X-7200

I.C.T

X-ray inspection machine

| Availability: | |

|---|---|

| Quantity: | |

I.C.T X-7200 inspection machine has a wide range of applications. It is commonly used in the internal structure testing of electronic components, common air bubble void rate measurement, circuit short circuit open circuit, solder joint lack of soldering and missing soldering, foreign matter

cracks inside, etc.

It has the characteristics of convenient maintenance and long service life; simple operation, reducing operator training; high repeatability of detection; allowing a maximum viewing angle of 60 degrees to detect samples and so on.

Features:

In the world of advanced electronics manufacturing, precision and quality control are paramount. The I.C.T X-7200 X-Ray Machine stands as a testament to innovation and excellence, offering a plethora of features that set it apart as an indispensable asset in your SMT plant. Let's explore the exceptional attributes that define the X-7200:

1. High-Resolution Imaging:

The X-7200 boasts an astounding imaging accuracy of 85μm, setting a high bar for precision.

Its resolution can reach an impressive 5μm, ensuring that even the finest details are revealed with remarkable clarity. Every component, every connection – scrutinized with precision.

2. Versatile Magnification:

This machine provides a maximum magnification of 200x, offering detailed inspections that leave no room for hidden defects.

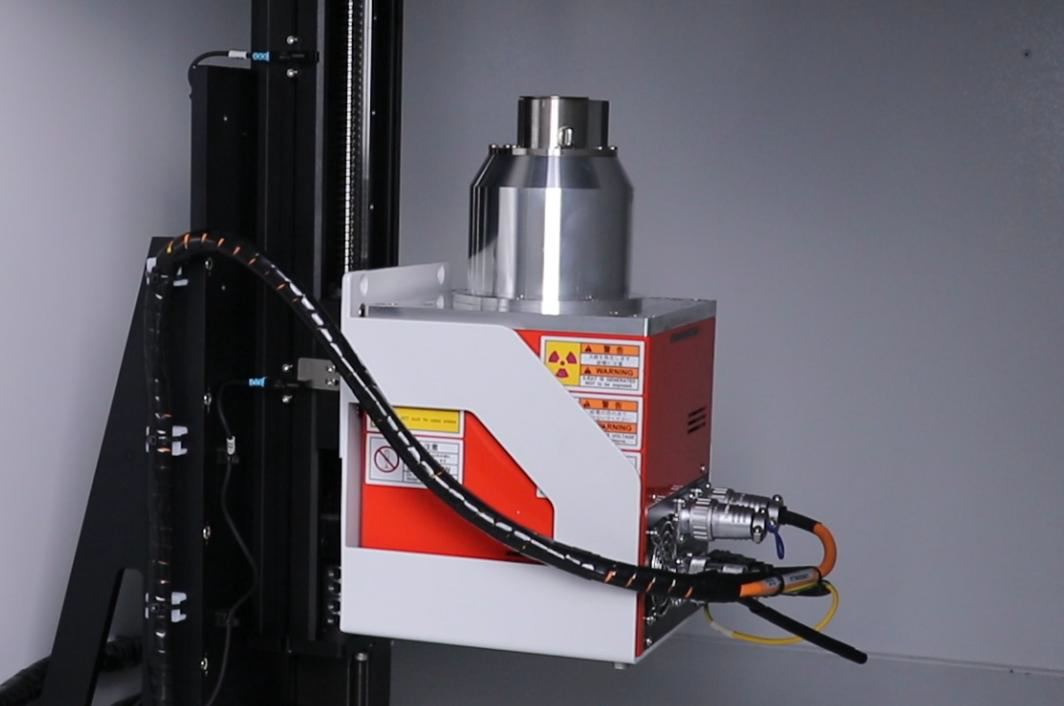

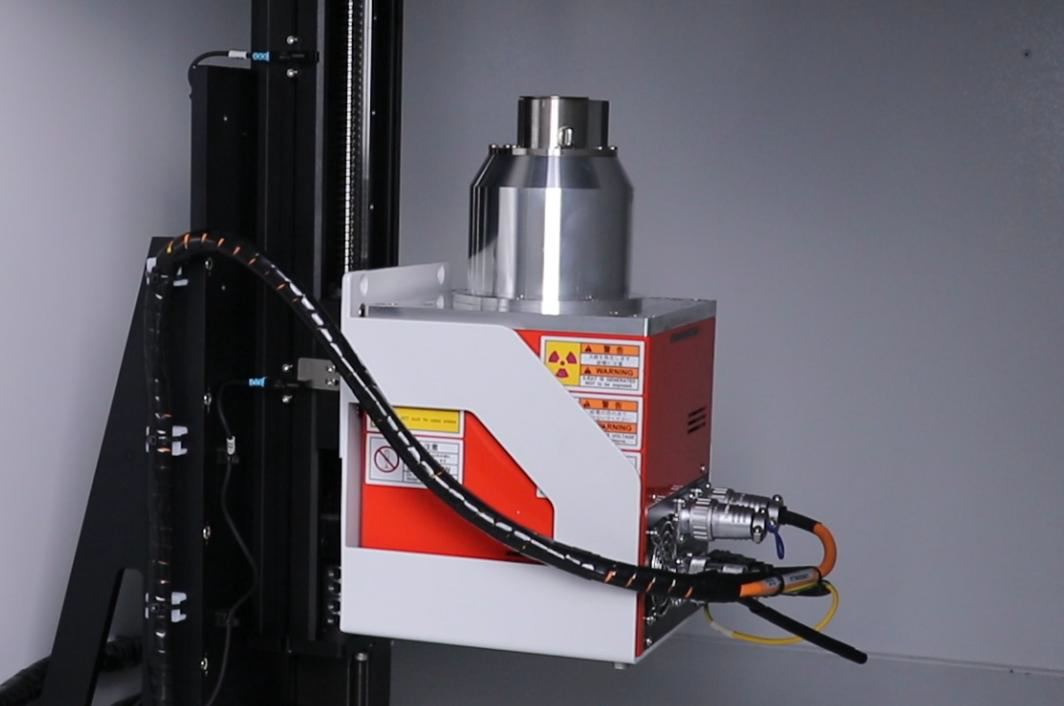

3. Trusted X-Ray Source:

The X-7200 utilizes a 90kV closed tube, featuring a renowned Japanese brand – Hamamatsu. This guarantees stable and high-quality X-ray emission.

