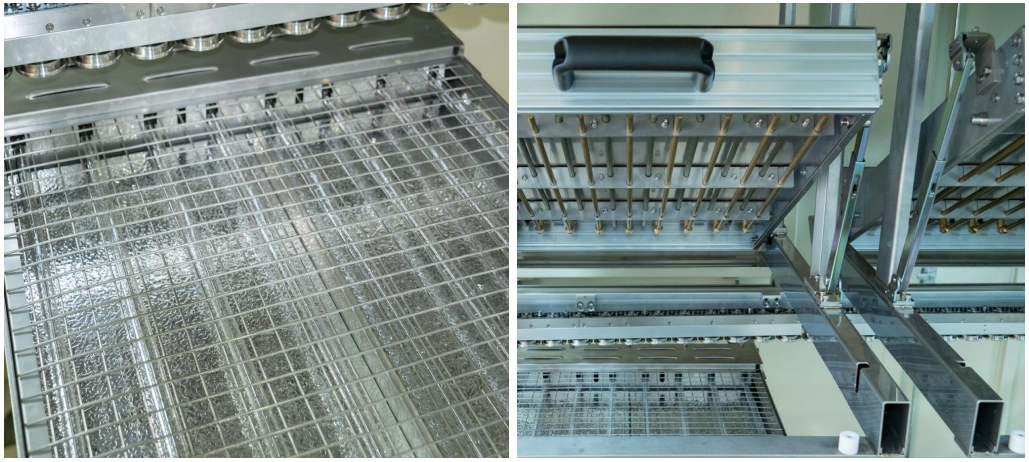

Solder pot made of stainless steel with anti-corrosion coating. Titanium alloy available upon request. Cast iron heater for robust and fast heat-up. N2 online heating system ensures perfect wetting of the solder and reduces solder dross. Stainless steel roller on conveyor ensures wearability.SMEMA inline conveyor features modular design for flexible line configuration. Fully computerized control. All parameters can be set on the computer and saved in the PCB menu, including travel path, soldering temperature, flux type, solder type, N2 temperature, etc., for excellent traceability and easy reproducibility of soldering quality.

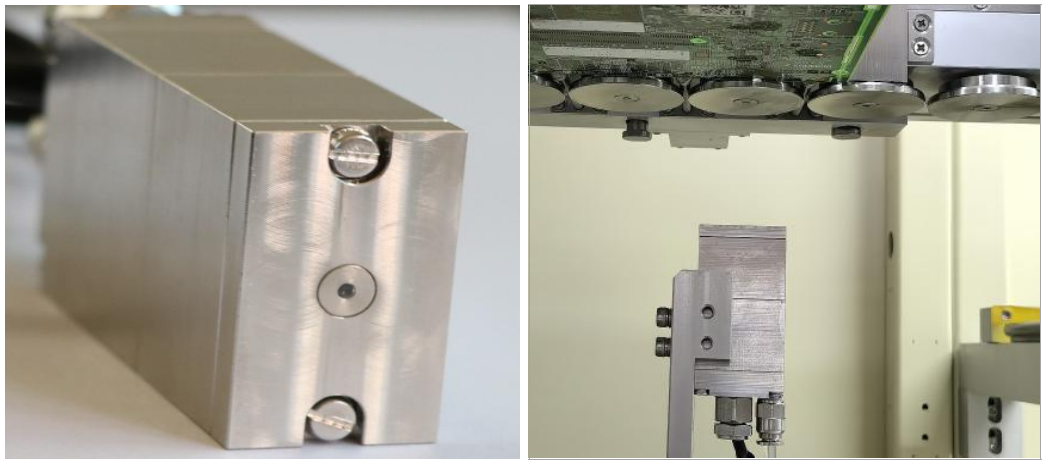

Features 1 Flux system:

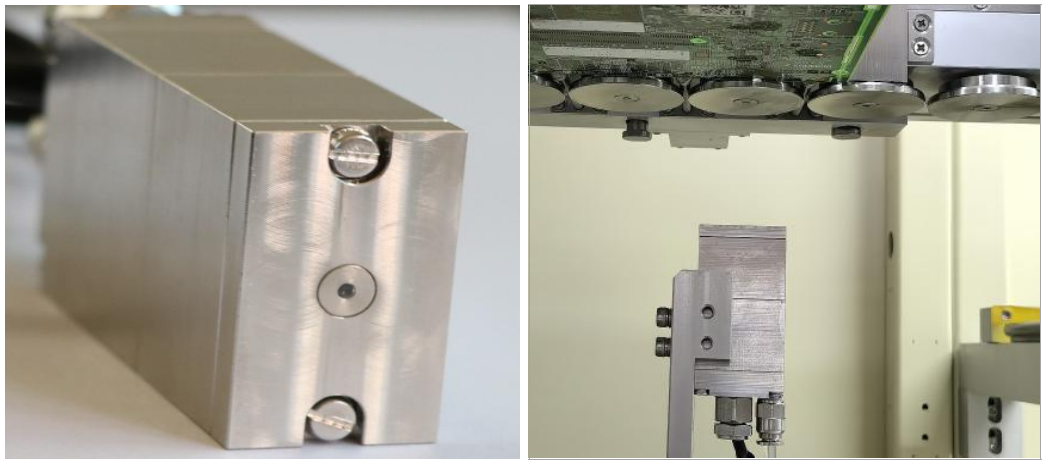

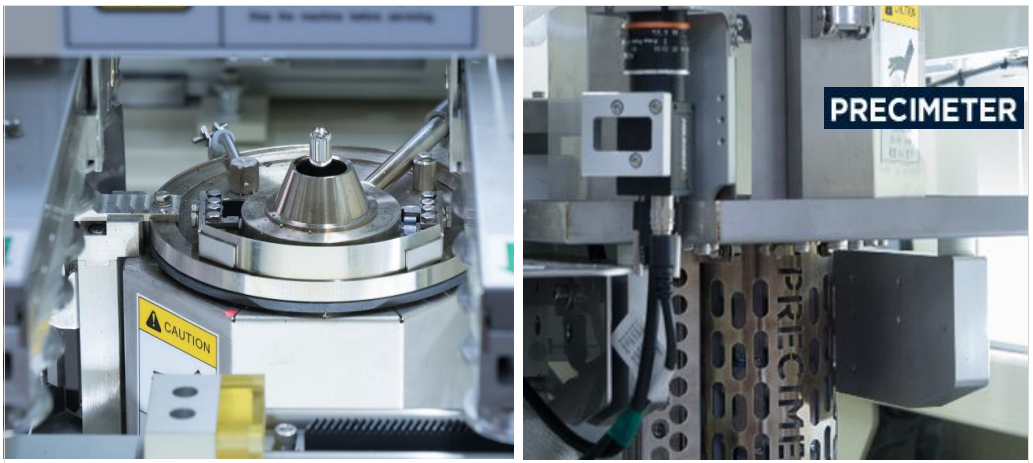

1. German high-frequency pulse injection valve to get precious fluxing result with small flux dot, flux solid content should be less than 10%. The flux nozzle jam detection function is optional.

2. It is configuration with tray under the jet valve to catch the flux residue for easy maintenance.

3. The nozzle is mounted on the XY platform, the accuracy of repetition and positioning can reach 0.02mm.

Features 2 Preheat system:

1. The machine is equipped with bottom IR preheating as standard, and the preheating area can be set; top hot air preheating, infrared heating Conduction is efficient and stable.

2. Design structure for maximizing preheating area.

3. All round high temperature cotton design to ensure temperature stability.

4. Heat-generating and heat-conducting parts and motors adopt top brands.

5. Maintenance plug-in design, tool-free maintenance mode.

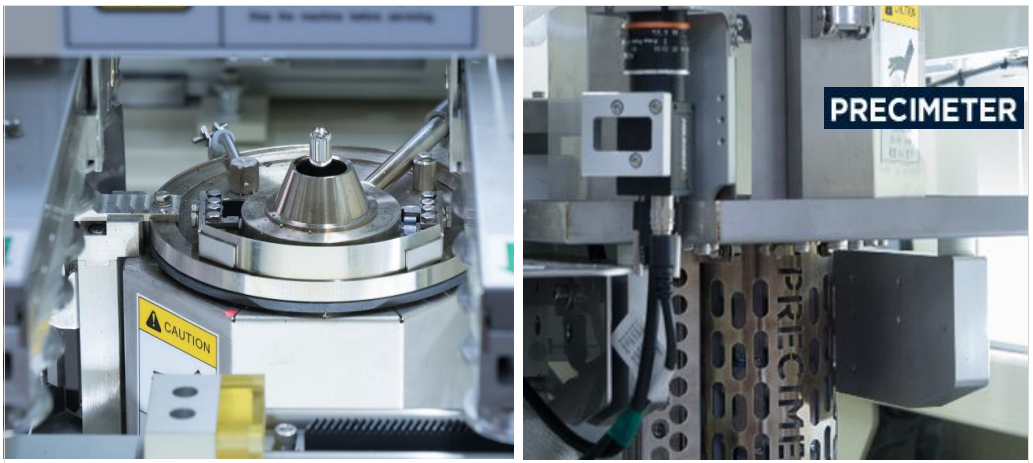

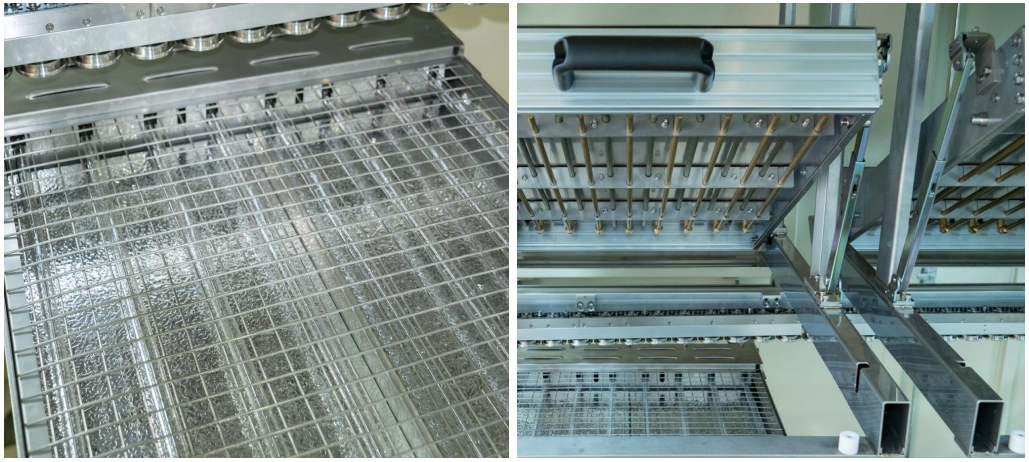

Features 3 Soldering system:

1. Electromagnetic pump coil adopts Sweden “PRECIMETER” brand to ensure the stability and reliability of the peak.

2. Solder temperature, N2 temperature, wave height, wave calibration etc all able to set in software.

3. Solder pot is made of stainless steel with anti-corrosion coating, not leakage. With cast iron heater outside, robust & quick heat up.

4. N2 online heating system, to wet the soldering perfectly and reduce the solder dross.

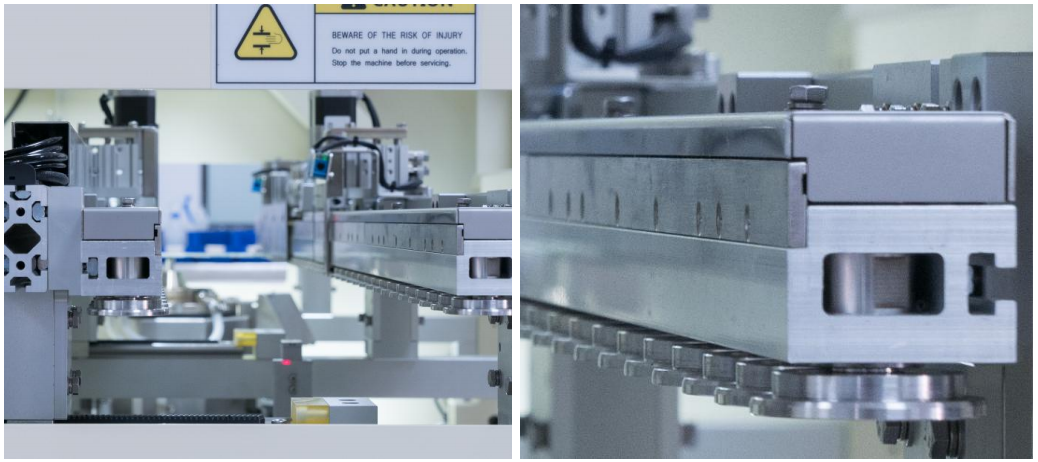

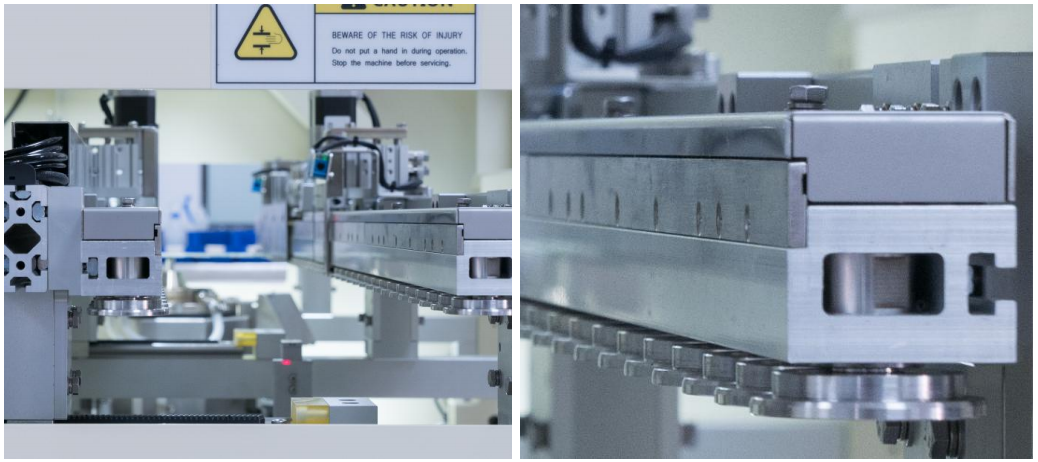

Features 4 Transmission system:

1. Special material profiles ensure stability, and rational design ensures convenience.

2. The transmission module is composed of the roller.

3. PCBA side clamp and top clamp system can ensure the stability of the board.

4. Thickened customized rail, 20KG load.

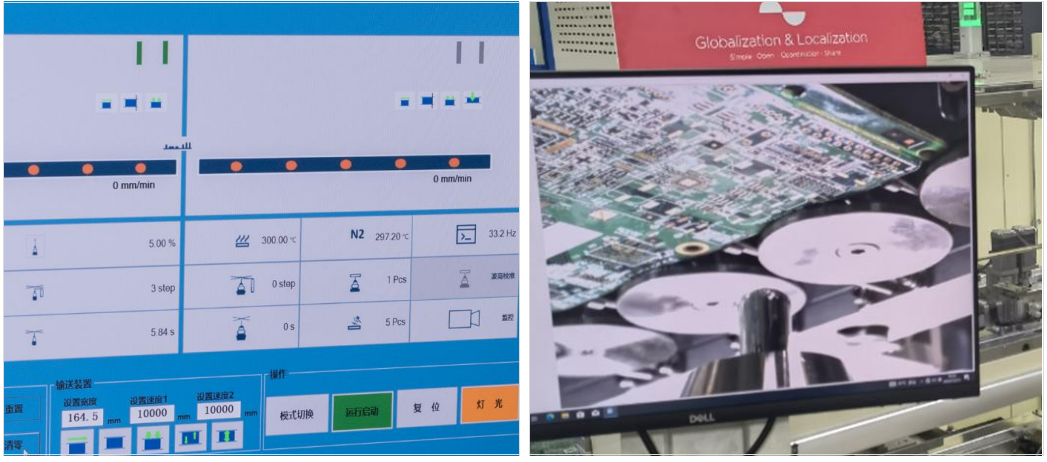

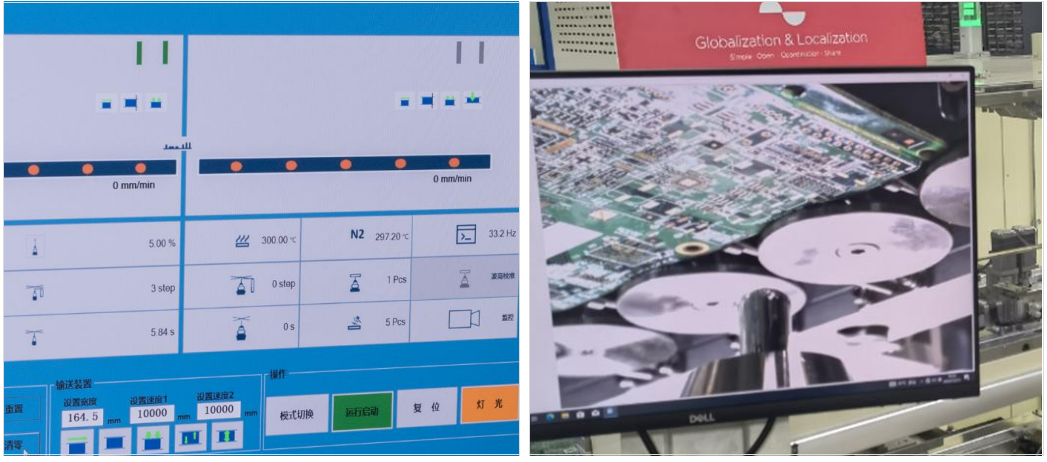

Features 5 Control system:

1. Keyence KV7500 PLC+Keyence module high-end bus control system, ensure the stability and extensibility of the system.

2. Conform to CE and other standards.

3. Underfloor design of Industry 4.0.

4. Ensure the capacity improvement, add the underlying control of the soldering machine module, and ensure the stability.

Features 6 Operating system:

1. Guided programming mode.

2. CCD fast programming function.

3. Picture programming, make coordinate correction, coordinate intelligent verification.

4. Real time data visualization of interface. One button switching of CCD soldering real-time monitoring interface. 5. Chinese, English, can be switched.

Features 7 Intelligence system:

1. Standards and adaptability of MES, WIFI connection, online software upgrade, remote control, intelligent.

2. Soldering data can be traced to confirm the process of each soldering point.

| On-line Selective Wave Soldering Machine |

| Model | I.C.T SS540 | I.C.T SS550 | I.C.T SS550P1

| I.C.T SS550P2 |

| On-line Modular | Spray + Preheating & Soldering | Spray + Preheating + Soldering | Spray + Preheating + Soldering +Soldering | Spray + Preheating + Soldering + Soldering+ Soldering |

| Soldering System |

| Nozzle Quantity | 1

| 1 | 2 | 3 |

| Solder Pot Quantity | 1 set | 1 set | 2 set | 3 set |

| Double Pot (Option) | N/A | Option | Option | Option |

| Solder Pot Power | 2.35kw | 2.35kw | 4.70kw | 7.05kw |

| Flux System |

| Flux Storage Tank | 1L | 1L | 2L | 2L |

| Flux Support | Flux Alarm, Automatic

|

| Spray Nozzle | Germany Jet Valve (Spot and line spraying) 1 set |

| Spray Nozzle Size | 130um (180um, 210um Option) |

| Spray Speed | 0~20mm/s |

| Spray Nozzle Move Speed | 0~400mm/s

|

| Preheating System |

| Preheating Mode | Hot air and IR | Hot air and IR | Hot air and IR | Hot air and IR |

| Preheating Area | L500*W500mm | L500*W500mm | L500*W500mm | L500*W500mm |

| Preheating Zone | Top hot air: 2, Bottom IR: 1 |

| Bottom Preheating Power | Max.12kw |

| Top Preheating Power | Max.6kw |

| Warm-up Time | Approx.15min (setting 150℃) |

| Control Mode | PC+PLC |

| Transport System |

| PCB Size (with fixture) | 120*60~500*500mm |

| PCB Replacement | Online |

| PCB Top Clearance | 120mm |

| Transport Height | 900±20mm |

| Transport Width | 60~500mm |

| Dimension:mm | L1850*W1850*H1480 | L2560*W1750*H1480 | L2560*W1950*H1480 | L2600*W1950*H1480 |

| Weight | Approx: 800kg | Approx: 1200kg | Approx: 1300kg | Approx: 1500kg |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

English

English