I.C.T- FAI1095

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Overview

Overview

Introduction:

I.C.T-FAI1095 is an advanced PCBA full-automatic flying probe test first article tester. It subverts the traditional manual material clamping test. It adopts the flying probe detection method, combined with software to realize fully automatic material clamping detection components, and automatically enters and exits the board. The efficiency is 5 times that of the traditional FAI first article detector, which reduces the time of production line changeover and improves the utilization rate of the production line.

1. The machine replaces the labor, and automatically detects the LCR. The detection process does not require manual participation, saving manpower. Increase the speed by at least 3-5 times, with an average of 1 second per component. The more components on the board, the more obvious the advantage.

2. Using advanced artificial intelligence system, it can identify wrong/repeated BOM consumption, multiple pieces, small pieces, reverse, wrong materials, etc., and the detection data will be displayed synchronously in real time, effectively preventing human errors and omissions.

3. The test process is fully automatic test judgment, no need to manually insert materials, no need to switch ranges, no need to manually compare the measured values, the system automatically judges PASS and FAIL.

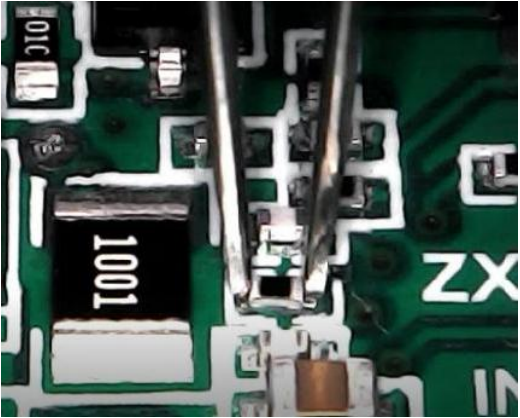

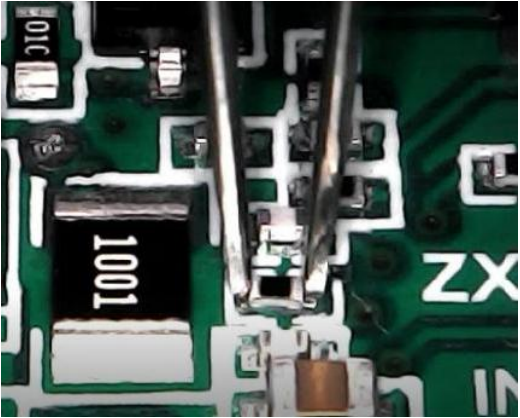

4. The equipment can obtain PCBA high-definition graphics, which can magnify the real object dozens of times. There are silk screen and directional components. The system automatically performs optical comparison detection without manual participation.

5. The real-time record of the test process cannot be modified, and the detection scene can be restored, which is easy to trace; and it can support user permission definition to prevent misoperation.

6. It can automatically generate a complete test report, and the test report can be selected and output in Excel and PDF formats, and is equipped with component images and PCBA related information.

7. Compatible with various formats of BOM.

8. Sampling inspection or refueling sampling inspection, according to the station location sampling inspection function, can conduct random inspection according to the station location table, BOM table, or midway refueling sampling inspection.

9. MES docking function, the report can be docked with the customer's MES system, just upload it on the computer.

10. Auxiliary function of drawing design, the system can color and mark the drawing, and the marking content includes tag number, standard value, precision and specification. 11. Power-off protection function.

Fully automatic flying probe detection

The software automatically identifies BOM and coordinate information, automatically adjusts the size and angle of components, and automatically measures through flying probes, eliminating the need for manual measurement in the entire process.

Automatic recognition and judgment

Automatic visual comparison for IC chips, diodes, transistors, resistors, capacitors and other components containing characters. Resistor screen printing can be detected with one click, and the programming process is simple and fast. The program can be programmed once and reused multiple times.

Automatically Determining The Detection Result

System receives from data of digital bridge and automatically judges PASS(correct) or FALL(wrong), and the artificial judgment of PASS via computer can be conducted. The detection result is of real-time display, with missing inspection completely eradicated.

ERP And MES Docking Function

The report can be connected to the customer's ERS\MES system, uploaded through the computer, and the results can be monitored and traced in real time.

| Model | I.C.T-FAI1095 |

| PCB Size(mm) | M: 350mm*450mm |

| PCB Height | Up 25mm, Bottom 50mm |

| Accuracy | 0.05% |

| Measurement Display Range | R: 0.01m ohms ~ 99.9999M ohms L: 0.01nH ~ 9999.9H C: 0.00001pF ~ 9.9999F |

| Average Detection Speed | 1 seconds/component |

| Detect Coverage Type | Data type: wrong BOM usage, repeated positions, missing definition of XY coordinates, multiple definitions; Circuit board: multiple pastes, missing parts, wrong parts, reverse, rollover, offset, rotation, etc. |

| SPC Process Control | The test data is recorded throughout the process, and reports in Excel and PDF formats can be output, and the test scene can be restored in the later stage to provide traceability basis. |

| Component Angle | Support 0°, 90°, 180°, 270° components and 45°, 135°, 225° and other oblique parts. |

| Server Mode | Using a central database, the data of multiple FAIs can be managed in a centralized manner |

| Power Supply | AC220V, 50/60Hz, less than 1.5KVA |

| Outline Dimensions | 1085*1122*1638mm |

| Weight | 700KG |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Overview

Overview

Introduction:

I.C.T-FAI1095 is an advanced PCBA full-automatic flying probe test first article tester. It subverts the traditional manual material clamping test. It adopts the flying probe detection method, combined with software to realize fully automatic material clamping detection components, and automatically enters and exits the board. The efficiency is 5 times that of the traditional FAI first article detector, which reduces the time of production line changeover and improves the utilization rate of the production line.

1. The machine replaces the labor, and automatically detects the LCR. The detection process does not require manual participation, saving manpower. Increase the speed by at least 3-5 times, with an average of 1 second per component. The more components on the board, the more obvious the advantage.

2. Using advanced artificial intelligence system, it can identify wrong/repeated BOM consumption, multiple pieces, small pieces, reverse, wrong materials, etc., and the detection data will be displayed synchronously in real time, effectively preventing human errors and omissions.

3. The test process is fully automatic test judgment, no need to manually insert materials, no need to switch ranges, no need to manually compare the measured values, the system automatically judges PASS and FAIL.

4. The equipment can obtain PCBA high-definition graphics, which can magnify the real object dozens of times. There are silk screen and directional components. The system automatically performs optical comparison detection without manual participation.

5. The real-time record of the test process cannot be modified, and the detection scene can be restored, which is easy to trace; and it can support user permission definition to prevent misoperation.

6. It can automatically generate a complete test report, and the test report can be selected and output in Excel and PDF formats, and is equipped with component images and PCBA related information.

7. Compatible with various formats of BOM.

8. Sampling inspection or refueling sampling inspection, according to the station location sampling inspection function, can conduct random inspection according to the station location table, BOM table, or midway refueling sampling inspection.

9. MES docking function, the report can be docked with the customer's MES system, just upload it on the computer.

10. Auxiliary function of drawing design, the system can color and mark the drawing, and the marking content includes tag number, standard value, precision and specification. 11. Power-off protection function.

Fully automatic flying probe detection

The software automatically identifies BOM and coordinate information, automatically adjusts the size and angle of components, and automatically measures through flying probes, eliminating the need for manual measurement in the entire process.

Automatic recognition and judgment

Automatic visual comparison for IC chips, diodes, transistors, resistors, capacitors and other components containing characters. Resistor screen printing can be detected with one click, and the programming process is simple and fast. The program can be programmed once and reused multiple times.

Automatically Determining The Detection Result

System receives from data of digital bridge and automatically judges PASS(correct) or FALL(wrong), and the artificial judgment of PASS via computer can be conducted. The detection result is of real-time display, with missing inspection completely eradicated.

ERP And MES Docking Function

The report can be connected to the customer's ERS\MES system, uploaded through the computer, and the results can be monitored and traced in real time.

| Model | I.C.T-FAI1095 |

| PCB Size(mm) | M: 350mm*450mm |

| PCB Height | Up 25mm, Bottom 50mm |

| Accuracy | 0.05% |

| Measurement Display Range | R: 0.01m ohms ~ 99.9999M ohms L: 0.01nH ~ 9999.9H C: 0.00001pF ~ 9.9999F |

| Average Detection Speed | 1 seconds/component |

| Detect Coverage Type | Data type: wrong BOM usage, repeated positions, missing definition of XY coordinates, multiple definitions; Circuit board: multiple pastes, missing parts, wrong parts, reverse, rollover, offset, rotation, etc. |

| SPC Process Control | The test data is recorded throughout the process, and reports in Excel and PDF formats can be output, and the test scene can be restored in the later stage to provide traceability basis. |

| Component Angle | Support 0°, 90°, 180°, 270° components and 45°, 135°, 225° and other oblique parts. |

| Server Mode | Using a central database, the data of multiple FAIs can be managed in a centralized manner |

| Power Supply | AC220V, 50/60Hz, less than 1.5KVA |

| Outline Dimensions | 1085*1122*1638mm |

| Weight | 700KG |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT