Views: 0 Author: Site Editor Publish Time: 2023-08-07 Origin: Site

Our Malaysian customer is a leading manufacturer of LED lighting products, renowned for continuous innovation and high-quality offerings, which have earned them an excellent reputation in the market. To meet the growing market demands and enhance production efficiency, the customer decided to invest in an advanced SMT Production Line to achieve higher levels of automation and precision manufacturing.

In the rapidly evolving LED Industry, our company, I.C.T, provided a brand-new SMT production line to our Malaysian customer for their LED lens project. The SMT production line is equipped with various SMT equipment, including a semi-automatic stencil printer, SMT conveyor, online LED LENS dispensing machine, Samsung / Hanwha pick and place machine, 8-zone reflow oven, Bowl feeder, Samsung original feeder, and a cooling conveyor.

We offer comprehensive solutions to meet diverse product manufacturing needs. Contact us for more flexible solutions.

As a specialized provider in the SMT Industry, our I.C.T company understood the customer's requirements and offered a comprehensive solution. After thorough communication with the customer, our technical team recommended a customized SMT production line. This production line combines professional technology and efficient equipment to fulfill different demands during the LED lens manufacturing process.

The semi-auto SMT stencil printer and online LED LENS dispensing machine ensure high precision and stability during printing and dispensing. The coordination between the Samsung pick and place machine and Bowl feeder increases pick-and-place efficiency and accuracy. Additionally, the 8-zone SMT reflow oven guarantees consistent and high-quality soldering. These well-coordinated devices provide the customer with an efficient and high-quality LED lens production solution.

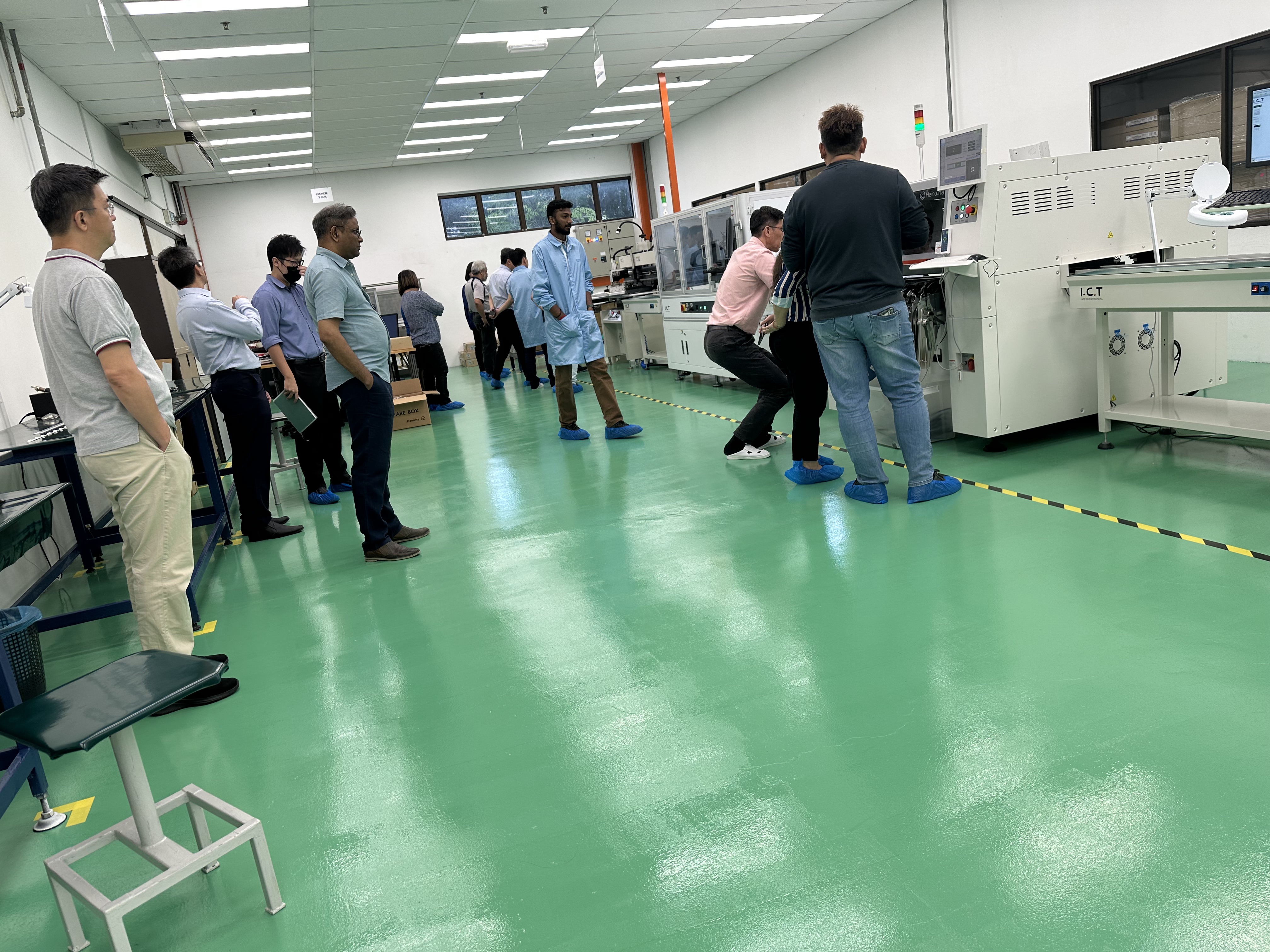

Upon finalizing the production line configuration, we promptly completed the manufacturing of the equipment and shipped it to the customer's facility in Malaysia. On July 13th, our engineer Lucas traveled to Malaysia to oversee the installation and debugging of the production line. Lucas skillfully adjusted the equipment on-site to ensure its smooth operation.

We understand the significance of training and technical support for the production line operators. Therefore, before the production line was put into operation, we provided comprehensive training to the customer's staff, covering equipment operation, routine maintenance, and troubleshooting. We ensured that the customer's team became proficient in operating the production line within a short period and equipped them to handle any potential issues effectively.

Since the deployment of the new SMT production line, the customer has experienced remarkable returns and benefits. The high automation and stability of the production line significantly improved LED lens production efficiency and reduced waste.

With our extensive experience and expertise in the SMT industry, I.C.T can offer comprehensive solutions to meet various product manufacturing needs for our customers.

For you we can provide Full SMT Line Solution, DIP Line Solution and Coating Line Solution with best quality and service.

More information about I.C.T please contact US at info@smt11.com