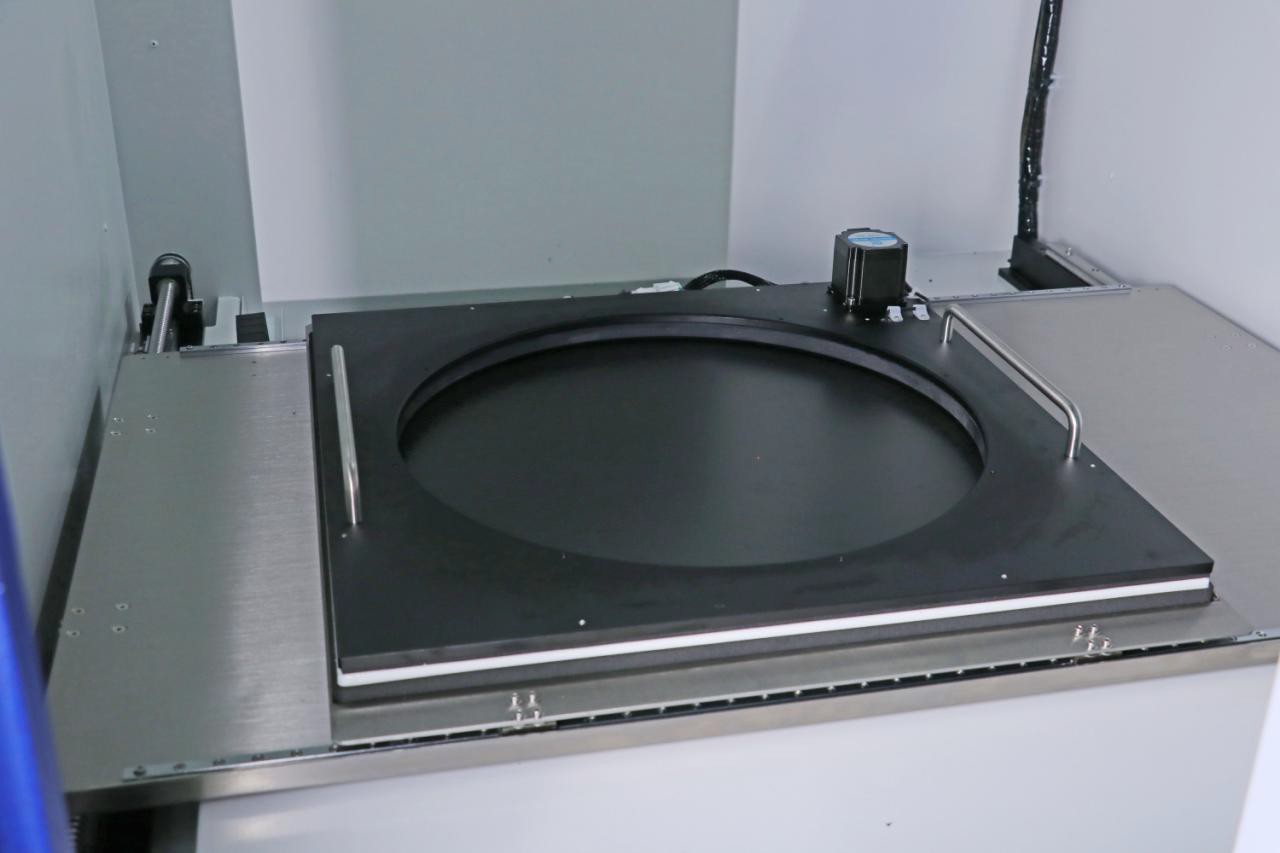

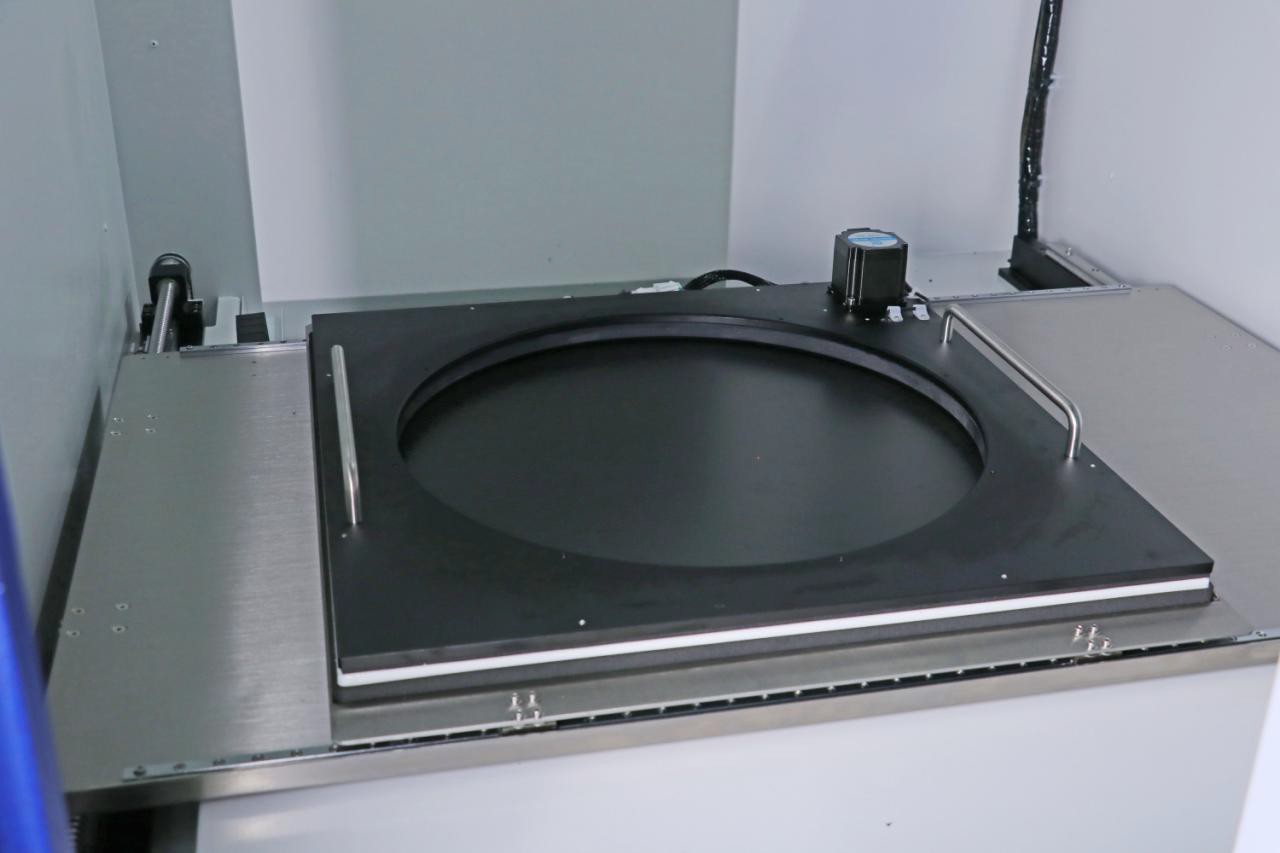

4. Spacious Platform:

Accommodating 540*540mm, the platform is versatile enough to cater to the inspection needs of the majority of electronic products.

5. Intuitive User Interface:

The user-friendly software is designed with a visual navigation interface. Inspection results are presented with color-coded patterns, making it easier than ever to identify key features.

The I.C.T X-7200 X-Ray Machine is not just an inspection tool; it's a precision instrument that empowers you to elevate your quality control processes, streamline manufacturing, and uphold the highest standards of quality in electronics production. With the X-7200 by your side, excellence becomes your standard.

Joystick Control

Programming Control

Optional: Digital HD X-RAY flat detector

XRAY Tube

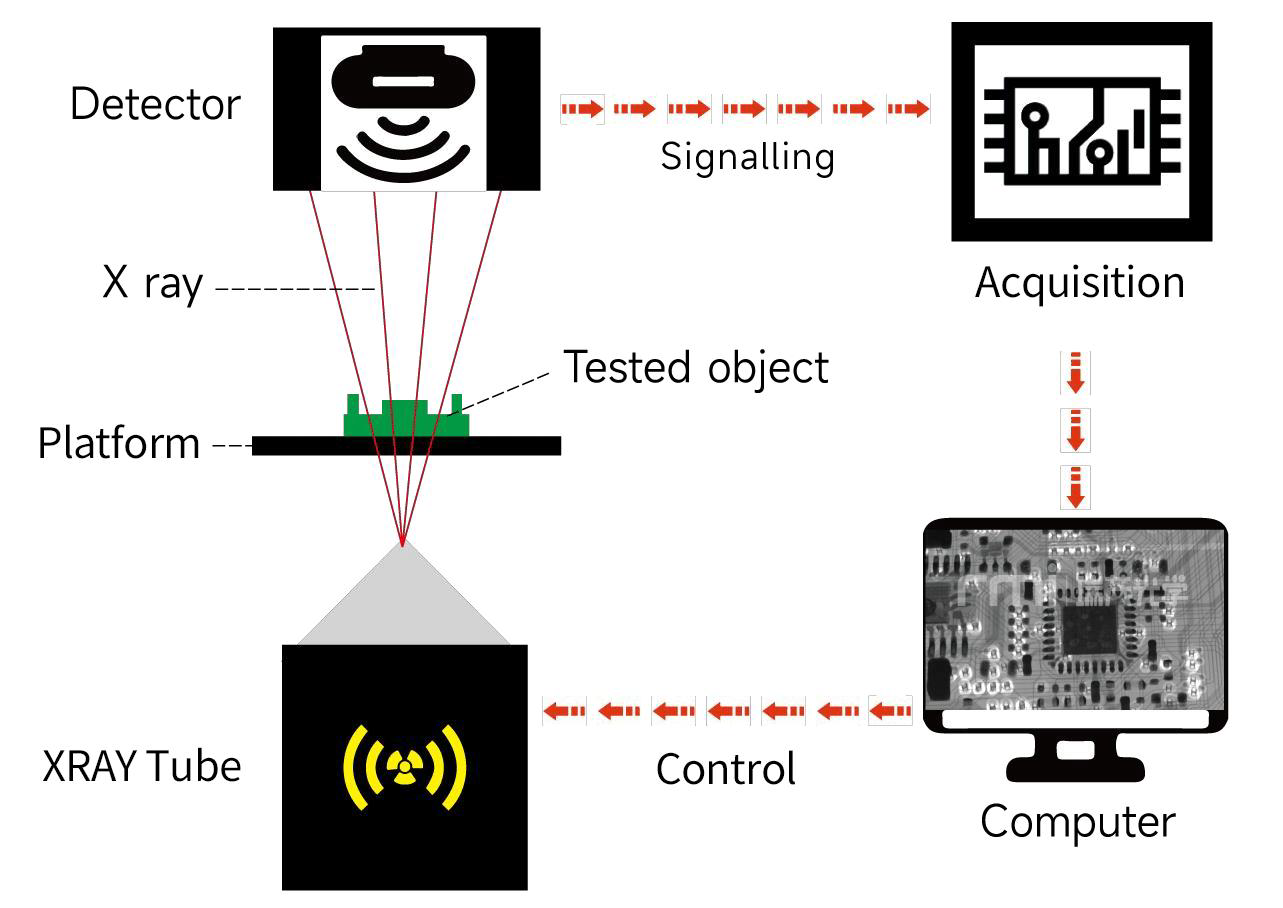

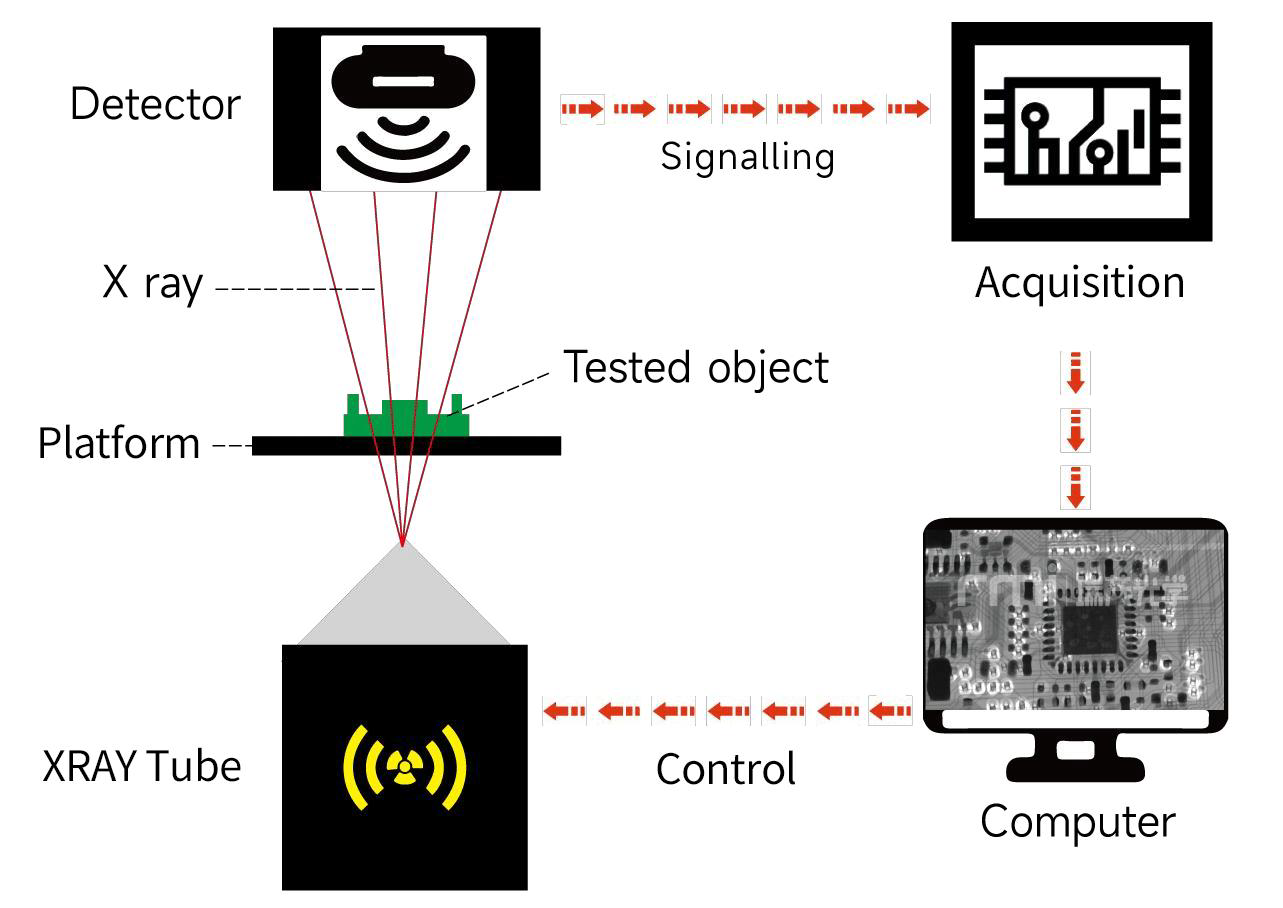

The computer controls the intensity of the XRAY tube emitted by the XRAY, penetrates the Tested object, reaches the Detector, and the Image Acquisition card converts the signal and sends it back to the computer.

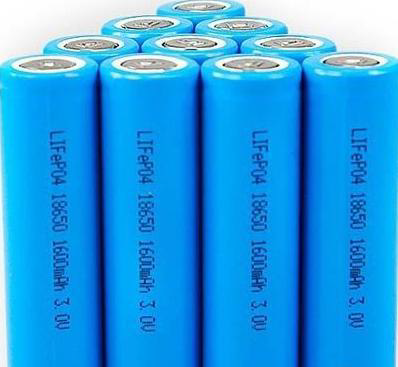

SMT, BGA, PCBA assembly, Router, Lithium battery, Wire harness, Wire rod, Display, Fuse, Electronic components, Automotive parts, Photo-voltaic, Aluminium die-casting, Moulding plastic, Ceramics, other special industries.

Router

Wire rod

Electronic harness

Electronic sensor

Battery protection board

Display

Lithium battery

Fuse

| Item | Model | I.C.T X-7200 |

| X-Ray Tube | Type | Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T X-7200 inspection machine has a wide range of applications. It is commonly used in the internal structure testing of electronic components, common air bubble void rate measurement, circuit short circuit open circuit, solder joint lack of soldering and missing soldering, foreign matter

cracks inside, etc.

It has the characteristics of convenient maintenance and long service life; simple operation, reducing operator training; high repeatability of detection; allowing a maximum viewing angle of 60 degrees to detect samples and so on.

Features:

In the world of advanced electronics manufacturing, precision and quality control are paramount. The I.C.T X-7200 X-Ray Machine stands as a testament to innovation and excellence, offering a plethora of features that set it apart as an indispensable asset in your SMT plant. Let's explore the exceptional attributes that define the X-7200:

1. High-Resolution Imaging:

The X-7200 boasts an astounding imaging accuracy of 85μm, setting a high bar for precision.

Its resolution can reach an impressive 5μm, ensuring that even the finest details are revealed with remarkable clarity. Every component, every connection – scrutinized with precision.

2. Versatile Magnification:

This machine provides a maximum magnification of 200x, offering detailed inspections that leave no room for hidden defects.

3. Trusted X-Ray Source:

The X-7200 utilizes a 90kV closed tube, featuring a renowned Japanese brand – Hamamatsu. This guarantees stable and high-quality X-ray emission.

4. Spacious Platform:

Accommodating 540*540mm, the platform is versatile enough to cater to the inspection needs of the majority of electronic products.

5. Intuitive User Interface:

The user-friendly software is designed with a visual navigation interface. Inspection results are presented with color-coded patterns, making it easier than ever to identify key features.

The I.C.T X-7200 X-Ray Machine is not just an inspection tool; it's a precision instrument that empowers you to elevate your quality control processes, streamline manufacturing, and uphold the highest standards of quality in electronics production. With the X-7200 by your side, excellence becomes your standard.

Joystick Control

Programming Control

Optional: Digital HD X-RAY flat detector

XRAY Tube

The computer controls the intensity of the XRAY tube emitted by the XRAY, penetrates the Tested object, reaches the Detector, and the Image Acquisition card converts the signal and sends it back to the computer.

SMT, BGA, PCBA assembly, Router, Lithium battery, Wire harness, Wire rod, Display, Fuse, Electronic components, Automotive parts, Photo-voltaic, Aluminium die-casting, Moulding plastic, Ceramics, other special industries.

Router

Wire rod

Electronic harness

Electronic sensor

Battery protection board

Display

Lithium battery

Fuse

| Item | Model | I.C.T X-7200 |

| X-Ray Tube | Type | Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT