Views: 0 Author: I.C.T Publish Time: 2023-03-06 Origin: I.C.T

Smart products have had a transformative impact on society, enabling greater connectivity, convenience, and access to information. They have revolutionized industries such as entertainment and e-commerce, providing new opportunities for businesses and individuals alike. Smart digital products have also facilitated the creation of online communities, promoting social cohesion and empowering marginalized groups. Overall, smart digital products have improved our lives in countless ways and will continue to shape society in positive ways.

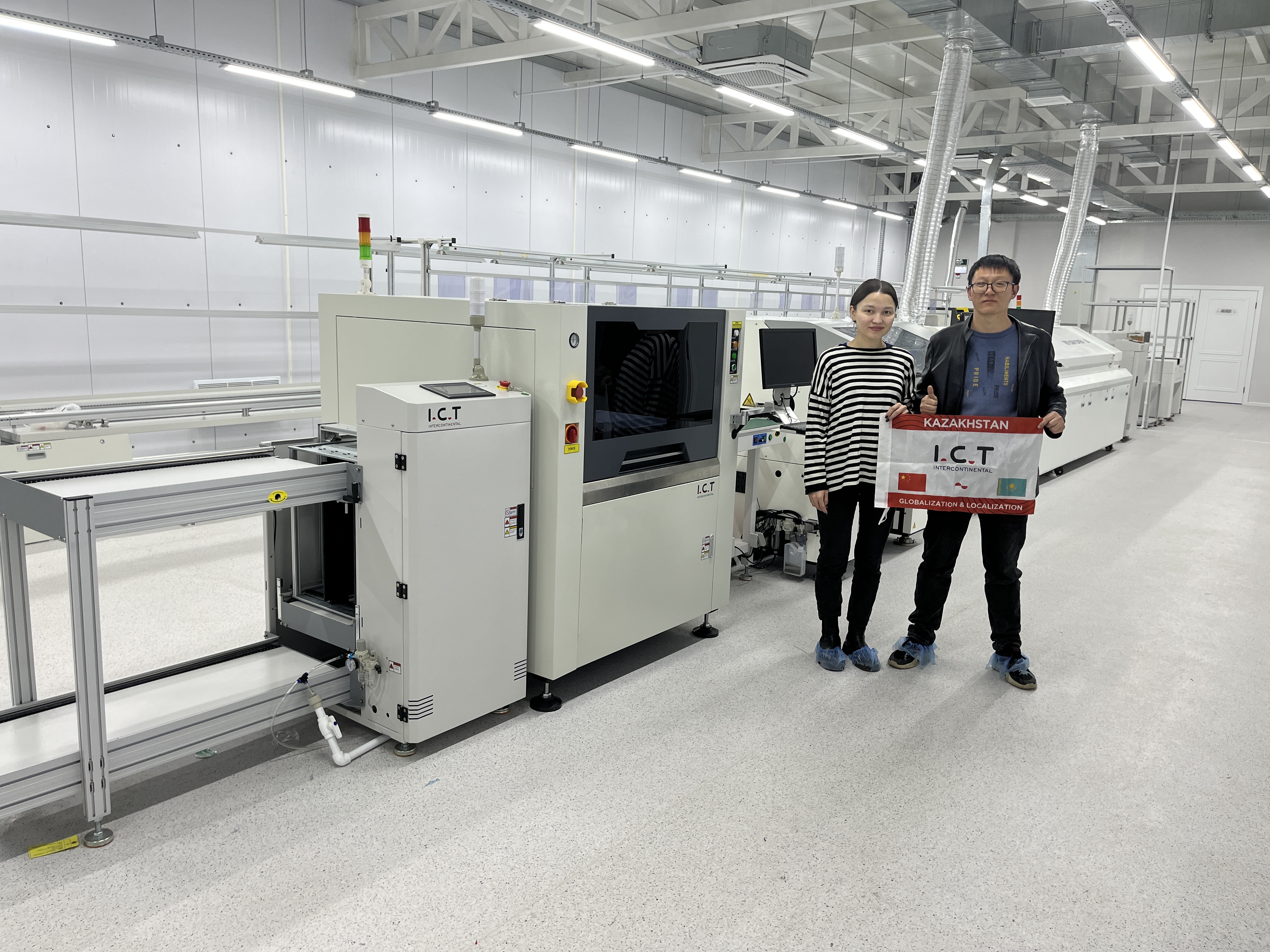

On the bustling streets of Kazakhstan, 2 I.C.T company’s SMT production line and 2 DIP production line equipment were transported to different factories. In February 2023, our engineers arrived in Kazakhstan to establish SMT factories for our two customers.

In 2021, when our customer was preparing to expand their factory, they reached out to I.C.T company. After a preliminary understanding of their production needs, we learned that they produce products such as walkie-talkies, intelligent GPS wearable devices, and other related products. This posed both a challenge and an opportunity for us.

In February 2023, our engineers first arrived at the factory of customer A in Astana, who is a leading provider of critical communication technology solutions with extensive industry experience. They are the frontrunner in the local critical communication market.

Compared to other machines, our PCB printing machine, chip mounter, reflow soldering machine, wave solder machine are subject to higher demands from customers to ensure the production of high-quality products.Additionally, we work closely with our customers to understand their specific production requirements and tailor our machines to meet those needs.

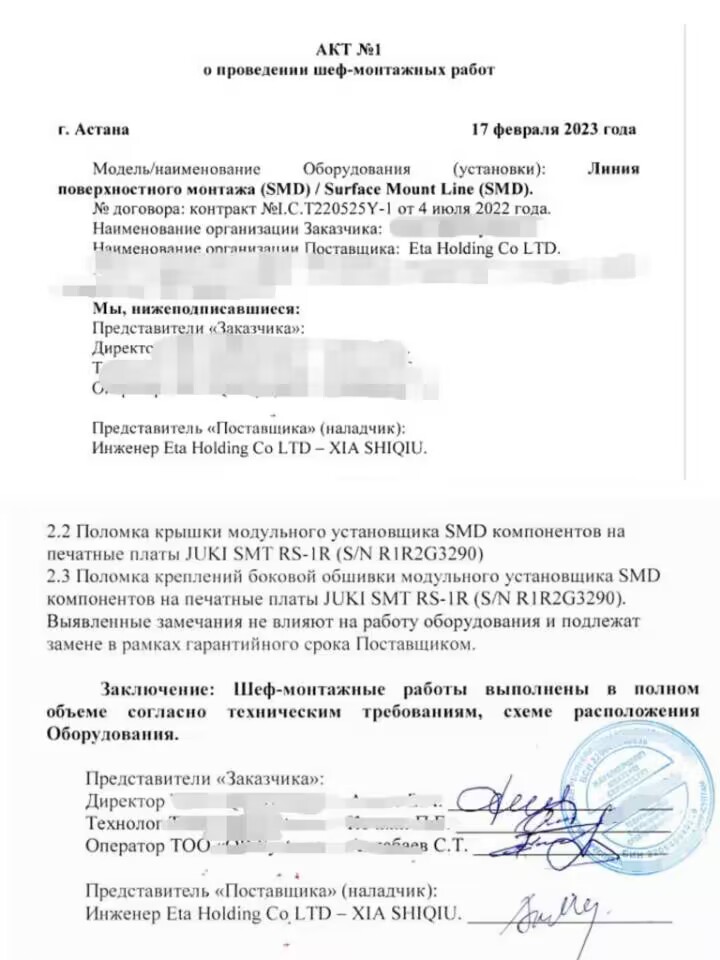

Through active communication between our professional engineers and the customer, and by taking into account the customer's future production capacity, we customized a suitable fully automatic JUKI SMT line and DIP line for the customer. This included equipment such as solder paste mixers, SMT stencil printer, SMT PCB loader and unloader, JUKI pick and palce machine, L8 reflow oven, PCB conveyor, DIP insertion Line, W2 wave soldering machine, wave loader, wave unloader,belt assembly line, and offline selective soldering machine.

This client was so efficient that we had the opportunity to visit them in Kazakhstan in December 2022.The image on the left was taken in December and the one on the right in February, and the difference between the two images is striking.

The factory is equipped with cutting-edge facilities, and our engineers worked tirelessly to ensure that the installation of the JUKI SMT line is seamless. With the establishment of the SMT factory, Customer A will be able to significantly increase their production capacity and meet the growing demand for their products in the market.

During our time in Kazakhstan, our team of engineers has been busy not only helping customer A establish an SMT factory, but also providing support at another local customer's factory.

Smart home products, such as smart doorbells and smart surveillance cameras, In the local market, these products have gained significant traction as consumers seek to upgrade their homes with the latest technology.

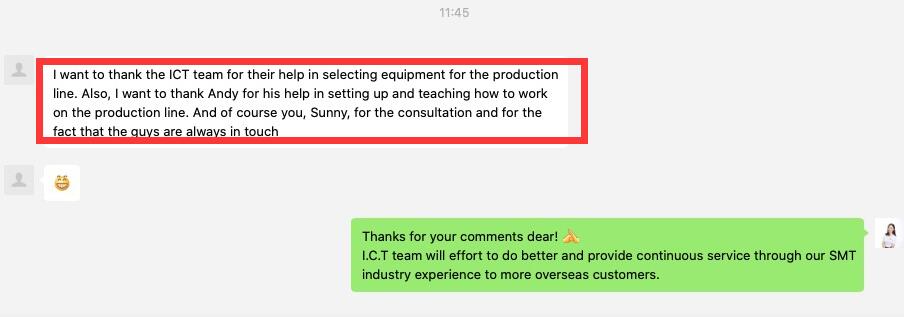

After our engineers arrived in Kazakhstan in February 2023, they quickly helped our customers set up the SMT and DIP production lines and resolved issues related to the production process of smart home security products.

Customers have a deep understanding of their products. They purchased our SMT production line machines in 2020, and this time they want to further improve the production efficiency of their products and reduce production costs. They planned the production strategy for the next 3-5 years in advance. Therefore, we provide them with different equipment configuration options, including adding a JUKI placement machine, and configuring a 54mm/27mm vision camera on the basis of the existing camera, which has a wider application range. We continue to invest in our SMT machines and people to ensure we meet our customers' changing needs and help them achieve their goals.

The equipment includes, but is not limited to, SMT PCB loader unloader, full-auto PCB printer, 2 JUKI RS-1R chip mounter (Double sides), PCB reflow oven, PCB conveyor, automatic insertion line, DIP wave soldering machine, wave loader, wave unloader, etc.

It's worth mentioning that our customer from Oregon State University first contacted us in 2018 and went on to purchase our full automatic SMT production line and DIP line equipment in 2019. In 2022, Oregon State University conducted market research and found that there is a huge market for SMT in Kazakhstan. To meet the growing demand for SMT professionals, they decided to establish a new SMT factory in Kazakhstan. Based on their trust in our professionalism, service, and products, they once again chose I.C.T and purchased another full automatic production line and DIP production line from us to be installed in their new factory.

Our team worked closely with the customer to ensure that the equipment was customized to their specific needs, and provided training to their staff to ensure that they were able to operate the equipment safely and efficiently.